Blog

More to learn about rapid prototyping and manufacturing industry.

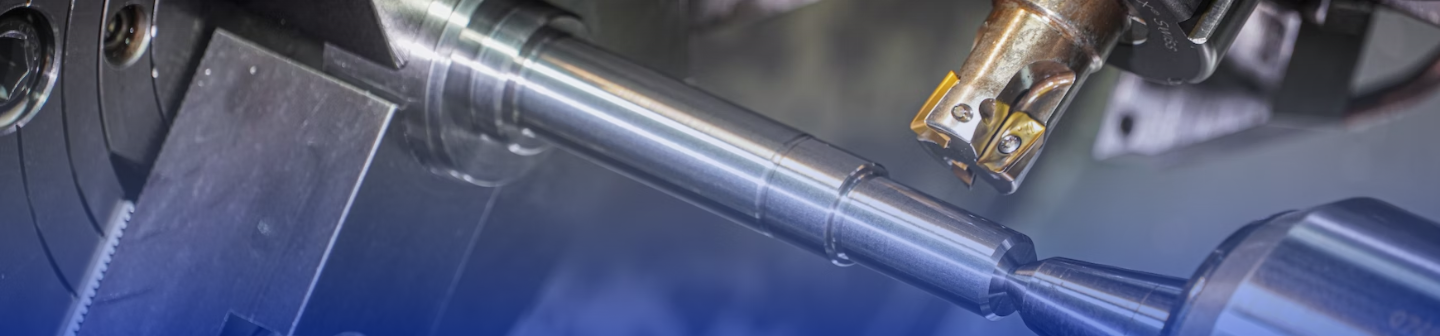

CNC Tool Path Design: Principles, Strategies, and Best Practices for Precision Machining

Efficient and precise tool path design is fundamental to modern machining, ensuring both productivity and high-quality surface finishes. From roughing to finishing, selecting the appropriate tools, feed rates, cutting depths, and clamping methods directly impacts machining accuracy, tool life, and workpiece integrity.

Research on Process and Performance of Electric Brush Plating Sulfuric Acid Anodizing

Aluminum and aluminum alloys possess high specific strength, excellent plasticity, superior electrical and thermal conductivity, outstanding machinability, and corrosion resistance.

Injection-Molded Connector Warpage Control: Material and Process Optimization

As a critical component of electronic devices and systems, connectors have seen technological advancements in recent years aligned with industry trends. Miniaturization represents one key development direction for connectors, addressing space constraints.

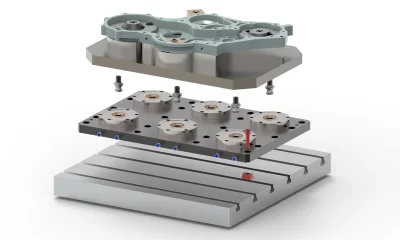

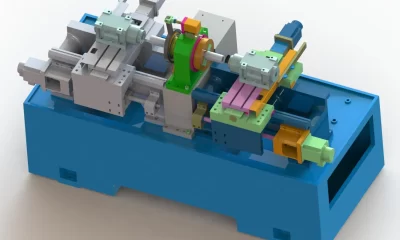

Prospects for the Application of Zero-Point Quick-Change Fixtures Based on Intelligent Manufacturing in Machining

Faced with increasing production demands year after year, under existing conditions, improving production efficiency and maximizing machine tool utilization have become the ongoing focus of the technical department.

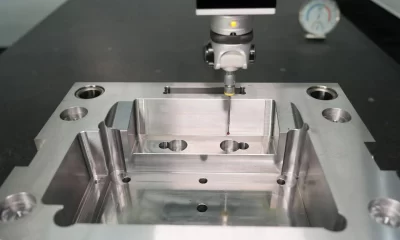

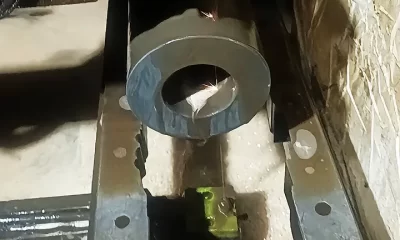

Design and Application of a Downward-Pressing External Clamping Fixture for the Slide Table of a CNC Honing Machine

Cylinder liners are core components of an engine, playing a crucial role in ensuring stable operation, enhancing performance, and extending service life.

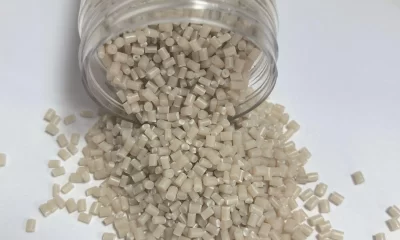

Typical Shrinkage Rates for Common Plastics

The molding shrinkage rate of plastic products refers to the percentage reduction in the room-temperature dimensions of a plastic part after it is removed from the mold and cooled to room temperature, relative to its original uncooled dimensions.

Milling Machining Methods, Strategies, and Formulas

Milling machining encompasses a diverse range of methods and strategies, from basic operations like face milling and slot milling to advanced techniques such as high-speed, high-performance, and micro-machining.

What is Precision Injection Molding?

Precision injection molding, strictly speaking, refers to an injection molding production method where the dimensional accuracy of plastic products manufactured via injection molding equipment can achieve tolerances below 0.01mm, typically ranging between 0.01mm and 0.001mm.

Properties and Processing of Plastics such as PS, HIPS, and PMMA

This article provides an overview of the fundamental properties and processing characteristics of commonly used injection-molding plastics.

Clamping Method for Through-Hole Chamfering of High-Precision Plastic Sheets

The design requirements for thin-walled, thin-plate structural components are to reduce product weight while ensuring structural strength. This paper investigates and analyzes the milling process of high-precision plastic thin plates.

Design and Implementation of an Automated Bending Workstation for Metal Sheets

Sheet metal fabrication falls under the category of cold working processes, encompassing a series of operations including blanking, cutting, punching, bending, and riveting.

Expert Tungsten Alloy Manufacturing Insights You Won’t Want to Miss

On any engineer's list of “nightmare materials,” tungsten alloys rank high. Their high density and extreme hardness make machining a grueling battle at every stage. How can we achieve an efficient leap from raw blank to precision part with this tough nut to crack?