RAPID PROTOTYPING AND MASSIVE PRODUCTION, METAL AND PLASTIC.

Custom Parts, On Demand Manufacturing

Get high-quality, quick delivery and professional engineering service from an experienced manufacturer.

Our On-Demand Manufacturing Services

From rapid prototyping to mass production, we manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

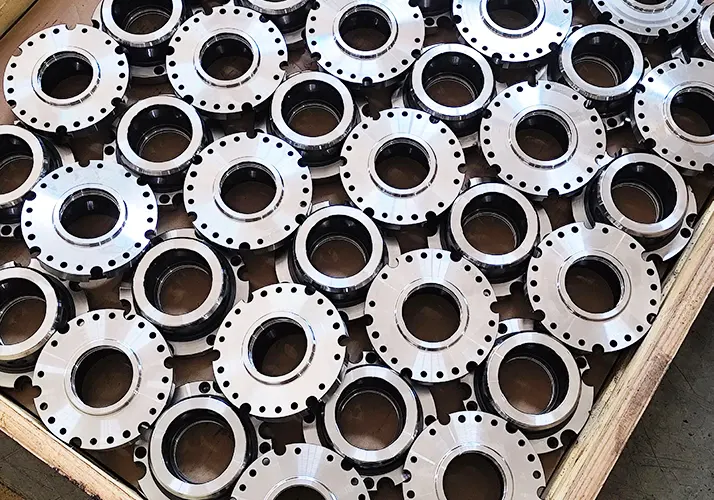

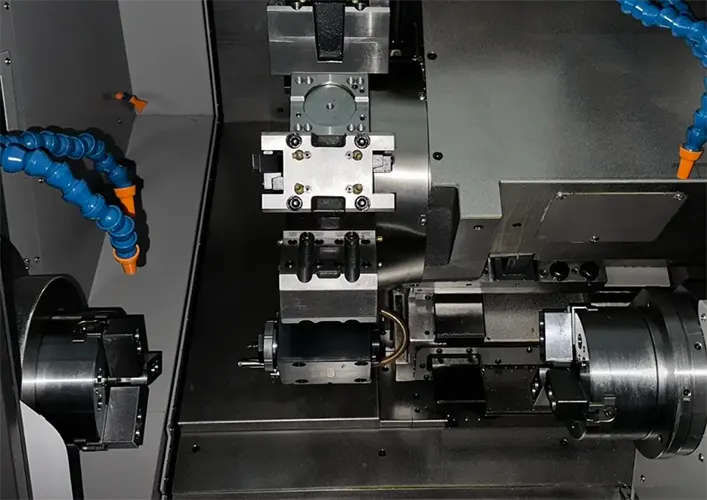

CNC Machining

Computer numerical control machines produce complex parts with great accuracy and consistency. CNC machining excels in efficiently handling single pieces, small batches, and mass production with remarkable precision and expertise.

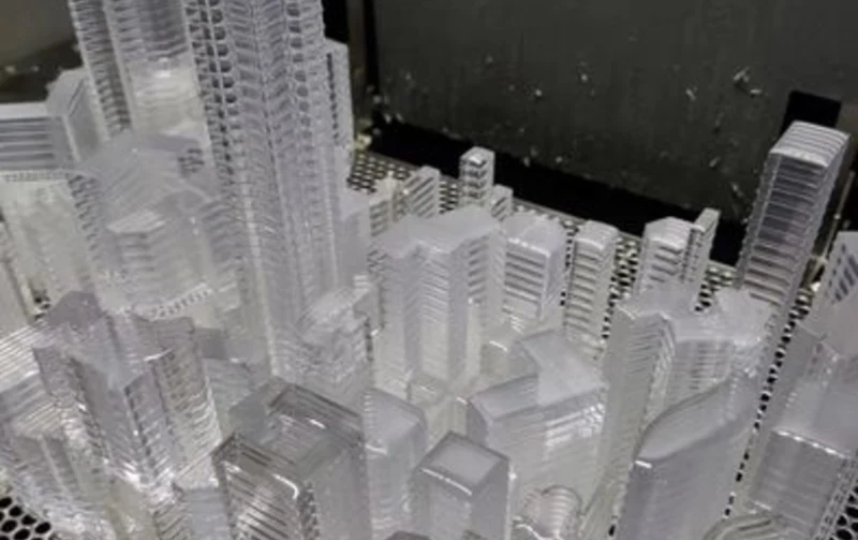

Rapid Prototyping

Rapid prototyping encompasses several technologies that can efficiently produce a small number of parts at a low cost. These technologies include different 3D printing methods and urethane casting.

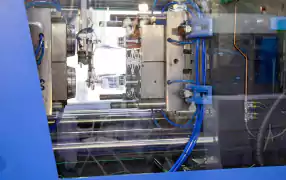

Injection Tooling

We’re experts in both rapid mold and production mold manufacturing. Our rapid mold option is ideal for making a small number of plastic products, typically between 1000 to 30000 shots. On the other hand, our production mold service is specifically tailored for large-scale projects that require over 30K shots.

Injection Molding

Injection molding is used for producing a wide array of plastic products ranging from bottle caps to automotive parts. It is the most common process to make plastic parts.

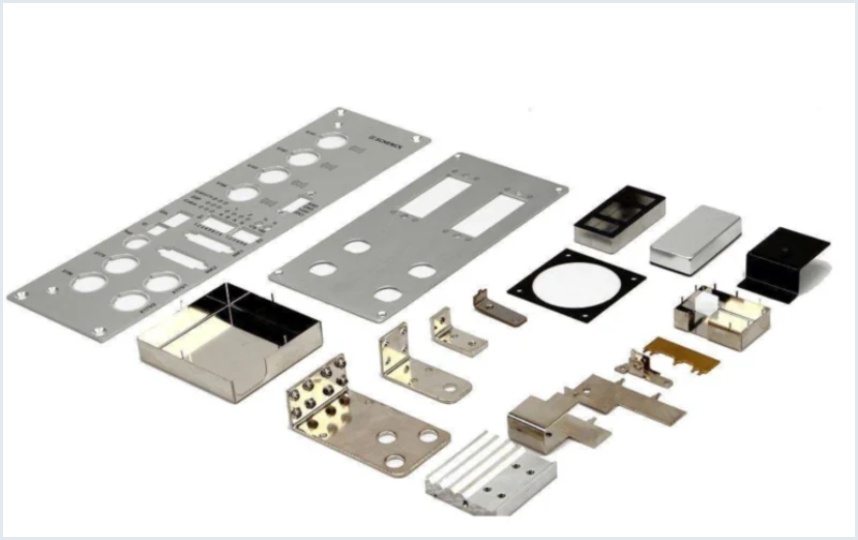

Sheet Metal Fabrication

Sheet metal fabrication is a process where flat sheets of metal are transformed into various useful components and structures. It involves cutting, bending, and shaping the metal to create the desired shapes and sizes.

High-Pressure Die-casting

Most common process to make metal parts in volume. Most common used materials are Aluminum Alloy, Zinc Alloy and Magnesium Alloy.

Our Robust Capabilities Behind Numbers

Companies Served

Unique Parts Produced

Countries Shipped

Years in Business

Suppliers Cooperated

How To Work With Us?

To start, select a service, Upload a .stp file. and Within a couple of hours, we’ll send you the Engineering analysis (DFM) and prices. Upon your agreement, We’ll start the manufacturing Process. Parts shall be made, And delivered to you. In a couple of days.

1. Select a service and upload files

2. Get engineer feedback and quote

3. Manufacturing Start

4. Parts are delivered

Why Choose Us?

Taking full advantage of any on demand manufacturing services means choosing those who not only own powerful manufacturing capabilities, but also produce complex end-use parts in a fast, efficient, and smart way. Capable Machining meets these requirements.

Industries Served

With the superior quality and reliable functionality of our prototypes, molds, and finished products, they see extended use in various industries as they become integral components for many businesses.

Read Latest Blogs

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.

Precision Door Lock Multi-Axis Machining Process and Fixture Design

Precision door locks present numerous challenges in traditional CNC machining due to their complex and diverse structures, unique contour profiles,…

Research on CNC Milling Tool Technology in Mold Manufacturing

In modern manufacturing, the quality and precision of mold production directly impact product performance and appearance. As a critical process…

Five-Axis CNC Machine Tool Error Compensation for High-Precision Machining

Five-axis CNC machine tools, as key equipment for machining complex curved surfaces, feature three linear axes and two rotary axes….

Exploring Methods to Enhance Tooling Precision in CNC Machining

As modern manufacturing evolves toward intelligent and high-end development, precision machining demands significantly higher tool accuracy.

Research on the Error Control Method for Five-Axis CNC Machine Tool Machining based on Digital Twin

Five-axis CNC machines are widely used in high-precision complex surface machining, characterized by multiple interconnected axes and frequent tool orientation…

Practical Exploration of Automation Technology in Machining Manufacturing

The machinery manufacturing industry serves as a pillar of the national economy, with its development level directly impacting the nation’s…