Blog

More to learn about rapid prototyping and manufacturing industry.

How to Improve Efficiency in High-End Mold Manufacturing and Precision Machining?

With the rapid development of global manufacturing, the demand for high-end molds and precision machinery continues to grow. Their processing efficiency directly impacts corporate competitiveness and market responsiveness.

Deformation Control Strategy for Turning Thin-Walled Ring Components Made of High-Temperature Alloys

Nickel-based high-temperature alloys, exemplified by GH4169, typically exhibit a hardness of 346–450 HBW.

Machining Processes for Lathe Supports and Fixture Design Analysis

Machining lathe supports is a complex process requiring multiple stages such as rough machining and finish machining to complete.

Study on undercut Performance of Special Threaded Water-Tight Casing

The commonly used specifications for special threaded water-stop casings in the Five Seas region currently range from 18“ to 44”, with 20“, 24”, 30“, and 36” casings being the most widely applicable and in highest demand.

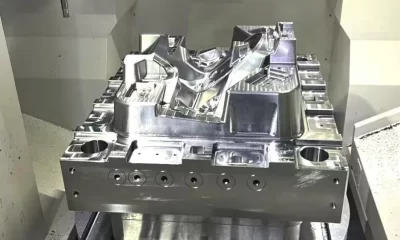

Large Precision Injection Mold Design for New Energy Vehicle Rearview Mirror Inner Bracket

As one of the most critical exterior components of an automobile, the rearview mirror demands exceptionally high aesthetic standards.

Research on Machining Processes for Complex Spatial Components

In modern manufacturing, with the rapid advancement of technology and ever-increasing demands for product performance, the application of spatially complex parts has become increasingly widespread.

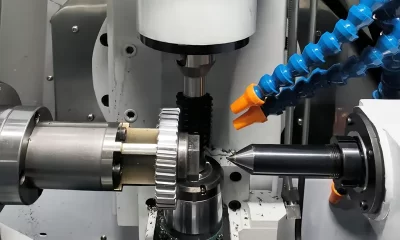

Compensation for Machining Errors in CNC Gear Hobbing Machines

Error compensation is essential in CNC machine tools, where errors can be categorized by origin into internal and external types, and by characteristics into random, time-varying, and deterministic types.

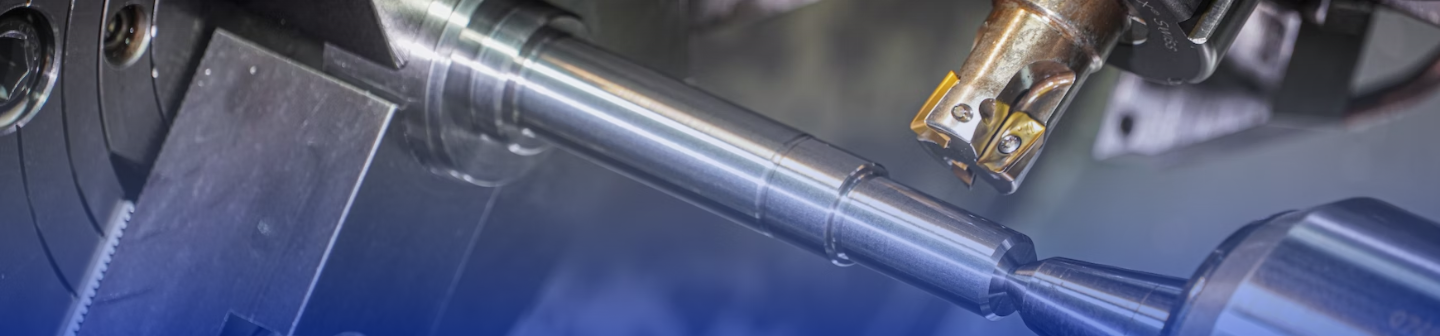

Advancements in Precision Machining: Key Technologies Driving Modern Mechanical Manufacturing

The advancement of mechanical manufacturing processes serves as the core driving force behind industrial modernization. Through the convergence of materials science, information technology, and equipment technology, precision machining techniques have progressively overcome the limitations of traditional processes.

The Evolution of Metal-Cutting Tools: From Traditional Materials to Intelligent Manufacturing

Early metal cutting operations were constrained by materials and processes, resulting in poor tool durability and low machining efficiency, which severely hindered industrial production progress.

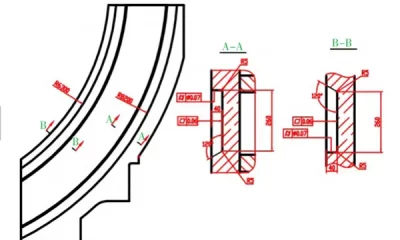

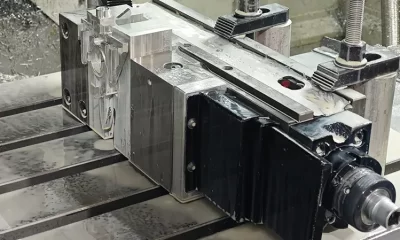

Research on Large ARC Machining Technology

The test section of a certain project consists of four large guide rail seats, symmetrical in upper and lower halves on both sides. They are bolted and fixed to the frame of the support section.

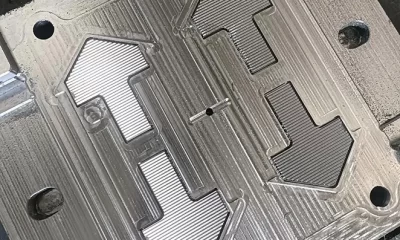

Research on Complex Mold Processing Technology Based on Five Axis CNC Machine Tool

As the manufacturing industry increasingly demands high-precision, complex-shaped molds, traditional CNC technology faces numerous challenges in processing intricate molds.

Technical Measures for Machining Multi-Faced Parts on CNC Milling Machines

As manufacturing advances toward higher precision and efficiency, the machining quality and productivity of multi-faceted parts are receiving increasing attention.