China CNC Milling » Blog » What is Precision Injection Molding?

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Precision injection molding, strictly speaking, refers to an injection molding production method where the dimensional accuracy of plastic products manufactured via injection molding equipment can achieve tolerances below 0.01mm, typically ranging between 0.01mm and 0.001mm.

The concept of “precision injection molding” primarily distinguishes itself from “conventional injection molding.”

With the rapid advancement of polymer materials and microelectronics technology, coupled with the high integration of electronic circuits, industrial equipment components have progressively evolved toward high performance, high precision, lightweight design, miniaturization, and micro-miniaturization.

Consequently, precision plastic components—meeting stringent accuracy requirements while offering superior mechanical properties, strength, and dimensional stability—have gained widespread adoption across industries including machinery, electronics, instrumentation, communications, automotive, and aerospace.

They increasingly replace high-precision metal parts in specialized applications.

By definition, precision injection-molded plastic parts feature extremely narrow dimensional tolerances.

Within the plastic molding industry, it is widely accepted that parts with tolerances below 0.1mm—or with positive/negative dimensional variations under 0.1mm—qualify as precision molding.

Components achieving micron-level dimensional tolerances are classified as ultra-precision injection molding.

Compared to precision injection molding, parts produced by conventional injection molding typically have dimensional tolerances exceeding 0.1mm.

Their tolerance range is relatively broad, and as the part’s volume or weight increases, its dimensional tolerance also tends to widen.

It is worth noting that due to differences in material properties and processing methods, the precision of plastic parts cannot be equated with that of metal components.

The highest precision grade for plastic products is Grade 3, where dimensional tolerances can reach below 0.001mm.

In contrast, metal parts are categorized into fourteen size grades, with machining precision divided into nine grades.

Characteristics of Precision Injection Molding

1. High dimensional accuracy with tight tolerances, meaning precise dimensional limits.

Dimensional deviations in precision plastic parts fall within 0.03mm, sometimes even reaching micrometer levels, requiring inspection tools like projectors.

2. High repeatability accuracy. This is primarily reflected in minimal weight deviation, typically below 0.7%.

3. High-quality mold materials with sufficient rigidity, ensuring high dimensional accuracy and surface finish of cavities, as well as precise positioning between mold plates.

4. Utilization of precision injection molding equipment.

5.Precision injection molding process . Precise control of mold temperature, cycle time, part weight, and molding production parameters.

6.Materials suitable for precision injection molding . PPS, PPA, LCP, PC, PMMA, PA, POM, PBT, and engineering plastics reinforced with glass or carbon fibers.

Factors Affecting Precision Injection Molding

To produce precision plastic parts through injection molding, five critical factors are indispensable: material selection, mold design and machining, injection molding process, the technical proficiency of molding personnel, and precision injection molding machines.

The precision of precision plastic parts encompasses dimensional accuracy, geometric accuracy, and surface finish, corresponding to dimensional tolerances, geometric tolerances, and surface roughness respectively.

Among these, dimensional accuracy is a critical indicator of both manufacturing quality and serviceability for plastic components. Key factors affecting dimensional accuracy include:

Utilizing Plastics with High Dimensional

StabilityShrinkage characteristics are inherent to plastics and significantly impact dimensional stability and precision.

These characteristics encompass the combined effects of thermal shrinkage, elastic recovery, plastic deformation, post-shrinkage, and aging shrinkage.

They manifest as changes in linear shrinkage rate and volumetric shrinkage rate during molding and use, influenced by environmental factors, and are commonly expressed through shrinkage property values.

Mold Design and Machining Precision

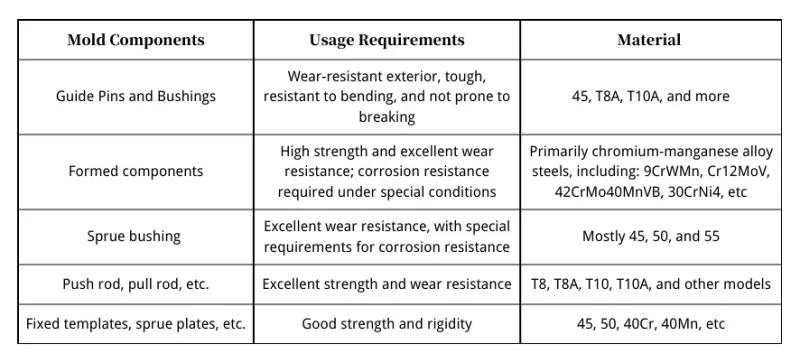

1. Materials for Precision Molds

Select alloy steels with high mechanical strength. Materials for cavities and runners must undergo rigorous heat treatment.

Prioritize materials with high hardness (molding components should reach approximately HRC 52), excellent wear resistance, and strong corrosion resistance.

2. Machinability and Rigidity

In mold structural design, avoid excessive cavity counts. Thicken base plates, support plates, and cavity walls to prevent severe elastic deformation under high temperature and pressure. Refer to the table below for mold component usage conditions:

3. Demolding Properties of the Product

Molds should utilize as few cavities as possible, feature short and compact runners, and achieve a higher surface finish than standard molds to facilitate demolding.

4. Part Precision

This primarily depends on cavity dimensional accuracy, cavity positioning accuracy, and parting line precision.

Evaluation criteria include whether the part design facilitates machining, whether the mold gate ensures good filling performance, and whether the cooling system provides uniform mold cooling.

Generally, dimensional tolerances for precision injection molds should be controlled below one-third of the part’s dimensional tolerance.

Temperature, Humidity, and Amplitude

The ability of molded parts to maintain their shape without deformation when subjected to external forces or in environments with temperature fluctuations should be excellent.

Injection Molding Equipment

Precision injection molding machines are injection units equipped with closed-loop control for the injection process.

Typically, both injection pressure and injection speed are managed through closed-loop control.

Closed-loop control, also known as feedback control, refers to a system where sensors monitor the output signals of the control system.

These signals are transmitted back to the controller, which processes them to ensure the output aligns with the system’s target values.

This minimizes deviation between the actual output and the desired output, making the output signal as close as possible to the expected value.

Simply put, closed-loop control is an automatic adjustment mechanism that brings the output closer to the desired value.

By employing injection closed-loop control, injection molding machines significantly enhance the repeatability and stability of the injection molding process.

This reduces dimensional fluctuations in the molded parts, thereby improving their dimensional accuracy and dimensional stability.

To achieve closed-loop control in injection molding machines, hydraulic injection molding machines must utilize servo valves to implement closed-loop control of both pressure and flow within the hydraulic system.

Beyond servo valves, ultra-precision injection molding machines incorporate servo control boards.

These boards, integrated with computer control systems, further enhance the repeatability of hydraulic output pressure and flow, enabling ultra-precise injection molding.

Compared to hydraulic machines, all-electric injection molding machines hold significant advantages in achieving fully closed-loop injection control.

The computer motion controller of an all-electric injection molding machine drives servo motors.

Through a logic controller, it performs logical operations on sensor feedback signals, achieving full closed-loop control over injection actions including injection, plasticization, mold opening/closing, and ejector pin movements.

Position control can reach 0.01mm, resulting in higher dimensional accuracy of molded parts and significantly improved machine stability and repeatability.

Utilizing Precision Molding Techniques

Employing multi-stage injection molding and precisely controlling mold temperature

Shrinkage Issues in Precision Injection Molding

Precision injection-molded parts not only involve concepts of dimensional tolerances, geometric accuracy, and surface finish, but also require repeatability precision—ensuring stable accuracy over days, months, years, and under varying environmental conditions.

These precision requirements depend not only on material properties and mold accuracy but also on molding shrinkage, which significantly impacts part dimensions.

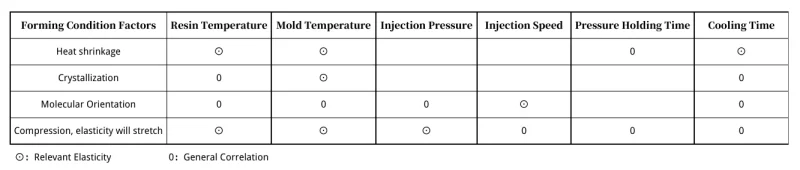

Four primary factors influence part shrinkage.

Thermal Shrinkage

Thermal shrinkage stems from the inherent thermophysical properties of both the molding material and the mold material.

Higher mold temperatures elevate the product’s temperature, increasing the actual shrinkage rate.

Therefore, mold temperatures for precision injection should not be excessively high.

Phase Transition Shrinkage

This occurs during the orientation process of crystalline resins, where polymer crystallization reduces specific volume.

Higher mold temperatures increase crystallinity and shrinkage rate.

Conversely, enhanced crystallinity boosts product density, reduces linear expansion coefficient, and lowers shrinkage rate.

The actual shrinkage rate results from the combined effects of these factors.

Orientation Shrinkage

Forced stretching of molecular chains along the flow direction causes macromolecules to tend toward recoil and recovery during cooling, resulting in shrinkage along the orientation axis.

Molecular orientation depends on injection pressure, injection speed, resin temperature, mold temperature, etc., but injection speed is the primary factor.

Compression Shrinkage and Elastic Recovery

Most plastics exhibit compressibility, meaning their specific volume changes significantly under high pressure.

At typical temperatures, increasing pressure during molding reduces specific volume, increases density, decreases expansion coefficient, and significantly lowers shrinkage rate. Corresponding to compressibility, molding materials exhibit elastic recovery, mitigating product shrinkage.

Factors influencing molding shrinkage relate to molding conditions and operational parameters.

Correlation between molding shrinkage and conditions:

Definition of Precision Injection Molding Machines

Precision injection molding machines refer to molding equipment suitable for producing precision plastic products.

How should one measure or evaluate a precision injection molding machine?

Typically, precision injection molding machines are assessed by two metrics: the repeatability deviation of product dimensions and the repeatability deviation of product weight.

The former is difficult to compare due to variations in product size and thickness. The latter represents the machine’s overall capability.

Standard injection molding machines typically exhibit weight repeatability errors around 1%, while higher-quality machines can achieve 0.8%.

Machines below 0.5% are classified as precision machines, and those below 0.3% are considered ultra-precision machines.

As mentioned earlier, precision injection molding machines require dimensional accuracy generally within 0.01 to 0.001 mm.

Many precision molding applications also demand high injection pressure and high injection speed.

The clamping system must possess sufficient rigidity and clamping precision.

Clamping precision refers to the uniformity, adjustability, stability, and high repeatability of clamping force, along with high accuracy in mold opening/closing positions.

Precise control over pressure, flow rate, temperature, and metering must be achieved to corresponding tolerances.

Multi-stage injection is employed to ensure process reproducibility and consistent part accuracy.

Requirements for Injection Molding Machines in Precision Injection Molding

Technical Parameter Characteristics

1. Injection Pressure

Conventional injection molding machine: 147–177 MPa Precision injection molding machine: 216–243 MPa Ultra-high pressure injection molding machine: Above 243 MPa, typically ranging from 243 to 392 MPa.

The advantages of achieving high-pressure molding with precision injection molding machines include:

①. Enhanced precision and quality of precision parts. Injection pressure most significantly impacts part shrinkage during molding.

At 392 MPa injection pressure, part shrinkage approaches zero.

At this point, part precision is solely influenced by mold control or environmental factors.

Testing confirms: increasing injection pressure from 98 to 392 MPa boosts part mechanical strength by 3–33%.

②. Reducing wall thickness and increasing molded length for precision parts.

Using PC as an example: a standard machine at 177 MPa can mold parts with 0.8 mm wall thickness, while a precision machine at 392 MPa can mold parts with wall thicknesses exceeding 0.45 mm.

Ultra-high-pressure injection machines can produce parts with significantly higher flow length ratios.

③. Increasing injection pressure fully leverages the effectiveness of injection speed.

To achieve the rated injection speed, two approaches exist:

- Raising the system’s maximum injection pressure;

Modifying injection device or system parameters, including screw parameters.

2. Precision Injection Machines Demand High Injection Speeds

Precision hydraulic injection molding machines require injection speeds exceeding 200 mm/s, while all-electric injection molding machines can reach speeds above 300 mm/s.

Characteristics of Precision Injection Machines in Control Aspects

1. High repeatability precision requirements for injection molding parameters necessitate multi-stage injection reaction control:

- Multi-stage position control;

- Multi-stage speed control;

- Multi-stage holding pressure control;

- Multi-stage back pressure control;

- Multi-stage screw speed control.

Displacement sensors must achieve a minimum accuracy of 0.1mm to strictly control the metering stroke, injection stroke, and thickness of the residual material pad (injection monitoring point).

This ensures precise injection volume each time and enhances product molding accuracy.

2. Barrel and nozzle temperature control must be precise.

The temperature control system should exhibit minimal overshoot during heating and minimal temperature fluctuations.

Precision injection molding employs PID (Proportional-Integral-Derivative) temperature control, achieving temperature accuracy within ±1°C.

Ultra-precision injection molding machines attain temperature control precision of ±0.1°C, with temperature deviation stably maintained within ±0.2°C.

3. Hydraulic oil temperature must be regulated.

Fluctuations in oil temperature cause variations in injection pressure. A cooling system is essential to maintain oil temperature between 50–55°C.

4. Mold temperature control requirements.

Mold temperature significantly impacts post-molding thermal shrinkage, affecting part surface quality, crystallinity, and mechanical properties.

Assuming identical cooling times, parts molded at lower cavity temperatures exhibit greater thickness dimensions than those molded at higher temperatures.

Hydraulic System of Precision Injection Molding Machines

◊ Proportional Valve Control for Injection Molding Hydraulic Systems

The oil circuit system requires the use of proportional pressure valves, proportional flow valves, or closed-loop variable pump systems.

The hydraulic system of injection molding machines must employ proportional pressure valves and proportional flow valves to achieve different working pressures and flow rates.

Whether in fixed-displacement pump hydraulic systems or variable-displacement pump hydraulic systems, proportional valves are present to control the working pressure and flow rate output by the oil pump, enabling proportional linear adjustment.

◊ Necessity of Separating Clamping and Injection Circuits in Direct-Pressure Injection Molding Machines

In direct-pressure clamping mechanisms, separate the clamping circuit from the injection circuit.

This requirement applies specifically to direct-pressure injection molding machines.

These machines initiate melt injection to fill the mold cavity the instant high pressure is applied during clamping.

Simultaneously, hydraulic fluid must fill the clamping cylinder to establish high clamping pressure.

Otherwise, the center plate may retract due to filling pressure and mold expansion force, which is unacceptable.

This necessitates separating the clamping and injection circuits.

Failure to do so risks pump overload from simultaneous filling of both cylinders, compromising injection speed and system stability.

◊ Hydraulic System Responsiveness Requirements for Precision Injection Molding Machines

Precision injection molding machines demand high-speed operation, emphasizing hydraulic system responsiveness.

Most precision molding occurs under high injection pressure and velocity conditions (e.g., connectors or buttons), with extremely short filling times typically lasting only fractions of a second.

This demands high system responsiveness; otherwise, response lag will cause significant deviation between output signals and input requirements.

This complicates process tuning and directly impacts dimensional or weight stability during production.

The high responsiveness of an injection molding machine depends on the controller’s scanning time, the oil pump’s response time, and the hydraulic valve’s response time.

Hydraulic systems equipped with servo valves offer significant advantages in both responsiveness and repeatability.

Variable-displacement pump injection molding machines achieve high responsiveness and repeatability because the pump’s pressure and flow output are adjusted by altering the swashplate angle.

The pump’s repeatability can reach below 0.2%.

◊ Integrated Electromechanical–Hydraulic Control Architecture in Precision Injection Molding Machines

The hydraulic system of precision injection molding machines must fully embody integrated electromechanical-hydraulic-instrumentation engineering.

Modern injection molding machines universally employ fully computerized control systems with progressively enhanced functionality.

These systems incorporate intelligent features such as human-machine interaction, fault self-diagnosis, molding status monitoring, and SPC quality monitoring.

The hydraulic system serves as the power source for all machine operations, while the controller functions as the central management hub.

Various gauges provide auxiliary monitoring of machine operating conditions.

In essence, the injection molding machine is an intelligent entity that organically integrates mechanical, electrical, hydraulic, and instrumentation systems.

Structural Characteristics of Precision Injection Molding Machines

1. Due to the high injection pressure of precision injection machines, the clamping system requires high rigidity.

The parallelism between the moving and fixed platen must be controlled within 0.08–0.10 mm.

2. Protection for low-pressure molds and precise control of clamping force are essential.

Clamping force directly affects mold deformation, ultimately impacting part dimensional tolerances.

3. Mold opening and closing speeds must be fast, typically around 60 mm/s.

4. Plasticizing components—including the screw, screw head, anti-reverse ring, and barrel—must be designed for high plasticizing capacity, excellent homogenization, and high injection efficiency.

The screw drive torque must be substantial and capable of stepless speed variation.

Performance of Injection Molding Machines in Achieving Precision Injection Molding

As previously mentioned, injection-molded products have found applications across diverse fields, widely replacing high-precision metal components.

Consequently, stringent requirements have been imposed on the dimensional accuracy, mass precision, surface quality, and mechanical properties of injection-molded parts.

Simultaneously, higher demands are placed on process factors influencing the quality of injection-molded products.

The ideal state of product control for injection molding machines is to directly control variables affecting product dimensions, mass, surface quality, and mechanical properties through reactive control based on response signals.

However, currently, the direct measurement and conversion of these non-electrical quantities into electrical signals remains unresolved.

Therefore, solutions must rely on controlling the machine’s adjustable variables that influence the aforementioned product qualities, primarily:

1. Screw barrel section temperatures (non-periodic signals), typically requiring at least 4 heating zones;

2. Hydraulic oil temperature (non-periodic signal), detected using conventional thermocouples;

3. Screw pre-plastication displacement, detected by displacement encoders as periodic signals to derive velocity signals;

4. Injection system pressure, measured by strain gauges mounted on the injection cylinder to detect periodic signals for injection pressure, holding pressure, and back pressure signals;

5. Screw rotational speed, monitored by speed sensors to maintain constant back pressure;

6. Screw retraction stop position, used for measuring injection volume, detected by an electronic scale;

7. Injection pressure with at least 4-level setpoint curves and feedback signal detection for reaction control;

8. Injection speed with at least 4-level setpoint curves and feedback signal detection, converting displacement variables into speed feedback for reaction control.

Conclusion

Precision injection molding demands stringent control over materials, mold design, equipment configuration, and process parameters.

Achieving dimensional accuracy at the micrometer level requires high-stability materials, ultra-precise molds, advanced closed-loop injection molding equipment, and refined molding techniques that minimize shrinkage and deformation.

Precision injection molding machines—featuring high pressure, high injection speed, fast system responsiveness, and intelligent control—play a decisive role in ensuring repeatability and stability.

As industries push toward miniaturization and high performance, precision injection molding will continue to be a critical technology enabling the production of reliable, high-accuracy plastic components across an expanding range of applications.