Blog

More to learn about rapid prototyping and manufacturing industry.

Magnesium vs. Aluminum Alloys: Performance in EV Drive Housings

New energy vehicles have emerged as a new engine for the global economy. However, the integration of power batteries and electric drive systems typically adds 200–500 kg to the vehicle's weight compared to conventional gasoline vehicles of the same class, resulting in reduced range and handling.

Current Research Status of Ultrasonic Cutting Processing for Aerospace Metallic Materials

Titanium alloys, high-temperature alloys, and other difficult-to-machine metallic materials are crucial raw materials for manufacturing key aerospace engine components such as turbine disks, blades, and casings.

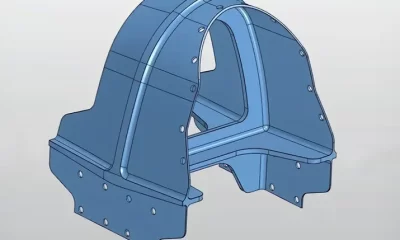

Quality Control of Large Structural Components in Digital Manufacturing Environments

With the increasingly deep and widespread application of digital technologies in aircraft design, manufacturing, and inspection, higher demands are placed on the manufacturing and assembly precision of aircraft products.

A Brief Analysis of Springback in Extruded Profile Bending

Currently, extruded profiles are widely used in various industries such as construction machinery and architecture. Since extruded profiles are typically produced through secondary processing of sheet metal and often feature hollow structures, the forming process experience for sheet metal cannot be directly applied to extruded profiles

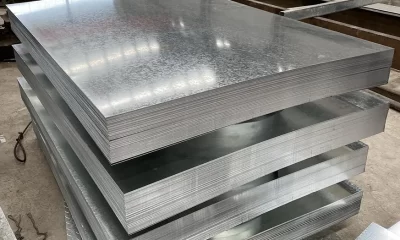

Research on the Processing Technology of Galvanized Aluminum-Magnesium ZAM Steel Plates

The ZAM steel plate coating is composed of a Zn-Al (16%, by mass, throughout the text) -Mg (3%) alloy, which has a very fine and dense microstructure.

How to process large radius sheet metal bending?

In sheet metal processing, there are sometimes requirements for bending with extremely large radii, but due to equipment limitations, it is often difficult to meet these manufacturing requirements. In such cases, solutions must be sought through process optimization.

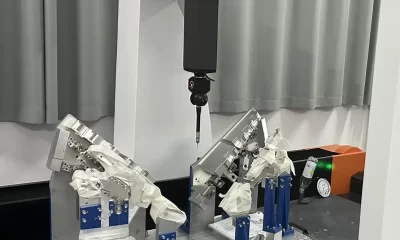

Application of Coordinate Measuring Machines in Improving the Accuracy of Geometric Measurement of Mechanical Parts

The geometric measurement accuracy of mechanical parts is a key factor in assessing product quality. Among these, the coordinate measuring machine (CMM), as a high-precision, high-efficiency inspection device, is increasingly widely applied in the mechanical manufacturing industry.

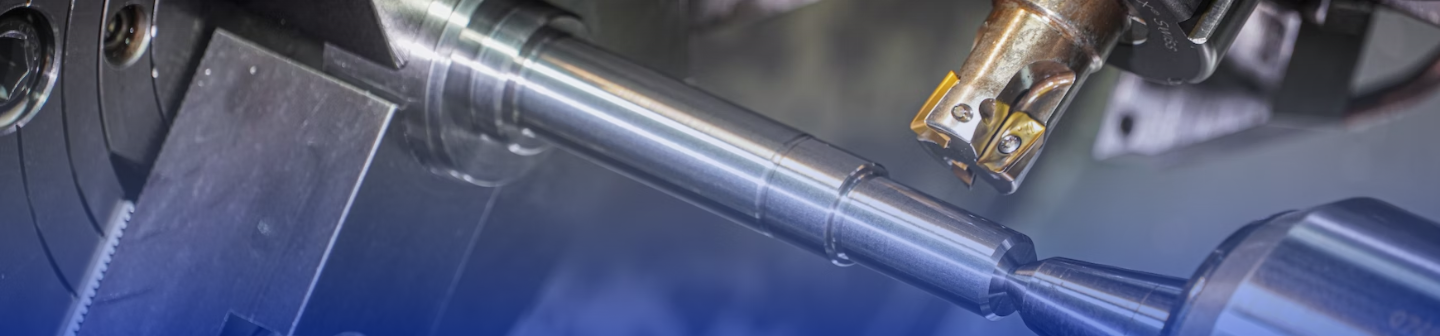

Discussion on CNC Milling Tool Technology in Mold Manufacturing

CNC milling tool technology in mold manufacturing is one of the key elements driving the high-quality development of the mold industry. With the transformation and upgrading of the manufacturing industry and the continuous advancement of smart manufacturing technology, CNC milling tool technology is evolving toward greater efficiency, precision, and environmental friendliness. With the rapid development of manufacturing and the rise of smart manufacturing, the mold manufacturing industry is facing unprecedented opportunities and challenges.

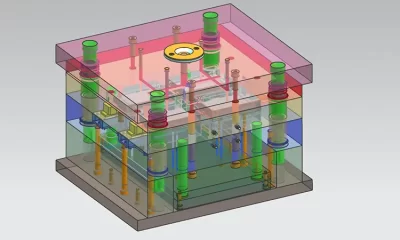

Innovative Design of Side Core Pulling Mechanism for Injection Molds

During injection molding, when the side walls of the plastic part feature holes, grooves, or protrusions (i.e., undercuts), it is necessary to ensure that the side-molded components are extracted before demolding.

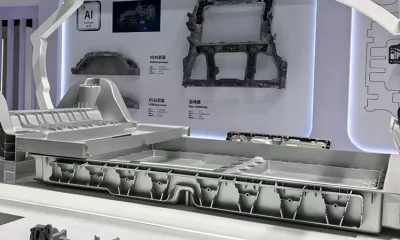

How to Planning a Large Integrated Die Casting Workshop?

With the rapid development of global manufacturing and increasingly fierce market competition, large monoblock die-cast parts have been widely used in the new energy vehicle field due to their advantages of reducing the number of parts, improving structural strength, and reducing production processes.

Bending Design for Precision Stamping Dies

Focusing on the bending design of precision stamping dies, this paper discusses bending design concepts, including process analysis and sequence arrangement; introduces bending process requirements, such as bending radius, straight edge length, and direction; introduces the standard structure of precision bending dies and various bending techniques, emphasizing the importance of reasonable design in ensuring part quality and reducing costs.

Intelligentization Emerges as Key Trend in Sheet Metal Processing Technology

Sheet metal processing technology, as an important part of the manufacturing industry, is widely used in fields such as automobiles, electronics, construction, and home appliances.