China CNC Milling » Blog » Expert Tungsten Alloy Manufacturing Insights You Won’t Want to Miss

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

On any engineer’s list of “nightmare materials,” tungsten alloys rank high. Their high density and extreme hardness make machining a grueling battle at every stage.

How can we achieve an efficient leap from raw blank to precision part with this tough nut to crack?

Hold on—here comes the million-dollar “game-changing guide”! This article dissects the process from the very start of blank preparation, comparing the pros and cons of powder metallurgy versus 3D printing.

It delves into core techniques for cutting, grinding, and wire EDM, and proudly introduces the “cutting-edge tech” that will make your work twice as effective with half the effort—Powder Extrusion Printing (PEP). This provides a solid foundation for your design and manufacturing endeavors.

Introduction

Tungsten alloys, primarily composed of tungsten (typically 85%–99% by weight) with additions of nickel, iron, copper, cobalt, molybdenum, and chromium, play an indispensable role in high-tech sectors like nuclear, military, and medical industries.

Their exceptional properties—including extremely high density (16.5–19.0 g/cm³), high melting point, and outstanding mechanical strength, tungsten alloys play an indispensable role in multiple high-tech fields such as nuclear industry, military applications, and medical technology.

In the medical field, tungsten alloys are used to manufacture critical components for radiotherapy equipment. Leveraging their high density, these alloys precisely block and shape radiation beams, making them the primary material for collimators and radiation shielding.

These exceptional properties also present significant challenges in the processing and manufacturing of tungsten alloys.

This paper aims to systematically and thoroughly explore the blank preparation processes and common machining methods for tungsten alloy components, providing valuable references for their precision manufacturing.

Preparation Processes for Tungsten Alloy Component Blanks

Powder Metallurgy Technology

Due to their high density, high melting point, and high hardness, tungsten alloys cannot be manufactured using conventional alloy smelting processes.

> Powder Metallurgy: Key Steps

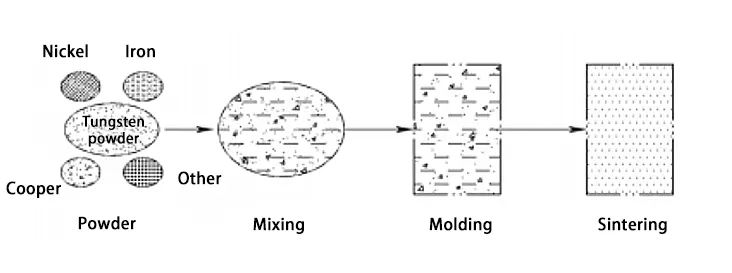

Powder metallurgy, a traditional and widely applied method for preparing tungsten alloy blanks, involves key steps as shown in Figure 1: tungsten powder preparation, mixing, forming, and sintering.

During tungsten powder preparation, processes like hydrogen reduction or ammonium paratungstate reduction are commonly employed to ensure powder purity.

Simultaneously, the oxygen content, particle size, and shape of tungsten powder significantly impact the final properties and quality of the alloy, necessitating strict control.

Excessive oxygen content degrades alloy performance, while particle size and shape affect the effectiveness of subsequent mixing and forming processes.

For instance, uniformly sized tungsten powder facilitates more even mixing with other metal powders during blending, ensuring consistent alloy composition.

During mixing, precise blending methods like mechanical stirring or ball milling are employed to ensure uniform particle size and accurate proportions of various metal powders.

Forming methods include cold isostatic pressing, die pressing, powder extrusion, and powder injection molding, enabling the production of complex-shaped components.

> Sintering: Achieving Density and Strength

Sintering is critical for achieving the required density, strength, and other properties in tungsten alloys. A two-step sintering method is widely adopted:

During the pre-sintering stage, temperatures are typically controlled between 1000–1200°C. Within this range, low-melting-point metals like copper and iron reach liquid states, enabling solid-phase diffusion with surrounding tungsten powder particles.

This process fixes the positions of tungsten alloy powder particles and ensures uniform filling, achieving blank shaping.

This is immediately followed by the high-temperature sintering stage, where solid-phase and liquid-phase reactions occur between powder particles, ultimately forming a dense tungsten alloy structure.

Control of sintering temperature and time plays a decisive role in product performance. If sintering time is too long, tungsten crystal size increases, affecting the alloy’s density and overall properties.

Excessive temperatures cause volatilization of low-melting-point metals like copper and iron, reducing alloy density and mechanical strength.

Sintering temperatures are typically maintained around 1400°C. Pre-sintering and high-temperature sintering are usually conducted under vacuum or inert gas conditions to minimize oxidation and volatilization of low-melting-point alloys.

A common process sequence is:

First, the formed tungsten powder blank is pre-sintered at 1200°C for 1 hour in a hydrogen atmosphere to impart initial strength and electrical conductivity.

Subsequently, electrical self-resistance sintering is performed, utilizing heat generated by the blank’s own resistance to further promote sintering.

Additive Manufacturing Processes

Traditional powder metallurgy methods can only produce blanks with relatively regular shapes. For complex-structured tungsten alloy parts, especially those with intricate cavities, the formed blanks require additional complex machining to ultimately meet part specifications.

Currently, there are no effective machining methods for forming complex enclosed internal cavities, which also limits the design possibilities for tungsten alloy parts.

Additive manufacturing technologies offer novel solutions for designing and producing tungsten alloy components.

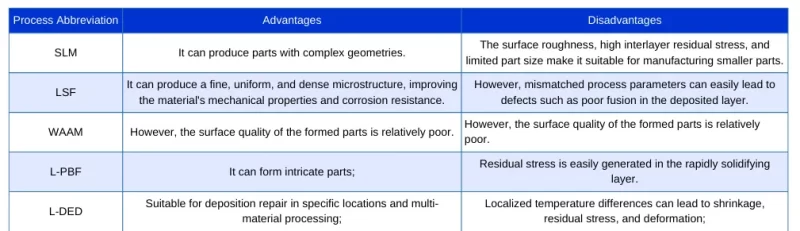

Commonly used metal additive manufacturing techniques include Selective Laser Melting (SLM), Laser Sintering (LSF), Wire Arc Additive Manufacturing (WAAM), Laser Powder Bed Fusion (L-PBF), and Laser Directed Energy Deposition (L-DED).

Table 1 compares the advantages and disadvantages of different additive manufacturing processes for producing tungsten alloy parts.

SLM can fabricate parts with complex geometries but suffers from issues such as surface roughness, high interlayer residual stresses, and dimensional limitations, making it suitable for small parts;

LSF yields fine, uniform, and dense microstructures, enhancing mechanical properties and corrosion resistance. However, mismatched process parameters may cause fusion defects in deposited layers.

WAAM is suitable for manufacturing large, monolithic aerospace structural components with high forming rates and high density. Nevertheless, the surface quality of formed parts is relatively poor.

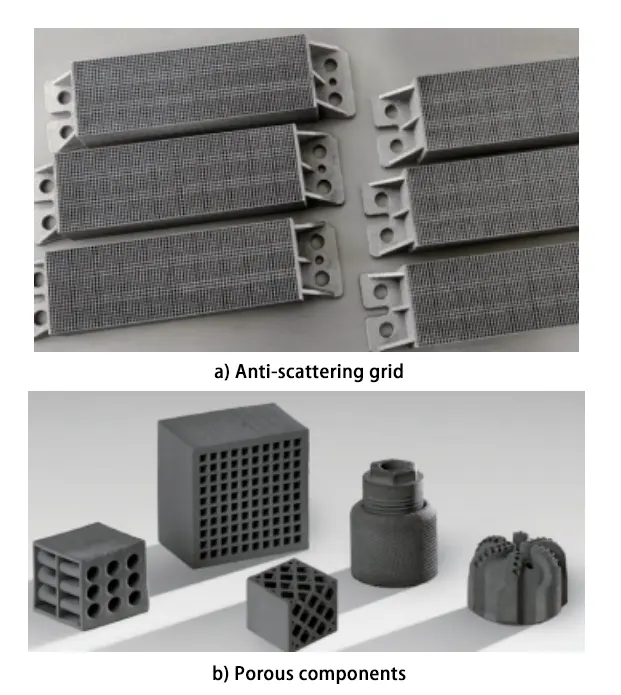

Typical tungsten alloy parts manufactured using additive manufacturing technologies are shown in Figure 2.

Compared to traditional powder metallurgy methods, additive manufacturing offers distinct advantages in producing complex-structured tungsten alloy parts.

It not only enables fabrication of components with intricate geometries and cavities to meet specialized design requirements but also facilitates layer-by-layer material deposition, improving material utilization and reducing costs.

Process Comparison and Selection

Powder metallurgy and additive manufacturing are currently the two primary methods for producing tungsten alloy blanks, each with distinct advantages and disadvantages in blank preparation.

Table 2 compares tungsten alloy blank preparation processes. Powder metallurgy is relatively more mature, yielding superior material density and excelling in stable batch production.

Additive manufacturing, a newer process developed in recent years with multiple derivative techniques, demonstrates advantages in producing structural components with complex cavities.

To pursue higher comprehensive performance, tungsten alloy components in cutting-edge fields such as aerospace, defense, nuclear industry, medical equipment, and electronics are trending toward increasingly complex structural features—including thin walls, curved surfaces, and porous structures—which traditional powder metallurgy methods struggle to achieve.

Directly using additive manufacturing to produce pure tungsten alloy parts with high relative density and no defects still faces technical challenges.

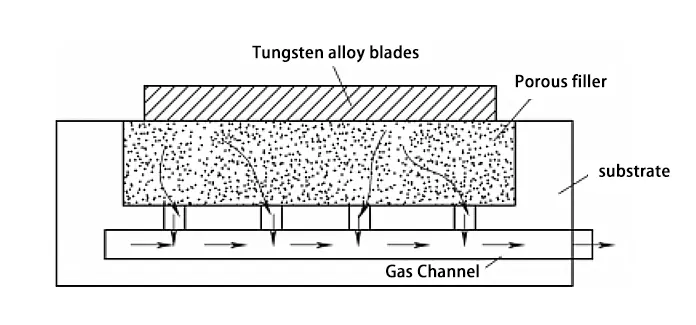

Powder Extrusion Printing (PEP), an indirect metal 3D printing technology combining “3D printing + powder metallurgy,” employs a binder-adapted tungsten alloy powder.

Components are first shaped using 3D printing equipment, then undergo post-processing through powder metallurgy’s debinding and sintering processes to ultimately yield structurally dense, high-performance parts.

This technology offers a novel solution to challenges in machining tungsten alloys and producing complex structures.

Its low-temperature forming and high-temperature sintering characteristics effectively address issues like deformation, cracking, and porosity commonly encountered in other 3D-printed tungsten alloy processes.

Machining of Tungsten Alloy Parts

The high density of tungsten alloys subjects cutting tools to immense cutting forces during machining. This demands tool materials with exceptional hardness and wear resistance, while tool design must also carefully consider the distribution and balance of cutting forces.

The high hardness of tungsten alloys (typically >40 HRC) significantly accelerates tool wear during cutting, impacting machining accuracy and tool life. Tool longevity and machining efficiency thus become critical considerations in this process.

Tungsten alloys exhibit relatively low thermal conductivity, making it difficult for heat generated during cutting to dissipate rapidly. The cutting edge operates under high temperatures, prone to thermal stress that accelerates tool deformation and wear.

Tungsten alloy chips form granular particles, complicating chip evacuation.

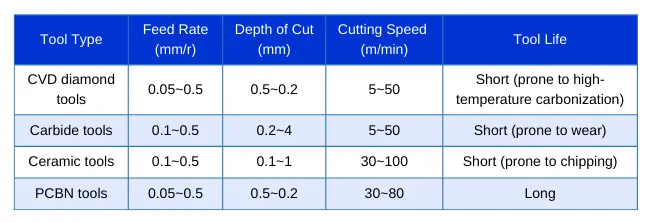

They readily accumulate in the cutting zone, forming chip buildup that compromises surface finish quality and may damage tools and machine tools. Table 3 compares cutting tools and process parameters for machining tungsten alloy parts.

In engineering practice, PCBN tools represent one of the optimal choices. Figure 3 illustrates a typical tungsten alloy part processed by machining.

Grinding of Tungsten Alloy Parts

Grinding, as a micro-cutting method, is suitable for machining high-hardness materials like tungsten alloys.

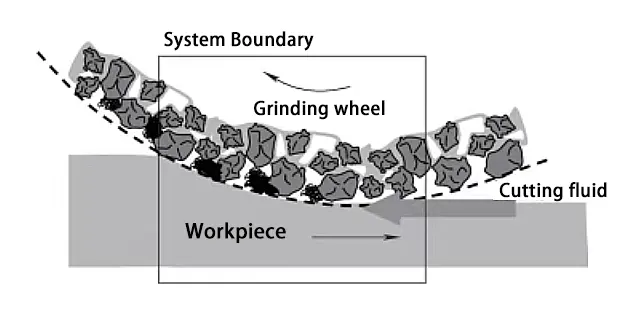

As shown in Figure 4, grinding wheels primarily consist of abrasive grains, pores, and a bonding agent in specific proportions. The abrasive grains feature blunt angles typically ranging from 90° to 120°.

During tungsten alloy grinding, the resulting grinding debris forms granular particles.The team easily evacuates these chips due to their relatively low viscosity and toughness, which also reduces the likelihood of clogging the abrasive wheel’s pores.

Therefore, they employ grinding wheels with larger pores for tungsten alloy processing to enhance grinding efficiency and machining quality.

Heat tends to accumulate in the grinding zone, potentially causing thermal burn damage.

The team applies high-pressure, high-flow forced cooling to promptly dissipate heat generated during grinding, minimizing thermal deformation and stress in the grinding area.

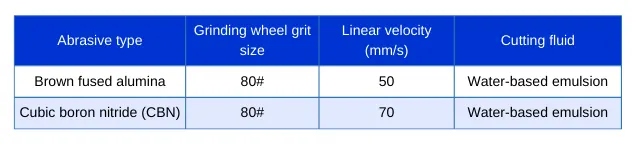

They typically select water-based emulsions as cutting fluids to ensure optimal cooling performance. Table 4 lists the grinding process parameters for tungsten alloy parts.

Figure 4. Schematic diagram of grinding with a grinding wheel

Pure tungsten or tungsten-nickel-copper alloy parts exhibit low magnetic properties. For thin-walled components, reliable clamping with traditional electromagnetic chucks is challenging.

The team can use vacuum suction fixtures for mounting. Figure 5 shows a vacuum-positioning fixture for tungsten alloy parts.

Wire-Cut EDM Machining of Tungsten Alloy Parts

Tungsten alloys exhibit high melting points and hardness. The team performs machining using high-hardness tools such as coated tools, PVD tools, and ceramic tools.

However, tool wear is significant, and features like pores, narrow slots, and irregular holes are difficult to machine with these conventional tools.

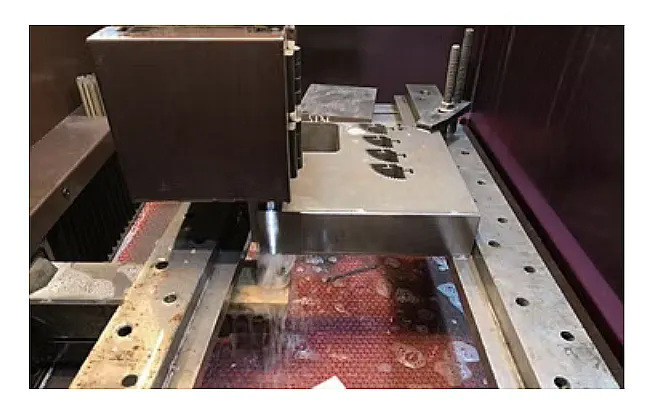

Electrical discharge wire cutting (EDM) is a specialized machining process. Its fundamental principle involves generating pulsed spark discharges between a continuously moving fine metal electrode wire (typically copper or molybdenum) and the workpiece.

The resulting temperatures, typically reaching 8000–12000°C, are sufficient to melt or even vaporize the surface layer of tungsten alloy, thereby achieving workpiece cutting.

The relative motion between the electrode wire and the workpiece enables the formation of the desired shape on the workpiece surface throughout the cutting process.

Figure 6 illustrates the use of wire cutting to process irregular holes in a tungsten alloy blank.

When machining tungsten alloy parts via wire cutting, high temperatures cause phase transformations in the cut surface, resulting in a metamorphic layer that loses the alloy’s characteristic properties.

The team employs a “cut-and-repair” method, progressively reducing the cutting depth and pulse power parameters to restore the metamorphic layer.

Conclusion

This paper investigates and summarizes the blank preparation, common machining methods, and processing challenges for precision tungsten alloy components.

Regarding blank preparation, powder metallurgy offers relatively mature processes, yielding superior material density and advantages in stable batch production.

Additive manufacturing, a newer process developed in recent years with diverse process routes, excels in producing structural components with complex cavities.

For machining, PCBN tools offer advantages by achieving high tool life and reducing the impact of tool wear on machining accuracy.

Grinding technology excels in processing regular surfaces, delivering superior surface quality. For hole and slot features, wire cutting achieves high machining efficiency.

The aforementioned blank preparation processes, along with machining, grinding, and wire-cutting methods, effectively enhance the manufacturing quality and production efficiency of precision tungsten alloy components, providing technological support for related industrial development.