China CNC Milling » Blog » Prospects for the Application of Zero-Point Quick-Change Fixtures Based on Intelligent Manufacturing in Machining

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Faced with increasing production demands year after year, under existing conditions, improving production efficiency and maximizing machine tool utilization have become the ongoing focus of the technical department.

Through years of effort, the impact of enhancing production efficiency by optimizing cutting parameters has become less pronounced.

From a technical perspective, the key to improving machine utilization lies in implementing off-machine setup.

This approach eliminates machine downtime caused by on-machine setup and reduces the time operators spend aligning tools on the machine, yielding particularly significant benefits for non-touch-triggered machines.

For such machines, alignment time typically accounts for approximately 10% of total machining time.

Early this year, a company planned to trial zero-point quick-change fixtures at its branch factory.

They invited globally renowned fixture suppliers like SCHUNK and LANG to discuss quick-change fixture designs tailored to their operational context.

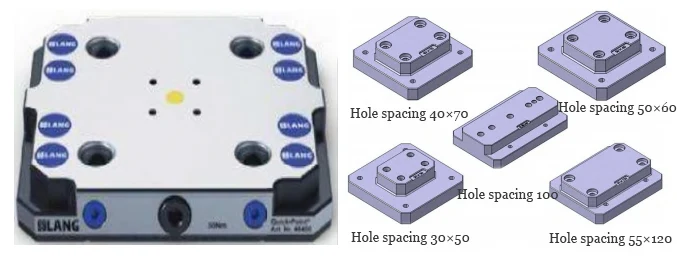

Considering cost control and the current structure of their parts, the company ultimately decided to purchase only LANG fixture bases, designing and manufacturing the adapter plates themselves.

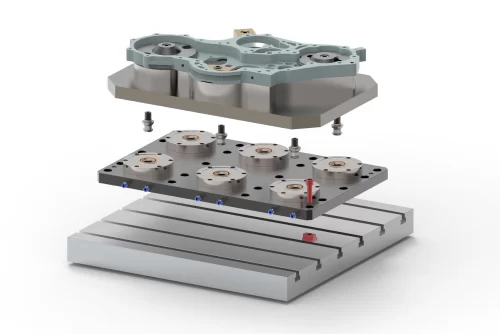

The selected fixture base and three-dimensional models of the five adapter plate types are shown in Figure 1.

Zero-Point Quick-Change Fixture Introduction

The zero-point quick-change fixture establishes a high-precision standard interface between machine tools and fixtures, featuring automatic locking functionality.

Pneumatic or hydraulic control enables unlocking for mounting and dismounting adapter plates, along with automatic clamping.

These adapter plates connect to workpieces, facilitating off-machine clamping and allowing for immediate replacement of workpieces and adapter plates as production demands require.

Quick-change fixtures significantly reduce tooling changeover time while enhancing changeover precision.

The following section provides a brief overview of the structural design and operating principles of these fixtures.

Structural Forms of Zero-Point Quick-Change Positioners

Currently, two primary zero-point positioning structures dominate the market.

The first is the positioning joint structure, as shown in Figure 2.

This third-generation ball-locking zero-point quick-change system comprises two components—the zero-point positioner and the positioning joint—making it well-suited for heavy-duty and large-scale machining applications.

Second is the cross-key positioning structure, as shown in Figure 3.

This structure primarily consists of three components: a zero-point locator, a support plate, and a tension pin. It features a compact and small design.

However, because it provides relatively low clamping force, manufacturers generally use it for small parts, precision machining, and electrical discharge machining.

This makes it suitable for precisely processing small components.

Based on the basic characteristics of the part, select the locating joint structure.

System Principle of Zero-Point Quick-Change Fixtures

Depending on the specific equipment and part type, operators install the appropriate zero-point quick-change fixtures on the machine tool.

These fixtures can be used individually or in sets.Secure the zero-point quick-change fixture to the machine tool worktable using clamping plates.

Pre-assemble the part and connector to the adapter plate via threaded connections (this constitutes the off-machine clamping stage).

Insert the assembled part-adapter plate unit into the four holes of the zero-point quick-change fixture.

Tighten the locking holes using a hex wrench, which applies approximately 2 tons of clamping force to the assembly.

Typically, locate the zero-point quick-change fixture on the machine tool worktable, mark this as the zero point, and set up the coordinate system based on actual machining requirements to achieve the fixture’s zero-point positioning function.

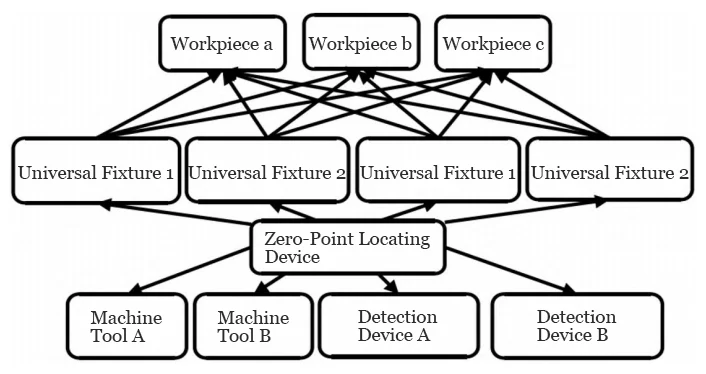

Due to the uniformity of the zero-point quick-change fixture, the workpiece’s zero point remains constant when moving between workstations, processes, or machines.

This enables precise and rapid tooling clamping, eliminates the need for re-alignment, ensures continuous operation, and facilitates seamless integration between the fixture, machine, and parts, as illustrated in Figure 4.

Application of Zero-Point Quick-Change Fixtures

Hydraulic housing mechanisms feature complex structures, demanding high machining precision and presenting significant processing challenges.

Production relies heavily on fixtures to meet machining requirements.

Additionally, parts production typically involves batch feeding, predominantly supporting small-batch production modes.

The high frequency of switching between different part machining tasks leads to increased fixture changeover rates.

Whenever operators change fixtures, installing new ones on the worktable inevitably requires time-consuming setup and alignment.

Compounding this, the accuracy of internal fixture installations is often suboptimal, potentially resulting in completed installations only to discover part-fixture interference or mismatch.

Zero-point quick-change systems drastically reduce fixture changeover time, enabling rapid, precise part mounting. This enhances equipment uptime and boosts machine tool utilization rates.

Key advantages

Zero-point quick-change fixtures offer several key advantages.

First, they enable off-machine clamping, reducing machine downtime.

Off-machine clamping involves pre-setting fixtures at a presetting station without interrupting machine operation.

Part clamping and adjustment occur concurrently with machining, eliminating traditional shutdowns for setup while boosting clamping efficiency.

A fixture presetting station is illustrated in Figure 5.

Second, it enables multi-process and multi-variety clamping of parts.

Once operators establish the zero-point quick-change fixture, the adapter plate becomes standardized.

As long as a part’s mounting can be compatible with the five types of adapter plates, it means these parts can be interchangeable.

Third, it offers high-precision repeat positioning capability.

Currently, measurement errors arising from mismatched machining and measurement reference points persistently disrupt workshop production targets.

The zero-point quick-change fixture enables measurement of parts while still clamped, ensuring alignment between machining and measurement reference points to eliminate measurement errors, as illustrated in Figure 6.

Fourth, the foundation for achieving flexible manufacturing cells.

To achieve flexible production of multiple product varieties, manufacturers must implement flexible tooling.

The essential prerequisite for flexible tooling is achieving rapid changeover with precise positioning—zero-point quick-change fixtures effectively address this requirement.

Concluding Remarks

Zero-point quick-change tooling systems can revolutionize part machining processes and production models, streamlining scheduling, freeing up labor, and significantly reducing fixture and part setup time on machines.

This enhances machining efficiency and precision. Zero-point quick-change tooling is the prerequisite and foundation for realizing smart manufacturing in the near future.

Manufacturers can achieve smart manufacturing of small-batch, high-variety parts only by using interchangeable tooling.