China CNC Milling » Blog » Research on the Processing Technology of Galvanized Aluminum-Magnesium ZAM Steel Plates

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Performance Characteristics of Hot-Dip Galvanized Aluminum-Magnesium Steel Sheet

The ZAM steel plate coating is composed of a Zn-Al (16%, by mass, throughout the text) -Mg (3%) alloy, which has a very fine and dense microstructure.

ZAM steel plates are galvanized steel plates with high corrosion resistance.

The product name “ZAM” is derived from the abbreviated symbols of the elements zinc, aluminum, and magnesium (Zn-Al-Mg).

ZAM steel plates undergo hot-dip galvanizing processing, resulting in a special anti-corrosion coating with strong corrosion resistance.

Their corrosion resistance is 10–20 times that of traditional hot-dip galvanized steel plates and 5–8 times that of hot-dip aluminum (5%) zinc steel plates.

Additionally, under specific material conditions and usage environments, its corrosion resistance even surpasses that of high-aluminum (55%) zinc-coated steel plates.

This product maintains excellent corrosion resistance even in harsh environments.

It can replace the hot-dip galvanizing (post-dip) or post-painting processes used for profiles.

In this way, it helps streamline production processes.

Compared to ordinary galvanized products, ZAM steel plates have several advantages.

They offer a longer service life, a thinner coating, and extremely high corrosion resistance.

This makes them a resource-saving and environmentally friendly product.

Magnesium-aluminum-zinc-coated steel sheets exhibit excellent processing performance even under severe conditions.

They perform well in stretching, stamping, and bending.

In bent areas, they provide superior corrosion resistance compared to traditional hot-dip galvanized steel sheets.

The coating has high hardness and superior scratch resistance compared to other galvanized steel sheets.

A distinctive feature of magnesium-aluminum-zinc-coated steel sheets is the self-healing function of the coating at the cut edges.

The finished products do not require additional post-coating or painting processes.

They are widely used in fields such as photovoltaics, automobiles, aviation, aerospace, electronics, and rail transportation.

Corrosion Protection Mechanism of Cut Ends of Galvanized Aluminum-Magnesium Steel Plates

Corrosion Mechanism of Cut Ends of Galvanized Aluminum-Magnesium Steel Sheets

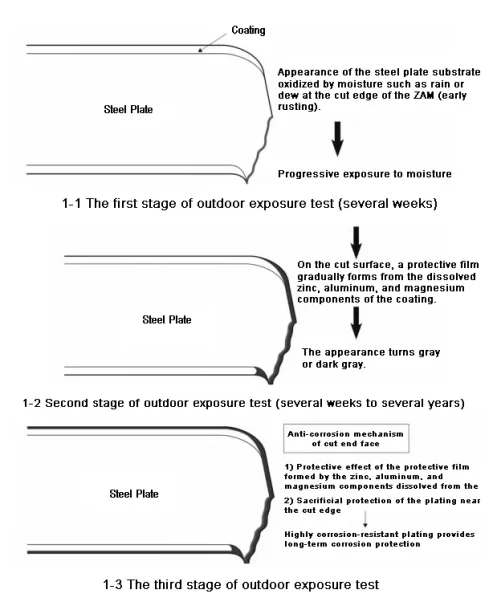

According to research conducted by Nisshin Steel in Japan, the corrosion mechanism of the cut end face of galvanized aluminum-magnesium steel sheets is shown in Figure 1.

The analysis in Figure 1 clearly shows that the cut end face of ZAM steel plates has a self-healing function of the corrosion-resistant coating.

Comparison of Long-Term Corrosion Resistance of Cut Ends in Salt Spray Tests (SST) and Cyclic Corrosion Tests (CCT)

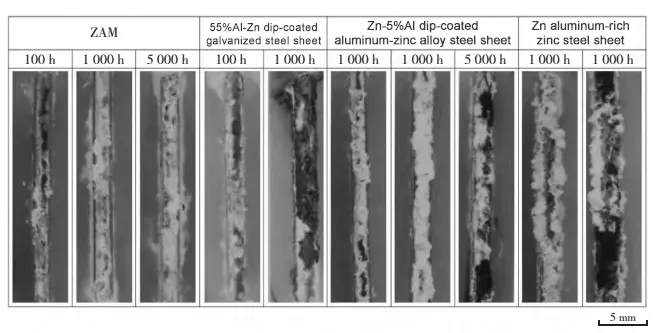

The occurrence of red rust on the cut ends of various galvanized steel plates was observed under salt spray testing and cyclic corrosion testing.

The results are shown in Figure 2.

The samples had a thickness of 3.2 mm, coating adhesion of 120/120 g/m², and no chromate treatment.

In the above corrosion tests, ZAM steel sheets showed better resistance to red rust.

Their performance was superior to that of hot-dip galvanized sheets, hot-dip galvanized aluminum-zinc alloy sheets, and aluminum-rich (55%) zinc sheets.

ZAM Steel Sheet Metal Processing Technology

In order to fully utilize the performance characteristics of ZAM plates and maintain their effectiveness, certain rules must be followed during sheet metal processing.

This is especially important for taking advantage of the coating’s self-healing function on the cut end face.

Through sufficient practice, guidelines have been established for each process, including blanking, deburring, bending, riveting, packaging, storage, and transportation.

Cutting Process

The amount of raw materials collected each time should not be excessive, as this helps minimize the risk of scratches.

In addition, no other sheets or items should be stacked on top of ZAM steel plates.

All ZAM steel plates must be cut using CNC punching or stamping processes. Combined punching should be used as little as possible.

No other thermal processing methods should be employed.

This is primarily because the cut edges produced by stamping have rounded edges, bright edges, and fracture edges.

The rounded edges and bright edges are covered by a coating, which ensures that the coating on the cut edges can self-heal.

In contrast, the cut edges produced by commonly used laser cutting have no coating, and the edges may have slag and carbides, which are detrimental to the coating’s self-healing ability.

When programming material cutting, use riveted nuts, and bolts should be riveted from the front side of the stamping part whenever possible.

When using CNC punching, confirm the surface condition of the material.

During programming, avoid scratches caused by uncoiling, and then produce using double-sided film protection.

Remove oil before applying the film, and attach part labels to the protective film.

The blanking process should be assigned to specific machines and operators.

During processing, stamping dies should be replaced and sharpened in a timely manner to ensure that burrs on CNC-punched parts remain within reasonable limits.

Deburring Process

When removing nodes, connection points, and burrs, the following principles should be followed:

1) Filing should only be performed from the front side of the stamping part.

The file should move from the front side to the back side of the stamping part, but the bright band on the sheared surface must not be filed.

Only the non-bright band on the torn surface may be filed.

The bright band is part of the coating penetration zone and serves a corrosion-resistant function.

2) The principle is to protect the special coating of ZAM steel plates from damage.

3) The principle is to ensure that the dimensional positioning during bending is not affected.

4) The principle is that after removing nodes, connection points, and burrs, they should not cause cuts or abrasions to the hands or gloves.

5) Electric tools must not be used.

Nodes formed by the edges of the front side of the punch are not processed.

Nodes formed by the edges of the back side of the punch are removed using a small file, without damaging the material surface.

Connection points and burrs formed by the punch are removed using a small file.

Bending Process

Protective measures must be taken during the bending process to prevent indentations from forming.

If the protective film does not provide adequate protection, paper padding must be used during bending to prevent indentations.

When riveting nuts, only the protective film on the area to be riveted must be removed, and insulating paper must be placed underneath.

When inspecting component dimensions, remove the corresponding surface protective film first.

The bending dimension tolerances for all bent components must be controlled within ±0.3 mm, with bending angles converted to linear dimensions for control.

For existing dies that cannot meet drawing requirements during bending, new dies must be manufactured; no machining allowances should be left after bending.

All parts must be processed using fixed bending dies and machinery.

When storing ZAM steel plates after bending, avoid stacking them.

During storage and transportation, they must be protected with bubble wrap.

After bending, inspect the hole spacing marked with tolerances.

The upper and lower dies of the bending machine must not be arbitrarily changed or transferred; the same product must use fixed-specification upper and lower dies.

Riveting Process

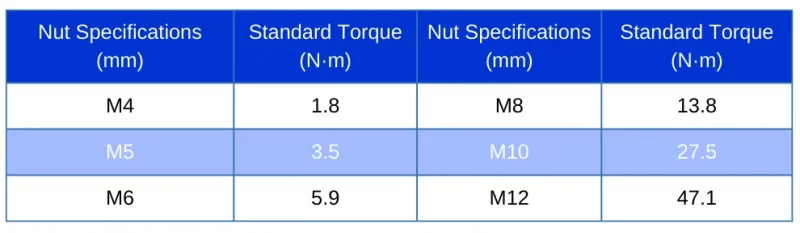

After the nut is riveted, a torque inspection must be performed (initial inspection, random inspection).

Only after passing the inspection can the process proceed to the next step.

Rivets that fail the inspection are scrapped and cannot be reworked.

For ZAM plates, the minimum penetration depth for M10 mm riveted nuts is 0.6 mm.

The torque standards for each nut specification are shown in Table 1.

Clamping and Riveting Processes

When performing clamping operations, ensure that there is no oil contamination at the contact points between the ZAM plate workpiece and the clamping tools.

This includes the drill press worktable, cutting tools, and clamping fixtures.

Preventing oil contamination helps avoid damage to the workpiece’s surface appearance.

When clamping ZAM plate workpieces, protective paper should be applied to prevent surface scratches.

When tapping, the machinist should promptly perform a go/no-go gauge inspection and use a thread tap appropriately.

Before riveting, the protective film on the surface of the ZAM steel plate must be thoroughly cleaned and degreased.

After removing the protective film, the finished product should retain the natural color of the material.

During riveting, clean gloves must be worn, and the coating must not be riveted inside the mounting frame or rivet holes.

Riveting operations should be performed on a platform, with cotton cloth or rubber mats placed on the platform to prevent surface scratches.

For countersunk rivets, the rivet head must not protrude above the plate surface after riveting.

Storage, Transshipment, Packaging, and Transportation Processes

ZAM steel plates, components, and finished products should be stored in a dry, clean environment to prevent the formation of oxidation spots on the surface of the plates.

During packaging, storage, and transportation, measures must be taken to prevent rain and moisture.

This helps avoid the formation of water vapor, oxides, and stains on the surface of the products, which cannot be removed.

Conclusion

Magnesium-aluminum-zinc-coated steel sheets have excellent corrosion resistance and processability.

These properties can help reduce production costs.

As a result, their application is expected to become increasingly widespread.

The number of domestic ZAM sheet raw material manufacturers and product types continues to increase.

Strengthening research and practice on the processing technology of magnesium-aluminum-zinc-coated steel sheets is essential.

Improving their processing level and yield rate will also effectively enhance their application across various industries.