China CNC Milling » Blog » Properties and Processing of Plastics such as PS, HIPS, and PMMA

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

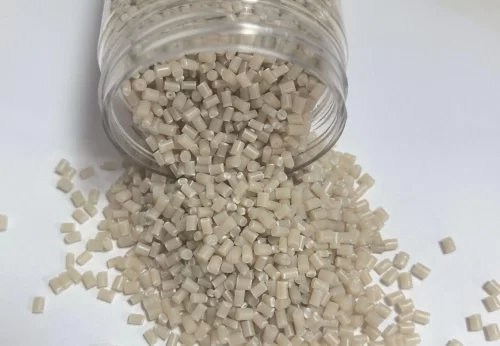

This article provides an overview of the fundamental properties and processing characteristics of commonly used injection-molding plastics.

From amorphous materials such as PS, ABS, PC, and PVC to crystalline plastics such as PE, PP, PA, and POM, each material exhibits unique behaviors in flowability, heat resistance, shrinkage, moisture absorption, and molding requirements.

By understanding these material differences, manufacturers can optimize processing conditions, improve product quality, and reduce defects during molding.

PS

Properties of PS

PS is an amorphous polymer with excellent flowability and low water absorption (less than 0.2%), making it a transparent plastic that is easy to process and form.

Its products achieve light transmittance of 88-92%, exhibit strong colorability, and possess high hardness.

However, PS products exhibit high brittleness and susceptibility to internal stress cracking.

They have poor heat resistance (60-80°C), are non-toxic, and possess a specific gravity of approximately 1.04 g/cm³ (slightly greater than water).

Processing Characteristics of PS

PS has a melting point of 166°C. Optimal processing temperatures generally range from 185 to 215°C, with a decomposition temperature of approximately 290°C, resulting in a relatively wide processing temperature window.

PS material does not require drying prior to processing. Due to its high melt index (MI) and excellent flow properties, injection pressure can be set lower.

PS has a low specific heat capacity, enabling rapid cooling and solidification in molds with adequate heat dissipation.

Its cooling rate exceeds that of most standard materials, allowing for earlier mold opening.

Both plasticization and cooling times are relatively short, reducing overall cycle times.

The gloss of PS products improves with increased mold temperature.

HIPS

HIPS Properties

HIPS is a modified material of PS, containing 5-15% rubber content. Its toughness is approximately four times that of PS, with significantly enhanced impact strength.

It retains PS‘s advantages of excellent processability and strong dyeability. HIPS products are opaque.

HIPS exhibits low water absorption and does not require pre-drying during processing.

Processing Characteristics of HIPS

Containing 5-15% rubber in its molecular structure, HIPS exhibits reduced flowability to some extent.

Higher injection pressure and molding temperatures are recommended.

Its cooling rate is slower than PS, necessitating sufficient holding pressure, holding time, and cooling time.

The molding cycle is slightly longer than PS, with an optimal processing temperature range of 190-240°C.

A distinctive “white edge” phenomenon occurs in HIPS parts.

This can be mitigated by increasing mold temperature and clamping force while reducing holding pressure and time.

However, water lines may become more pronounced in the finished product.

AS(SAN)

AS Performance

AS is a styrene-acrylonitrile copolymer that exhibits low susceptibility to internal stress cracking.

It offers high transparency, with a higher softening temperature and greater impact strength than PS.

Processing Characteristics of AS

The optimal processing temperature for AS is generally between 200-250°C.

This material readily absorbs moisture and requires drying for over one hour prior to processing.

Its flowability is slightly inferior to PS, thus requiring slightly higher injection pressure. Mold temperature should be maintained between 45-75°C.

ABS

Properties of ABS

ABS is a terpolymer of acrylonitrile, butadiene, and styrene, exhibiting high mechanical strength and excellent overall properties characterized by toughness, resilience, and rigidity.

As an amorphous polymer, ABS is a versatile engineering plastic with diverse varieties and extensive applications, also known as a “general-purpose plastic” (MBS refers to transparent ABS).

It readily absorbs moisture, has a density of 1.05 g/cm³ (slightly heavier than water),low shrinkage rate (0.60%), dimensional stability, and is easy to process and mold.

Processing Characteristics of ABS

1. ABS exhibits significant moisture absorption and humidity sensitivity.

Thorough drying and preheating are essential prior to molding, with moisture content strictly controlled below 0.03%.

2. Unlike other amorphous resins, ABS exhibits low sensitivity of melt viscosity to temperature.

Although its injection temperature is slightly higher than PS, it lacks PS’s broad temperature tolerance range.

Blindly increasing temperature to reduce viscosity is ineffective; instead, enhance flowability by raising screw speed or injection pressure.

Optimal processing temperatures range from 190-235°C.

3. ABS exhibits medium melt viscosity, higher than PS, HIPS, and AS, necessitating higher injection pressure for molding.

4. Moderate injection speeds yield optimal results for ABS molding (except for complex, thin-walled parts requiring higher speeds). Gate areas are prone to surface defects.

5. ABS requires higher molding temperatures, with mold temperatures typically set between 45-80°C.

For larger products, the fixed mold (front mold) temperature should generally be about 5°C higher than the moving mold (rear mold).

6. ABS should not remain in the barrel at high temperatures for extended periods (less than 30 minutes), as prolonged exposure may cause decomposition and yellowing.

BS (K Material)

Properties of BS

BS is a styrene-butadiene copolymer characterized by moderate toughness and elasticity, low hardness (relatively soft), and excellent transparency.

It has a density of 1.01 g/cm³ (similar to water). This material is easy to color, exhibits good flow properties, and is readily moldable.

Processing Characteristics of BS

The optimal processing temperature range for BS is generally 190-225°C, with a recommended mold temperature of 30-50°C.

This material should be dried prior to processing. Due to its good flow properties, injection pressure and injection speed can be set lower.

PMMA

Properties of PMMA

PMMA is an amorphous polymer commonly known as acrylic glass.

It exhibits excellent transparency and good heat resistance (with a heat deflection temperature of 98°C).

Products made from it possess moderate mechanical strength and low surface hardness, making them susceptible to scratches from hard objects that leave marks.

Compared to polystyrene (PS), it is less prone to brittle fracture. Its density is 1.18 g/cm³.

Processing Characteristics of PMMA

PMMA processing demands strict conditions, as it is highly sensitive to moisture and temperature. Thorough drying is essential prior to processing.

Its melt viscosity is relatively high, requiring molding at elevated temperatures (225-245°C) and pressures. Mold temperatures between 65-80°C are optimal.

PMMA exhibits poor stability; prolonged exposure to high temperatures or extended dwell times at elevated temperatures can cause degradation.

Screw speeds should not be excessively high (around 60% is sufficient).

Thicker PMMA parts are prone to “voids” in the interior, necessitating processing with large gates and employing the method of “low material temperature, high mold temperature, and slow injection speed.”

PE

Properties of PE

PE is the most widely produced plastic, characterized by its softness, non-toxicity, low cost, and ease of processing.

It is a typical crystalline polymer. Among its various types, LDPE and HDPE are commonly used.

These are semi-transparent plastics with low strength and a density of 0.94 g/cm³ (lower than water).

LDPE is softer (commonly known as soft plastic), while HDPE is known as rigid plastic.

It is harder than LDPE, has poor light transmission, and exhibits high crystallinity.

PE offers excellent chemical resistance and is corrosion-resistant, but it is difficult to print on.

Processing Characteristics of PE

The most notable feature of PE molded parts is their high molding shrinkage rate, which makes them prone to shrinkage and deformation.

PE resin has low moisture absorption and does not require drying.

PE has a wide processing temperature range and is resistant to decomposition (decomposition temperature is 320°C).

Higher pressure results in higher part density and reduced shrinkage.

PE has moderate flowability, requiring strict control of processing conditions and maintaining constant mold temperature (40-60°C).

PE crystallinity is influenced by molding conditions. It exhibits a high cold-set temperature; lower mold temperatures result in reduced crystallinity.

During crystallization, anisotropic shrinkage causes internal stress concentration, making PE parts prone to deformation and cracking.

Placing the product in an 80°C water bath can provide some stress relief.

During molding, slightly elevated material and mold temperatures are preferable. Injection pressure should be kept relatively low while ensuring part quality.

Mold cooling requires particularly rapid and uniform cooling, as the product will be hot upon ejection.

PP

Properties of PP

PP is a crystalline polymer and the lightest among common plastics, with a density of only 0.91 g/cm³ (lower than water).

Among general-purpose plastics, PP offers the best heat resistance, featuring a heat deflection temperature of 80-100°C and the ability to withstand boiling water.

It exhibits excellent stress crack resistance and high flexural fatigue life, earning it the nickname “unbreakable plastic.” PP’s overall performance surpasses that of PE materials.

PP products are lightweight, highly resilient, and chemically resistant.

PP’s drawbacks include: low dimensional accuracy, insufficient rigidity, poor weather resistance, susceptibility to “copper damage,” and post-shrinkage tendencies.

After demolding, it is prone to aging, brittleness, and deformation.

Processing Characteristics of PP

PP exhibits good flowability at its melting temperature and excellent molding properties.

Two key characteristics define its processing behavior: First, the viscosity of PP melt decreases significantly with increasing shear rate (relatively unaffected by temperature).

Second, it demonstrates high molecular orientation, resulting in substantial shrinkage.

Optimal processing temperatures for PP range from 200-300°C.

It exhibits good thermal stability (decomposition temperature: 310°C), but prolonged residence in the barrel at high temperatures (270-300°C) may cause degradation.

Since PP viscosity decreases significantly with increased shear rate, raising injection pressure and injection speed improves flowability, reducing shrinkage deformation and sink marks.

Mold temperature should be controlled within 30-50°C. PP melt can penetrate narrow mold gaps, causing flash.

During melting, PP absorbs substantial heat of fusion (high specific heat), resulting in hot parts upon ejection. PP material requires no drying before processing.

Its shrinkage rate and crystallinity are lower than PE.

PA

Properties of PA

PA is also a crystalline plastic with numerous varieties. Common types used in injection molding include nylon 6, nylon 66, nylon 1010, and nylon 610.

Nylon exhibits toughness, wear resistance, and self-lubricating properties.

Its primary advantages include high organic mechanical strength, excellent toughness, fatigue resistance, smooth surface, low friction coefficient, wear resistance, heat resistance (suitable for long-term use up to 100°C), corrosion resistance, lightweight parts, easy dyeing, and ease of molding.

Key disadvantages of PA include: high moisture absorption, stringent injection molding requirements, poor dimensional stability, and hot products due to its high specific heat capacity.

PA66 is the highest-strength and most widely used variety in the PA series.

Its high crystallinity confers superior rigidity, hardness, and heat resistance.

PA1010, first developed in China in 1958, is semi-translucent with low density, offering greater elasticity and flexibility.

It exhibits lower moisture absorption than PA66 and reliable dimensional stability.

Processing Characteristics of PA

PA readily absorbs moisture and must be thoroughly dried before processing, with moisture content controlled below 0.3%.

Well-dried raw material yields high-gloss products, whereas insufficient drying results in a rougher finish.

PA does not soften gradually as heating temperature increases but instead softens within a narrow temperature range near its melting point.

Its melting point is distinctly defined, and flow occurs once this temperature is reached (unlike materials such as PS, PE, or PP).

PA exhibits significantly lower viscosity than other thermoplastics and has a narrower melting temperature range (approximately 5°C).

It possesses excellent flowability, facilitating mold filling but also prone to flash formation. Nozzles are susceptible to “dripping,” necessitating higher suction pressure.

With its high melting and solidification points, molten material may solidify within the mold if temperatures drop below the melting point, hindering complete filling.

Therefore, high-speed injection is essential (especially for thin-walled or long-flow parts). Nylon molds require thorough venting measures.

PA exhibits poor thermal stability in the molten state and is prone to degradation.

Barrel temperature should not exceed 300°C, and melt residence time in the barrel should not exceed 30 minutes.

PA demands precise mold temperature control, which can be used to regulate crystallization and achieve desired properties.

Optimal mold temperatures for PA range from 50-90°C. Processing temperatures for PA1010 are best at 220-240°C, while PA66 requires 270-290°C.

Depending on quality requirements, finished PA products may undergo annealing or moisture conditioning.

POM

Properties of POM

POM is a crystalline plastic with excellent rigidity, commonly known as “Acetal.”

It possesses outstanding properties including fatigue resistance, creep resistance, wear resistance, and heat resistance.

POM exhibits low moisture absorption, with a density of 1.42 g/cm³ and a relatively high shrinkage rate of 2.1%, making dimensional control challenging.

Its heat deflection temperature is 172°C.

Processing Characteristics of POM

POM does not require drying prior to processing. It is best to preheat the material during processing (around 100°C), which improves dimensional stability of the product. POM has a narrow processing temperature range (195-215°C).

Prolonged residence time in the barrel or temperatures exceeding 220°C will cause decomposition.

Screw speed should not be excessively high, and residual material should be minimized.

POM exhibits significant shrinkage, making it prone to shrinkage defects or deformation.

POM has a high specific heat capacity, requiring elevated mold temperatures (80-100°C).

Molded parts remain extremely hot after ejection, necessitating precautions against burns.

POM is best processed under conditions of medium pressure, moderate speed, and high mold temperatures.

PC

PC Properties

PC is an amorphous plastic with excellent transparency.

It offers outstanding comprehensive properties, including high mechanical strength, good toughness, excellent heat and weather resistance, high dimensional stability, easy colorability, and low water absorption.

PC has a heat deflection temperature of 135-143°C and can be used long-term at operating temperatures of 120-130°C.

Its disadvantages include: limited chemical resistance, high melt viscosity, poor flowability, extreme sensitivity to moisture, and susceptibility to internal stress cracking.

Processing Characteristics of PC

PC material is temperature-sensitive, with its melt viscosity decreasing significantly as temperature rises, accelerating flow.

It is insensitive to pressure, so increasing temperature is the method to enhance flowability.

PC material must be thoroughly dried before processing (around 120°C), with moisture content controlled below 0.02%.

PC material should be molded under conditions of high material temperature, high mold temperature, and high pressure at slow speeds.

Mold temperature is best controlled around 80-110°C, with a suitable molding temperature of 280-320°C. PC products are prone to surface flash and gate lines, exhibit significant internal residual stress, and are susceptible to cracking.

Consequently, PC material demands higher precision in molding. PC has low shrinkage (0.5%) and minimal dimensional variation.

Products molded from PC can undergo annealing to relieve internal stress.

EVA

Properties of EVA

EVA is an amorphous plastic, non-toxic, with a density of 0.95 g/cm³ (lighter than water).

Its products exhibit poor surface gloss, excellent elasticity, softness, light weight, low mechanical strength, good flowability, and ease of processing and molding.

It has a relatively high shrinkage rate (2%). EVA can be used as a carrier for color masterbatches.

Processing Characteristics of EVA

EVA molding operates at low temperatures (160-200°C) with a wide range tolerance.

Mold temperatures should be kept low (20-45°C). The material requires drying prior to processing (drying temperature: 65°C).

During processing, mold and material temperatures should not be excessively high, as this may result in a rough surface finish.

EVA products tend to adhere to the front mold; therefore, snap-fit designs are recommended for sprue runners and cold runner cavities.

Temperatures exceeding 250°C may cause decomposition.

EVA processing is best achieved under “low temperature, medium pressure, and moderate speed” conditions.

PVC

Properties of PVC

PVC is an amorphous plastic with poor thermal stability and susceptibility to thermal decomposition.

It is flame-retardant (exhibits good flame resistance), has high viscosity, and poor flowability.

PVC comes in various types, categorized as soft, semi-rigid, and rigid PVC.

Its density ranges from 1.1 to 1.3 g/cm³ (heavier than water), with a high shrinkage rate (1.5–2.5%).

PVC products exhibit poor surface gloss (though recent American research has developed a transparent rigid PVC comparable to polycarbonate).

Processing Characteristics of PVC

PVC has a narrower processing temperature range (160-185°C), making it more challenging to process with higher technical demands.

Drying is generally unnecessary during processing (if required, perform at 60-70°C). Mold temperatures should be lower (20-40°C).

PVC processing is prone to air lines and black streaks; processing temperature must be strictly controlled.

Screw speed should be low (below 50%), with minimal residual volume and back pressure not excessively high.

Molds require effective venting. PVC material should not remain in the high-temperature barrel for over 15 minutes.

Compared to PVC, a larger water level is preferable for material feeding.

Molding is best achieved under “medium pressure, slow speed, low temperature” conditions.

Compared to PVC products, they are more prone to sticking to the front mold. The opening speed (first stage) should not be too fast.

It is preferable to design the sprue as a pull-tab type at the cold runner cavity.

Before stopping the machine after processing PVC material, promptly clean the barrel with PS sprue material (or PE material) to prevent PVC decomposition, which produces Hd↑ and corrodes the screw and barrel inner walls.

PPO

Performance Characteristics of PPO

PPO (NORLY) is an engineering plastic with outstanding comprehensive properties.

It exhibits higher hardness than PA, POM, and PC, along with high mechanical strength, excellent rigidity, superior heat resistance (heat deflection temperature of 126°C), high dimensional stability (shrinkage rate of 0.6%), and low moisture absorption (less than 0.1%).

Its disadvantages include instability to ultraviolet light, high cost, and limited market penetration.

Processing Characteristics of PPO

PPO exhibits high melt viscosity, poor flowability, and demanding processing conditions.

Prior to processing, it must be dried at 100-120°C for 1-2 hours.

Molding temperatures range from 270-320°C, with mold temperatures ideally controlled at 75-95°C.

Processing requires “high temperature, high pressure, and high speed” conditions. During injection molding, jet streaks (snake patterns) readily form ahead of the sprue. Larger sprue runners are preferable.

Conclusion

Different plastics exhibit distinct physical properties and processing behaviors, making it essential to select suitable molding parameters based on material characteristics.

Proper control of temperature, pressure, drying, mold temperature, and injection speed ensures stable production and minimizes issues such as deformation, brittleness, internal stress, and shrinkage.

A comprehensive understanding of these materials enables more efficient injection molding, more consistent product performance, and improved manufacturing reliability.