China CNC Milling » Blog » Titanium Alloys with Unusual Properties are Used in the Aerospace

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

With the accelerated pace of human space exploration, the requirements for space vehicles are becoming higher and higher, increasing the demand for advanced materials such as titanium.

In addition to relying on optimized structural design, space vehicles operate under extreme conditions such as ultra-high temperature, ultra-low temperature, high vacuum, high stress, and strong corrosion.

They also depend on the excellent properties and functions of materials.

For aerospace materials, lightweight and high strength, high temperature, low temperature and corrosion resistance are the main criteria for the selection of aerospace products.

Titanium Alloys Property

The density of titanium is 4.5 g/cm3, which is only 56% of that of steel, meeting the demand for lightweight materials for aerospace products.

The strength of titanium alloy is 500 ~ 1,400 MPa, much higher than Al, Mg alloy.

Titanium alloy has superior performance at both high and low temperatures.

It can work long-term at 550 °C and as low as minus 250 °C while maintaining its properties.

Because of these qualities, titanium alloy is known as the “cosmic metal” or “space metal.”

It is widely used in aerospace products for this reason.

Aerospace products have specific material requirements.

As a result, titanium alloys have developed in different directions within the aerospace field.

These include high-toughness titanium alloys, high-temperature titanium alloys, low-temperature titanium alloys, casting titanium alloys, and powder titanium alloys.

High Toughness Titanium Alloy

In the 1970s, the United States successfully developed the α + β two-phase high-strength and high-toughness titanium alloy Ti62222S.

This alloy has good strength and plasticity.

Its room temperature breaking strength exceeds 1,300 MPa, and its yield strength exceeds 1,200 MPa.

The high strength and high toughness titanium alloy Ti62222S not only has good room temperature performance, but also has good high temperature performance.

When the working temperature is up to 500 °C, the fracture strength and yield strength of the high strength and high toughness titanium alloy Ti62222S are still above 800 MPa.

In addition, Ti62222S has high fracture toughness and damage tolerance. Its fatigue crack extension rate is comparable to that of Ti6Al4V.

It also has a modulus of elasticity and superplastic forming capability superior to Ti6Al4V.

These qualities make Ti62222S a good substitute for Ti6Al4V.

The excellent mechanical properties of high strength and high toughness titanium alloy Ti62222S make it widely used in × × prototype and F22 fighter aircraft and various missiles.

High Temperature Titanium Alloy

The research and development of ultrasonic cruise bombs, hypersonic cruise bombs, reusable carriers, and suborbital reusable trans-atmospheric vehicles demand titanium alloys that can perform at high temperatures—sometimes even up to 650 °C. T

herefore, titanium alloys must have excellent temperature resistance.

High-temperature titanium alloy research is extremely active and highly important. However, the development process is also extremely difficult.

This is mainly because high-temperature titanium alloys need to combine several properties.

They must have good room temperature performance, high-temperature strength, creep resistance, thermal stability, fatigue resistance, and fracture toughness.

These performance requirements often conflict with each other, as they depend on different and sometimes contradictory material compositions and microstructures.

The first international high-temperature titanium alloy is the United States in 1954 developed Ti6Al4V alloy, can be used at 300 ~ 350 ℃.

Ti6Al4V alloy has both α + β two-phase characteristics.

It can be used as a high-temperature alloy and as a structural alloy in aerospace applications.

Examples include the “Apollo” spacecraft, “Cosmonauts” missiles, and “Prowler” satellites.

This alloy has been widely used in the aerospace field.

However, Ti6Al4V alloy also has some shortcomings, mainly heat resistance is not good enough, hardenability is not ideal, cold workability is poor, the preparation process is complex.

To maximize the strengthening effect of aluminum solid solution heat treatment, titanium alloys also include elements such as Sn, Zr, Mo, and Si.

This has led to the development of alloys for different temperature ranges:

IMI834, Ti1100, BT36, and other alloys for use between 550 and 600 °C.

IMI679 and Ti6242 alloys for use up to 450 °C,

IMI685 and Ti6242S alloys for use up to 500 °C,

In addition to Ti6Al4V alloy, Ti6242S, Ti1100 and other alloys are more mature.

The first generation of partially reusable ultrahigh-speed manned vehicles in the United States was the space shuttle.

It used the titanium alloy Ti1100 as part of its thermal protection system. Specifically, Ti1100 was used for heat-resistant tiles.

The second generation of the space shuttle, or the National Aero-Space Plane (NASP), also used rapidly solidified titanium alloys in its thermal protection system.

Similarly, the sub-orbital, single-stage-to-orbit rocket launcher X-33 continued to use the titanium alloy Ti1100 for its heat-resistant tiles.

The suborbital single-stage-to-orbit rocket launcher X-33 also uses the titanium alloy Ti1100 for its large-area heat protection system on the leeward side of the fuselage.

The fuselage of the British space plane HOTOL is also partly made of titanium alloy, while the German Sanger space plane uses a multi-layer walled titanium-based structure for its fuselage.

Aerospace vehicles and their thrust systems require high-temperature titanium alloys.

In recent years, rapid solidification and powder metallurgy technologies have been increasingly used to develop titanium alloys.

These methods mark a key direction in the development of high-temperature titanium alloys.

Using these advanced technologies, McDonnell Douglas in the United States has developed a high-purity, high-density titanium alloy.

This alloy maintains a strength at 760 °C that is equivalent to the strength of conventional titanium alloys at room temperature.

Low Temperature Titanium Alloy

Titanium alloys have good mechanical properties at low temperatures and are widely used in aerospace applications.

As the temperature decreases, the strength of titanium alloy increases greatly. However, elongation, impact toughness, and fracture toughness decrease.

This decline is especially significant below 77 K.

With the rapid development of space technology, titanium alloys are increasingly used in low and very low temperature environments.

Therefore, the development of low-temperature titanium alloys is extremely important.

Researchers have found that reducing the content of interstitial elements such as hydrogen (H), oxygen (O), nitrogen (N), and aluminum (Al) improves the low-temperature performance of titanium alloys.

This allows the alloys to be used for extended periods at temperatures as low as 20 K.

Commonly used low-temperature titanium alloys are designed for both low and very low temperature applications.

The commonly used low-temperature titanium alloys are TC4ELI and TA7ELI ultra-low-gap alloys, which are obtained by reducing the content of interstitial elements such as H, O, etc.

TC4ELI alloys are used for the manufacture of low-temperature and high-pressure cylinders and cryogenic tubes, and TC4ELI alloys are used for the manufacture of liquid hydrogen tanks and other components.

However, the poor processing and cold forming properties of TC4ELI and TA7ELI ultra-low-gap alloys have seriously limited their use.

To address this issue, Japan developed a new low-temperature structural titanium alloy called LT700 (Ti3Al5Sn1Mo0.2Si).

At low temperatures, the LT700 alloy exhibits high yield strength and good plasticity, comparable to the Ti-5Al-2.5Sn ELI alloy.

In addition, LT700 has better fracture toughness and a more favorable match between fracture toughness and yield strength. Its high peripheral fatigue strength surpasses that of the TA7 ELI alloy.

When the temperature is T = 77 K and the number of cycles N = 10⁵, the maximum fatigue strength of LT700 reaches up to 1,300 MPa.

In contrast, the Ti-5Al-2.5Sn ELI alloy achieves only 1,100 MPa under the same conditions.

Due to these superior properties, LT700 has been used in the production of liquid hydrogen turbopumps.

In addition, titanium alloy BT20 is also used to manufacture the outer shell of missiles and fuel tank shells.

To meet the demands of the new generation of launch vehicles, which require large-volume cryogenic liquid oxygen and liquid hydrogen high-pressure cylinders, we have developed large-size TC4ELI titanium alloy forging cakes.

Specifically, we have successfully produced TC4ELI and TA7ELI titanium alloy forging cakes measuring 300 mm by 120 mm.

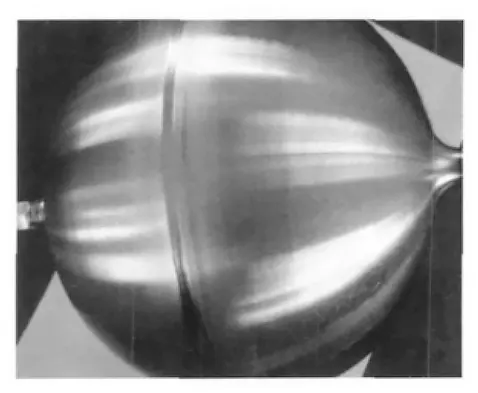

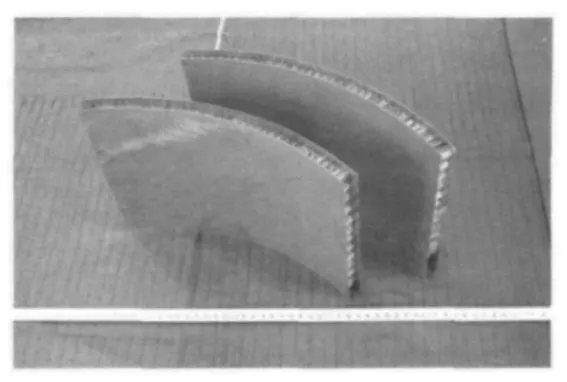

In response to the demand for large-size thin-walled titanium alloy components for aerospace vehicles, the Institute of Aerospace Materials and Processes has conducted research on spinning and forming technology.

This research focuses specifically on large-size thin-walled TC4 titanium alloy.

As a result, they successfully spun TC4 titanium alloy hemispherical samples with a diameter of 420 mm.

They also produced curvilinear TC4 titanium alloy samples with a diameter of 580 mm.

These samples were used in the development of titanium alloy cassette tank test pieces.

Cast Titanium Alloy

Advantages and Challenges of Cast Titanium Alloys

Cast titanium alloy has low density and high strength at room and medium temperatures.

It also offers good corrosion resistance and casting process performance.

Additionally, it has good impact toughness and weldability.

However, titanium has a melting point of 1,668 °C and very active chemical properties. In the molten state, it easily reacts with air and casting materials.

This makes it very susceptible to contamination by impurities such as hydrogen (H), oxygen (O), and nitrogen (N), which causes metal embrittlement.

Historical Development and Commercialization of Titanium Alloy Casting

This brings difficulties to the casting of titanium alloys, resulting in the development of casting process of titanium alloys lag far behind the pressure processing technology.

Until the early 1950s, the United States began to test the casting of titanium alloys, and in 1965 industrialized production.

In the casting of titanium alloys in the early stages of development, selected Ti6Al4V and other commonly used deformation of titanium alloys for testing.

A large number of test results show that Ti6Al4V alloy can be used as a good cast titanium alloy.

At present, Ti6Al4V alloy has become the main casting titanium alloy in Europe, America, Japan and other countries.

The most important cast titanium alloy in Russia is Ti5Al alloy.

Progress in Titanium Alloy Casting for Aerospace Applications

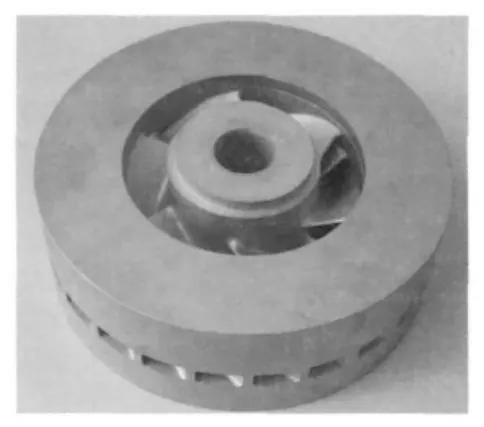

Now, titanium castings have progressed from static components to rotating components.

For example, the United States Aerojet company produces rocket engine impellers for cryogenic turbopumps using titanium casting.

Powdered Titanium Alloy

The Challenge of Titanium Alloy’s High Cost

Although titanium alloy has excellent performance, including high specific strength and strong corrosion resistance, its relatively high price limits its widespread use.

At present, a lot of research is focused on low-cost manufacturing technology for titanium alloy and its components.

One important area of this research is powder metallurgy technology for titanium alloys.

Progress in Powder Metallurgy for Aerospace Applications

After many years of research, titanium alloy powder metallurgy near-net-shape technology has made great progress.

This is especially true in the aerospace field, where its commercial applications have been realized.

In the United States, several companies have mastered high-performance powder metallurgy technology and its related production and applications.

Titanium Alloy Powder Metallurgy in Missile and Aerospace Components

These companies include Bodycote, ADMA, and Pratt & Whitney.

High-performance powder titanium alloy technology has been applied in the manufacturing of various missile weapons that incorporate titanium alloy parts.

For example, Sidewinder missiles use powder titanium alloy cowls.

The F107 cruise missile engine features powder titanium alloy impellers.

Stinger anti-aircraft missiles also use powder titanium alloy impellers.

Additionally, Stinger missiles are equipped with powdered titanium alloy warheads and new titanium-tungsten composite warheads.

Russia has strong capabilities in developing powder metallurgy products.

It was the first in the world to develop a complete complex-shaped powder titanium alloy hydrogen pump turbine.

Advancements in Low-Temperature and High-Temperature Powder Titanium Alloys

This technology has been applied in RD-0120 and other types of hydrogen and oxygen engines. Titanium alloy powder metallurgy is also used in other applications.

We have also manufactured the entire VT5-1 kt alloy fuel supply guide vane device for hydrogen-oxygen engines using titanium alloy powder metallurgy technology.

Its performance and reliability are far better than traditional products.

At present, powdered titanium alloy technology has begun to be applied in the development of various product models.

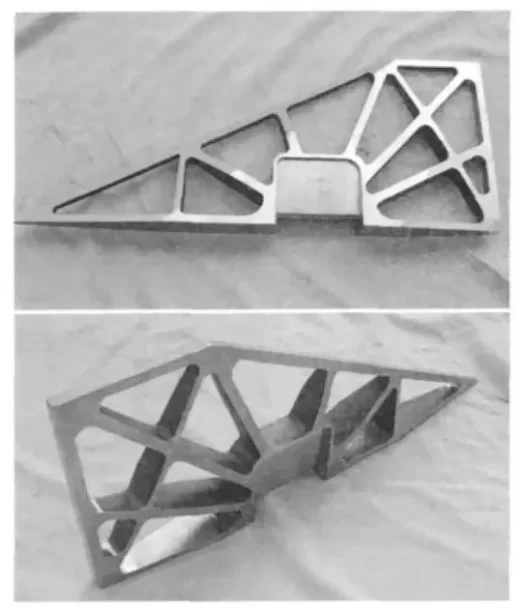

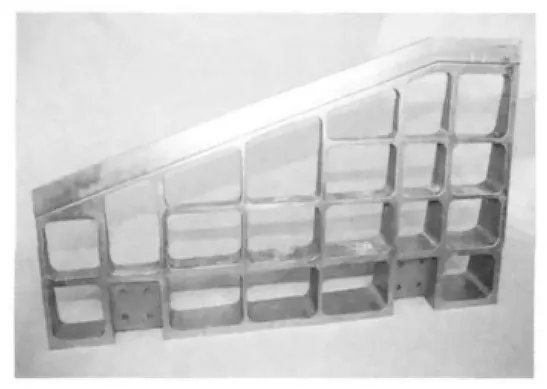

These include titanium alloy rudder core skeletons, large-size horizontal wing skeletons, missile hulls, and impellers.

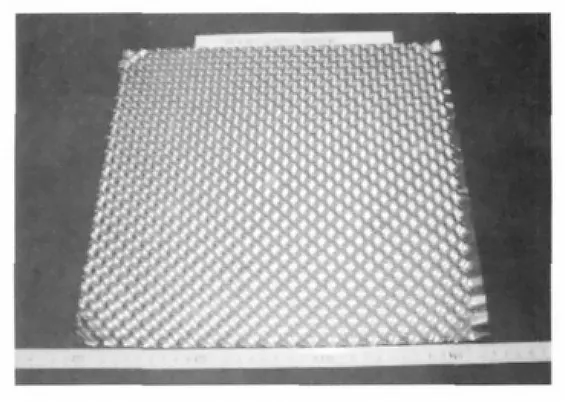

The developed powder TA15 large-size horizontal wing skeleton (Figure 3), has passed the ground static load test.

The powder TC11 titanium alloy has been used to make a high-temperature-resistant monolithic lattice module (Fig. 4).

A breakthrough has been made in developing thin-walled modules with internal reinforcement.

This development has now entered the stage of ground simulation testing.

In addition, the Institute of Aerospace Materials and Technology has also carried out the development of TA7ELI powdered titanium alloy impellers for low-temperature use in engines (Fig. 5).

The tensile properties of the material at room temperature and low temperature have already exceeded the performance standards of forgings.

The material’s plasticity at low temperature has reached a higher level.

Additionally, the material has passed the 1,800-second vacuum over-rotation simulation test, fulfilling the design requirements.

Superplasticization of Titanium Alloys

Overcoming Titanium Alloy Limitations with SPF/DB Technology

The introduction of the new superplastic forming/diffusion bonding (SPF/DB) technology in the 1970s provided a new way to overcome the limitations of titanium alloys, which were expensive to form and difficult to machine.

By taking advantage of titanium’s good superplasticity and diffusion joining characteristics, manufacturers can realize the forming and joining process in a single thermal cycle.

This results in a 30% weight reduction and a 50% cost saving in general components.

SPF/DB Technology: A Game Changer for Aerospace Manufacturing

Now, titanium alloy SPF/DB technology has become an advanced manufacturing method.

It promotes the development of modern aerospace structural design concepts and breaks through traditional sheet metal forming methods.

The development and application level of this technology has become a symbol of a country’s aerospace production capacity and development potential.

The world’s major aircraft manufacturers, such as Boeing, Pratt & Whitney, have established their own SPF / DB production and research base, of which the U.S. Hughes, BAE and other companies in the SPF / DB technology at the forefront of the world.

Real-World Applications and Benefits of SPF/DB in Aerospace

The titanium alloy superplastic forming (SPF) process has been widely used in the manufacturing of missile casings, propellant tanks, fairing spherical cylinders, corrugated plates, engine components, and more.

By using the SPF/DB (Superplastic Forming/Diffusion Bonding) combination process, manufacturers can produce non-circular cross-section and low-profile monolithic Ti-6Al-4V titanium alloy inlets.

This process can reduce production costs by 30% to 40%, and decrease the overall weight by 25% to 30%.

It can truly be described as a perfect example of “slimming” deformation.

Application Prospects and Future Development Trends

Titanium’s Potential and Challenges

As a resource not scarce on earth, titanium has not been widely used for many years, but its application potential, especially in aerospace, is huge.

There is a big resistance between the rich resources and the big market, which is attributed to the existence of technical and economic problems.

The development of high-performance and low-cost aerospace materials is an inevitable trend in the development of future aerospace models.

How to optimize the technology to improve the performance of titanium alloys and reduce the cost of titanium alloys will be the future development of the titanium industry is a strategic key issue.

Advanced Technologies Expanding Titanium Applications

Compared with cast titanium alloy, powder titanium alloy has fine and uniform internal organization, no segregation of components, and better performance than cast titanium alloy.

High-performance powder titanium alloy has been used in advanced aerospace key components.

Superplastic forming / diffusion connection of new technology, for the development of titanium alloys provide a broad space for development.

By replacing expensive assemblies, machined parts, and faulty repaired structures with superplasticized/diffusion-joined structural components, manufacturers can improve efficiency.

Additionally, reducing the lead time for assemblies that require many tools will further benefit production.

Titanium: The Newcomer with Exceptional Aerospace Potential

Superplasticized/diffusion-joined connections are expected to have a significant impact on the future of aerospace.

Titanium is 10 times more abundant than copper and is the “third metal” after iron and aluminum.

It is abundant, but it has only been industrially produced for more than 60 years, making it what is known figuratively as a “baby metal” compared to centuries-old aluminum and magnesium.

Nowadays, it is the newborn of this metal family that shines on the stage of the aerospace industry with its unique and superior performance, and glitters in the special and demanding environment of aerospace.