Blog

More to learn about rapid prototyping and manufacturing industry.

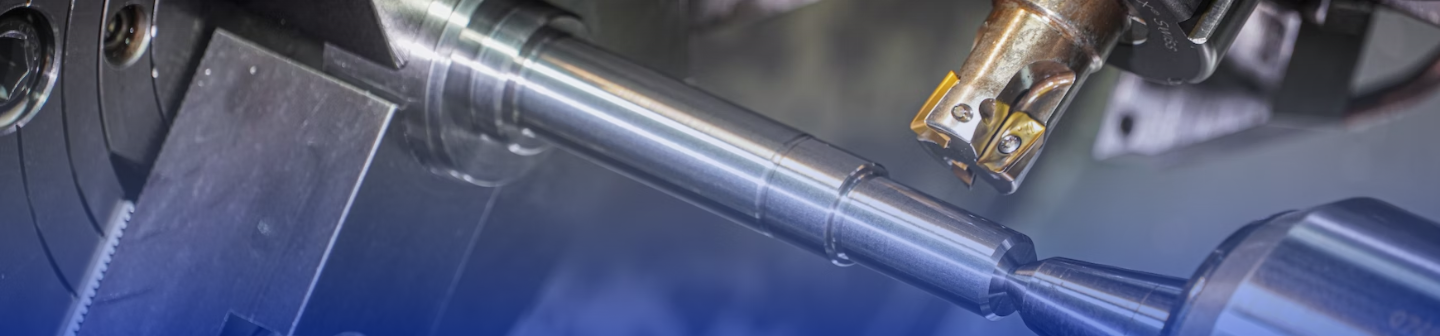

Research on Allowance Allocation Technology for a Specific Crankshaft Turning-Milling Composite Process

As the automotive industry advances toward greater mechanical automation, modularization, and component precision, the design philosophy and standards for automotive engines and parts continue to evolve annually.

Design and Exploration of Snap-Fit Structures in Plastic Packaging

Due to material and manufacturing constraints or structural and functional requirements, a complete plastic packaging unit is typically divided into multiple components for separate production.

Quality Control and Technological Innovation in the Manufacturing of Large-Scale Thin-Walled Stainless Steel Heat Exchangers

With the rapid development of the chemical industry, the performance and manufacturing quality of heat exchangers have become key indicators for evaluating equipment standards.

Precise Fabrication of Micro-Blind Hole on Thin-walled Parts by Electrical Discharging Machining

With the advancement of microelectronics and micromechanics, the demand for machining minute features on components has grown significantly, placing higher demands on micro-feature machining technologies.

How Cutting Equipment Processes Inspire Smarter Sheet Metal Design?

Upgrading sheet metal processes by updating equipment is a common approach adopted by many enterprises today. However, within just a few short years, sheet metal equipment has entered a stagnation phase. It is boldly predicted that over the next several years or even decades, sheet metal equipment may not undergo significant changes.

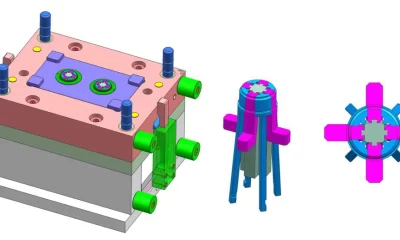

Design of Injection Molds for Electrical Outlet Housings

With the rapid development of the global economy, the power industry has also achieved remarkable progress. The widespread application of electrical equipment has effectively promoted the reform and improvement of power mechanisms.

Study on the Performance Differences Between NylonPA66 and PA6T Materials

Polyamide (nylon), as a crucial class of synthetic polymer materials, possesses outstanding mechanical properties, wear resistance, and ease of processing, occupying a significant position in modern industry.

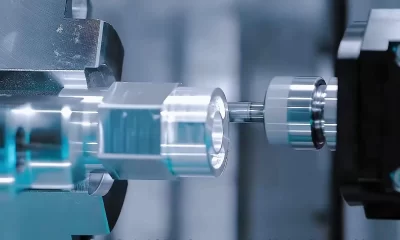

Measurement Method for Cone Taper Using a Roundness Tester and Uncertainty Analysis

Taper, as a critical dimension in the mechanical processing industry, demands increasingly higher standards for measurement efficiency, accuracy, and range as advanced manufacturing continues to evolve.

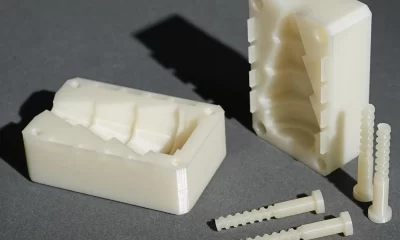

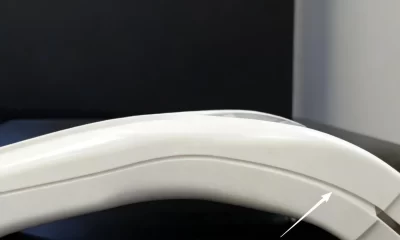

Approaches to Resolving Injection Mark Defects in Plastic Parts

Plastic injection molding is a manufacturing process widely used across industries to produce plastic components. This process involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, and then ejecting the finished part.

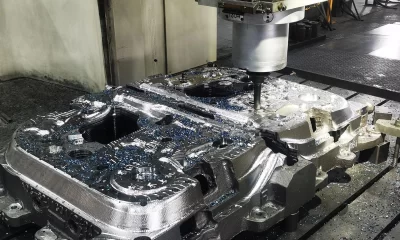

Research on CNC-Material Collaborative Control Mechanism for Surface Quality of Mechanical Molds

As mold materials evolve toward high-hardness, high-strength specialty alloys, the thermal-mechanical response complexity during CNC machining has significantly increased, making it challenging for traditional control methods to consistently achieve stable surface quality.

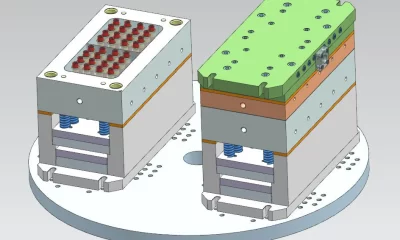

Rotary Turntable Structure Design for Dual-Color Injection Molds

The modern automotive industry as a whole is moving toward lightweighting. Currently, injection molding is a mature production technology, typically performed using injection molding machines.

Investigation into the Influence of Temperature on the Machining Accuracy of CNC Machining Center Spindles

In the manufacturing process of components, machining accuracy is of paramount importance. As the primary processing equipment, the machining precision of CNC machine tools directly impacts the accuracy grade of finished parts.