China CNC Milling » Blog » Practical Exploration of Automation Technology in Machining Manufacturing

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

The machinery manufacturing industry serves as a pillar of the national economy, with its development level directly impacting the nation’s overall competitiveness.

Intelligent manufacturing, characterized by digitalization, networking, and intelligence, is spearheading a new social transformation in manufacturing.

Its production model is undergoing a strategic shift. It is moving away from traditional methods that rely on manual expertise and conventional machine tools.

It is adopting modern production modes characterized by automation, flexibility, and intelligence.

By deeply integrating advanced control technologies, information technologies, and mechanical equipment, automation technology significantly enhances processing efficiency and precision.

It also ensures consistent product quality. In addition, it reduces energy consumption and labor costs.

It further strengthens the production system’s ability to rapidly respond to diverse market demands.

Currently, automation technologies such as computer numerical control (CNC) technology, industrial robots, flexible manufacturing systems (FMS), and integrated intelligent inspection play a central role in modern automated processing.

Together, they form the core framework of these systems.

They drive production lines toward reduced or even unmanned operation, continuous and flexible running.

However, during practical implementation and deep integration, automation technology faces several challenges.

These include high investment costs and complex information exchange and coordination between multiple systems.

It also encounters “information silos” caused by inefficient production data flow.

Additionally, there is a shortage of multidisciplinary talent proficient in mechanical, electrical, control, and information technologies.

Therefore, thoroughly examining the practical application of automation technology in mechanical processing manufacturing is important.

Summarizing its advantages and existing issues also holds significant theoretical value.

In addition, it has practical significance.

This paper focuses on four core modules: CNC machining technology, robotic integration systems, flexible manufacturing units, and intelligent inspection systems.

It analyzes their application models in typical machining scenarios. It also examines their operational outcomes.

Drawing on practical case studies, it summarizes the economic benefits and technical bottlenecks resulting from automation implementation, proposing actionable development strategies.

Application of Automation Technology in Mechanical Manufacturing

Intelligent Evolution of CNC Machining Technology

Computer Numerical Control (CNC) machining technology stands as one of the earliest key technologies to achieve automation in mechanical manufacturing and forms the foundation of modern intelligent manufacturing.

In traditional machining, workers manually performed positioning, cutting path control, and parameter settings.

This approach led to issues such as significant fluctuations in machining accuracy. It also caused poor repeatability and low efficiency.

With advancements in automatic control theory and information technology, CNC systems have progressively transitioned from “program control” to “intelligent sensing and adaptive control.”

Common CNC machining technologies and their characteristics are summarized in Table 1.

| Technology Development Direction | Main Content and Functions | Application Advantages and Outcomes |

|---|---|---|

| Adaptive Machining Control | Real-time monitoring of spindle load, temperature, vibration, and other states; dynamic adjustment of feed rate and cutting parameters | Improves machining stability, extends tool life, and avoids machining defects |

| Graphical Programming and Toolpath Optimization | Integrated CAD/CAM operation; automatic generation of optimal tool paths and interference avoidance | Reduces programming time; improves efficiency and accuracy in complex surface machining |

| Embedded Sensing and Condition Monitoring | Integration of multiple sensors such as temperature, current, and acceleration; real-time monitoring of machine and tool conditions | Enables predictive maintenance and prevents quality issues caused by abnormal machining |

| Integrated Collaboration and Remote Control | Collaborative operation with robots, vision systems, edge computing, or cloud platforms; supports remote control and monitoring | Enables equipment networking, intelligent task scheduling, and remote fault diagnosis |

| Machining Database and Self-Learning Optimization | Uses big data to record historical machining conditions and results; intelligently optimizes machining parameters | Enables transfer of experiential models; improves first-pass machining accuracy and yield for new products |

Integrated Applications of Industrial Robots in Multi-Process Automation

1. Integrated Application Models

Typical models for integrating industrial robots with CNC machining equipment include robotic loading and unloading systems.

They also include multi-process collaborative machining cells. Another model is robot-vision system integration.

Additionally, there are integrated robot-inspection-sorting systems.

Robotic Loading/Unloading Systems.

These systems utilize end effectors and sensors to automatically grasp, position, and place workpieces.

They are commonly deployed around CNC machining centers, presses, and similar equipment.

Multi-Process Collaborative Machining Units.

Robots transfer workpieces between multiple machine tools to execute continuous multi-step operations, achieving fully automated control of the entire “machining-transfer-re-machining” process.

Robot-Vision Integration. Equipped with 2D/3D vision systems to identify workpiece orientation and position, enabling flexible gripping and clamping to accommodate varying batches and shapes of parts.

Robot + Inspection + Sorting Integrated System.

Enables automatic post-processing quality inspection and classification of products, reducing manual inspection steps.

2. Application Advantages

The integrated application of industrial robots in multi-process automation for machining significantly enhances production line flexibility and intelligence.

By replacing manual labor in repetitive, high-intensity tasks such as loading and unloading, material handling, clamping, and inspection, these systems improve operational efficiency.

They also enhance product consistency. In addition, they reduce human operational errors and workplace injury risks.

Simultaneously, their programmable and scalable nature enables rapid adaptation to diverse, small-batch processing demands.

This significantly enhances production systems’ responsiveness to market fluctuations.

It also improves resource allocation efficiency.

As a result, industrial robots become a pivotal technology and tool for advancing machining toward lean and intelligent manufacturing transformation.

3. Application Case

Taking the machining workshop of a high-end CNC machine tool manufacturer as an example, the workshop faced issues such as low manual loading and unloading efficiency, poor process handover, and significant production cycle fluctuations.

To address these problems, an automated production cell was introduced.

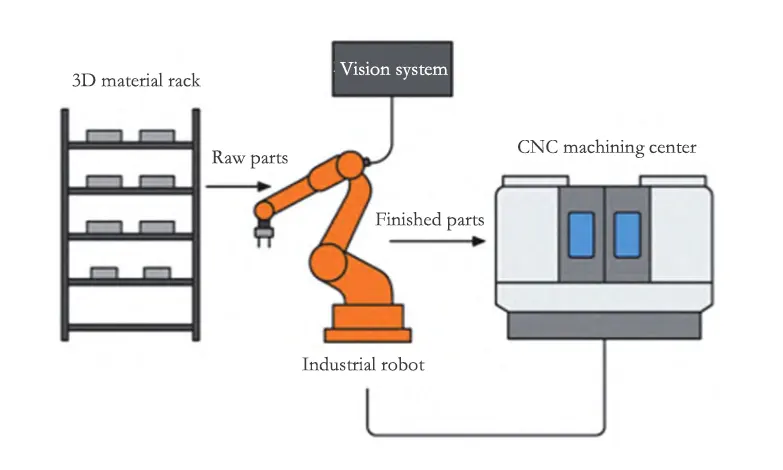

This cell comprises a six-axis industrial robot (Figure 1), a dual-station CNC machining center, a vertical storage rack, and a 2D vision system.

The system integrates a vertical storage rack, six-axis industrial robot, 2D vision system, and dual-station CNC machining center to form a closed-loop, unmanned processing workflow.

Workpiece blanks are neatly arranged in the left-side vertical rack.

Assisted by the 2D vision system, the six-axis industrial robot identifies the position and posture of blanks on the rack.

It then precisely feeds them into the dual-station CNC machining center’s fixture.

The robot automatically completes clamping and initiates the machining process.

Upon completion, the robot re-enters the processing zone to retrieve the finished part and transports it to the finished goods area or next process according to programmed settings.

The operational principle is illustrated in Figure 2.

This system reduces the single-piece processing cycle time from 82 seconds to 54 seconds, increasing production efficiency by approximately 34%.

Product clamping consistency is significantly enhanced, with the defect rate decreasing from 2.3% to 0.8%.

Concurrently, the workforce requirement is reduced from 6 to 2 personnel, substantially lowering labor costs.

Construction and Operation of Flexible Manufacturing Systems (FMS)

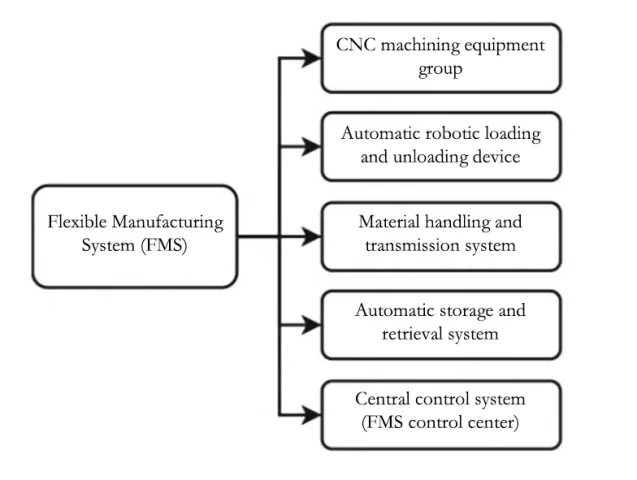

A Flexible Manufacturing System (FMS) is an automated production system comprising multiple CNC machining devices, automatic loading/unloading units, robots, material handling systems, and a central control system.

It offers high flexibility and automation levels, making it suitable for multi-variety, small-to-medium batch processing tasks.

The FMS can dynamically adjust equipment scheduling.

It can also reconfigure processes and reallocate resources in response to production plan changes.

This capability serves as a critical pathway for mechanical processing enterprises to achieve intelligent and flexible transformation.

The primary structure of an FMS is illustrated in Figure 3.

1) CNC Machining Equipment Cluster: Comprising multiple CNC lathes, machining centers, and similar devices, this forms the core apparatus for executing various cutting operations.

2) Robotic Automatic Loading/Unloading System: Handles workpiece clamping and transfer tasks, enhancing cycle time stability and machining accuracy.

3) Material Handling and Conveying System: Utilizes AGVs, conveyor belts, or rail-guided carts to automatically transport workpieces between stations.

4) Automated Storage and Retrieval System (AS/RS): Stores raw materials, semi-finished goods, and finished products, supporting automated storage/retrieval and inventory management.

5) Central Control System (FMS Control Center): Integrates scheduling, monitoring, diagnostics, and data acquisition functions to achieve unified coordination and optimized management of all system components.

During FMS operation, production orders are transmitted from the ERP system to the FMS control center for task decomposition and path planning.

The system optimally allocates processing stations and sequences based on product manufacturing routes.

It automatically selects available equipment and issues machining instructions.

The system assigns robots for loading and unloading. It also utilizes AGVs for material transport.

Throughout the process, the system continuously monitors and collects real-time data on machining status, equipment operating parameters, and processing quality.

Completed workpieces are sorted by the system to designated areas or conveyed to the next process.

Intelligent Inspection and Closed-Loop Quality Control

Traditional quality control methods reliant on manual sampling inspections struggle to meet production demands in automated and information-driven environments.

Intelligent inspection technology leverages sensors, machine vision, image processing, and AI algorithms to enable real-time monitoring, defect identification, and feedback control during manufacturing.

This establishes an efficient and reliable closed-loop quality management system.

Beyond final product inspection, intelligent inspection critically embeds detection nodes throughout the manufacturing process, creating a “detect-feedback-adjust” closed-loop mechanism.

Detection modules are integrated during production to dynamically capture key metrics such as dimensions, appearance, and thermal deformation.

The system analyzes inspection data against preset tolerance ranges.

For minor deviations, it automatically adjusts cutting parameters or tool compensation for real-time correction.

However, when errors exceed permissible limits, the system triggers machine shutdown or ejects the workpiece from the production line, preventing defective items from entering subsequent processes.

This system enables end-to-end quality control throughout the entire process.

Through its early warning and adjustment mechanisms, it controls potential defects at the source, significantly reducing scrap rates and supporting automated closed-loop production.

Analysis of Existing Issues

High Initial Investment Costs

Key equipment such as automated machinery, industrial robots, flexible manufacturing cells, and intelligent inspection systems carry relatively high unit prices.

Establishing a complete automated production line requires substantial capital investment from manufacturers.

Additionally, ongoing maintenance costs for system integration, debugging, operational support, and upgrades place significant financial pressure on small and medium-sized enterprises.

Poor System Integration and Compatibility

Inconsistent communication protocols and interface standards among different equipment manufacturers hinder seamless integration with new intelligent systems.

The presence of numerous legacy devices in manufacturing environments further complicates this integration.

This impedes overall system operational efficiency and flexibility.

Shortage of Multidisciplinary Technical Talent

The operation of automation systems involves multidisciplinary technologies spanning mechanical, electrical, software, and control engineering.

Existing manufacturing enterprises commonly face a situation where “operators lack skills and engineers lack integration capabilities,” making it difficult to handle tasks such as system configuration, maintenance, and secondary development.

This poses risks to the stable operation of automation systems.

Insufficient System Robustness and Environmental Adaptability

The complex working environments commonly encountered during processing—such as dust, oil mist, vibration, and temperature rise—can easily compromise the stability and lifespan of automated equipment, particularly sensors and vision systems.

This may lead to system misjudgments, failures, and other issues, thereby undermining the reliability of continuous operations.

Insufficient Data Interoperability and Intelligent Mechanisms

Despite the increasing number of manufacturing devices equipped with data collection and networking capabilities, the absence of unified industrial internet platforms and data standards makes data exchange between different systems challenging, resulting in “data silos.”

Furthermore, while vast amounts of data exist, the lack of efficient modeling, analysis, and intelligent decision-making mechanisms prevents it from being effectively converted into productive capacity.

Development Strategy

Promote Modular and Standardized Design

Accelerating the standardization of interfaces and unification of communication protocols for key automation modules among equipment manufacturers can reduce system integration complexity.

Modular design enables flexible combinations and on-demand deployment.

It allows small and medium-sized enterprises to select configurations based on production scale and product structure.

This approach alleviates one-time investment pressures.

Establish Smart Manufacturing Demonstration Workshops

Enterprises should be encouraged to establish small-scale smart demonstration units, or “lighthouse workshops.”

These units should focus on a specific typical process or product line.

They can then conduct end-to-end smart manufacturing pilots covering processing, inspection, warehousing, and data analysis.

Through demonstration applications, accumulate replicable experience and gradually expand to entire production lines or even entire factories.

Strengthening the Cultivation of Multi-Skilled Technical Talent

Collaborate with universities, vocational education institutions, and enterprises to establish an integrated industry-academia-research talent development mechanism.

Focus on cultivating multi-skilled technical professionals proficient in both mechanical processing techniques and automation integration, data analysis, and intelligent control.

Simultaneously advance the development of internal corporate training systems to enhance frontline employees’ capabilities in operating and maintaining automation systems.

Introducing Industrial Internet and Edge Computing Platforms

Enterprises should establish a data integration and sharing mechanism centered on the industrial internet platform.

This mechanism breaks down data silos between equipment, process, quality, and warehousing systems.

It enables cross-system scheduling and intelligent analysis.

Combined with edge computing deployment, this facilitates local real-time control and remote collaborative optimization, enhancing system responsiveness and adaptive capabilities.

Provide Policy and Financial Support

It is recommended that the government establish special funds or low-interest loans to support eligible smart manufacturing technical upgrade projects.

Promote the formulation of tax reduction and exemption policies related to smart manufacturing to encourage enterprises to increase investment in automation.

Simultaneously, guide financial institutions to develop financing tools tailored to the characteristics of small and medium-sized manufacturing enterprises, thereby lowering the threshold for intelligent transformation.

Conclusion

This paper systematically analyzes the application models and outcomes of key technologies—including CNC machining, industrial robot integration, flexible manufacturing systems (FMS), and intelligent inspection—in actual production.

It summarizes their significant advantages in enhancing production efficiency, ensuring product consistency, reducing labor costs, and promoting flexible manufacturing.

Simultaneously, the paper identifies constraints that hinder the widespread adoption of automation systems.

These constraints include substantial initial investment, complex system integration, a shortage of technical personnel, and data silos.

It also proposes a multi-dimensional development strategy for the future.

This strategy encompasses enhanced modular standardization, the promotion of demonstration units, training of multidisciplinary talent, development of industrial internet platforms, and policy and financial support.

This approach aims to provide enterprises with a feasible pathway for efficiently advancing intelligent transformation.