Rotary two Color Mold Design

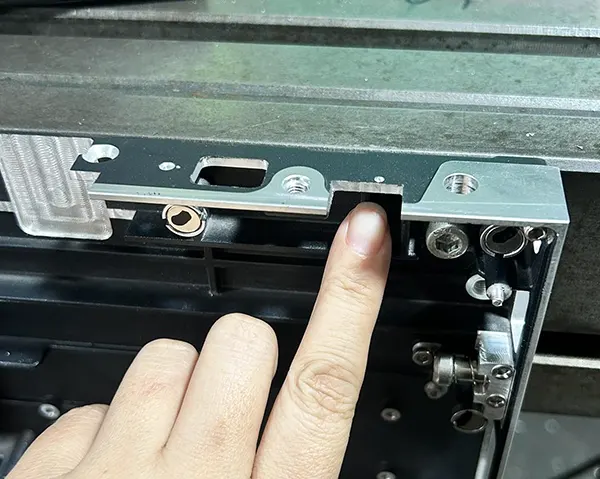

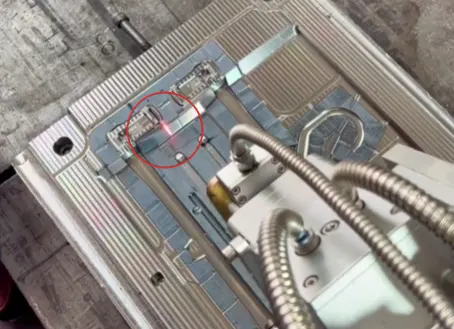

Ordinary injection molding machines can usually only produce plastic products of one color in the production and manufacturing of molds, not two-color injection. While two-color injection molding refers to the injection of two different materials into the same pair of…