China CNC Milling » Blog » Milling Machining Methods, Strategies, and Formulas

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Milling machining encompasses a diverse range of methods and strategies. These range from basic operations like face milling and slot milling to advanced techniques such as high-speed, high-performance, and micro-machining.

Each strategy is designed to optimize specific aspects of the machining process, including material removal rate, surface finish, tool life, and workpiece precision.

By understanding the characteristics of different tools, machine requirements, and application scopes, manufacturers can select appropriate milling strategies.

This enables them to achieve efficient, accurate, and high-quality machining outcomes across a variety of materials and production scales.

Milling Machining Methods

Basic Milling Operations

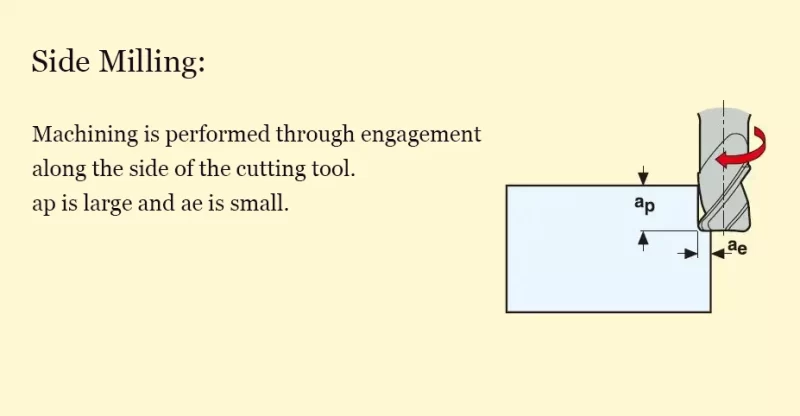

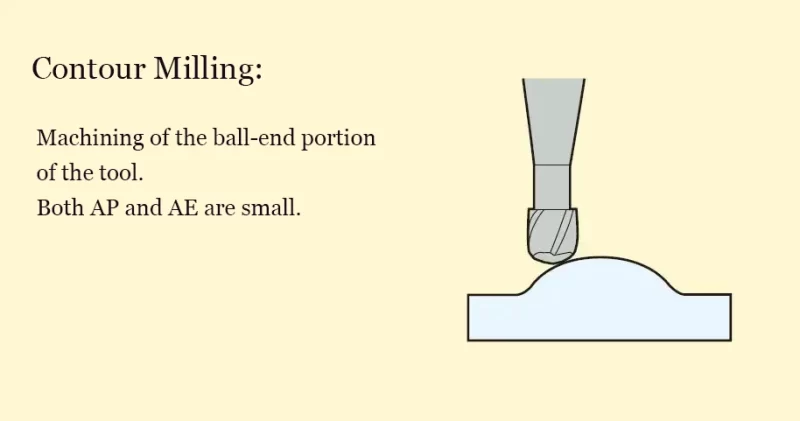

Includes: Face milling, slot milling, side milling, and contour milling.

-800x416.webp)

Advanced Milling Operations

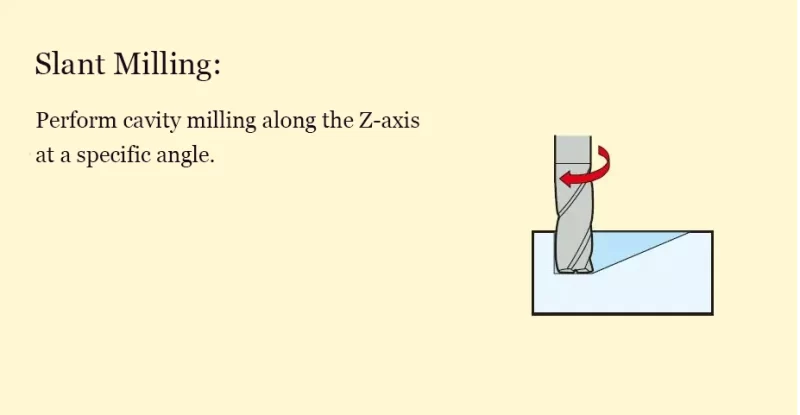

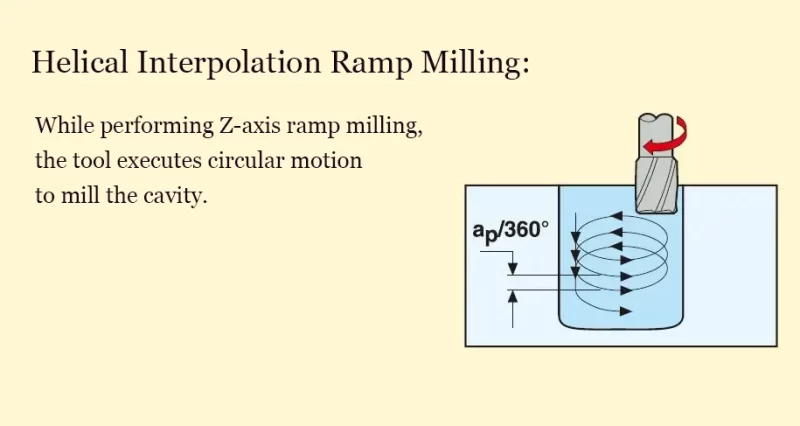

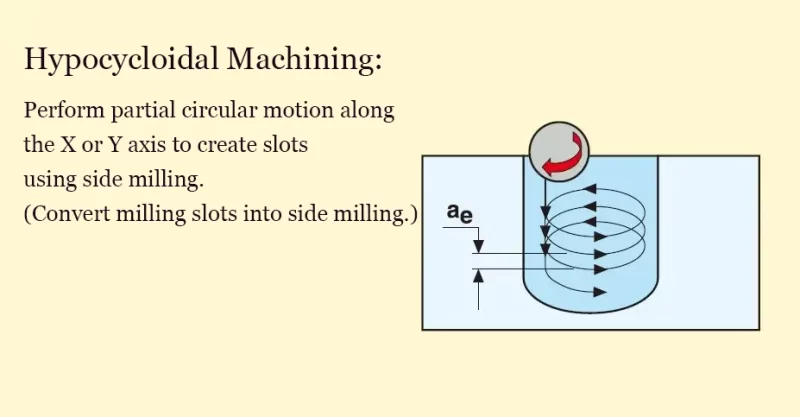

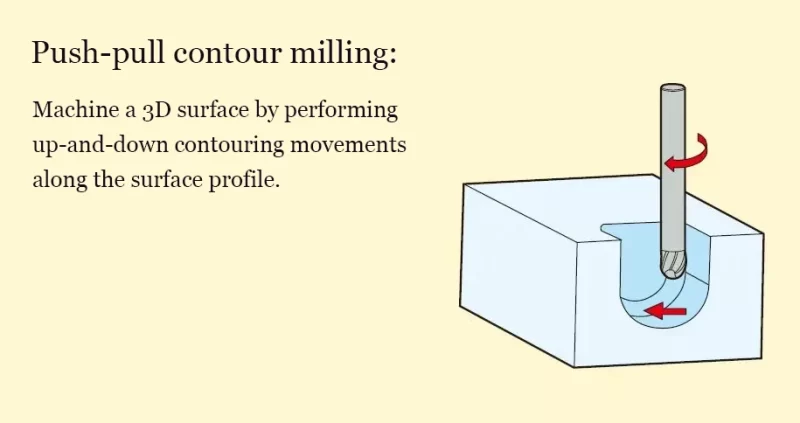

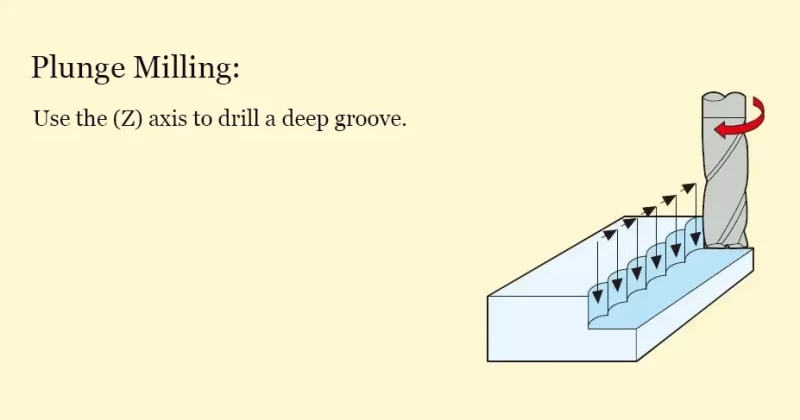

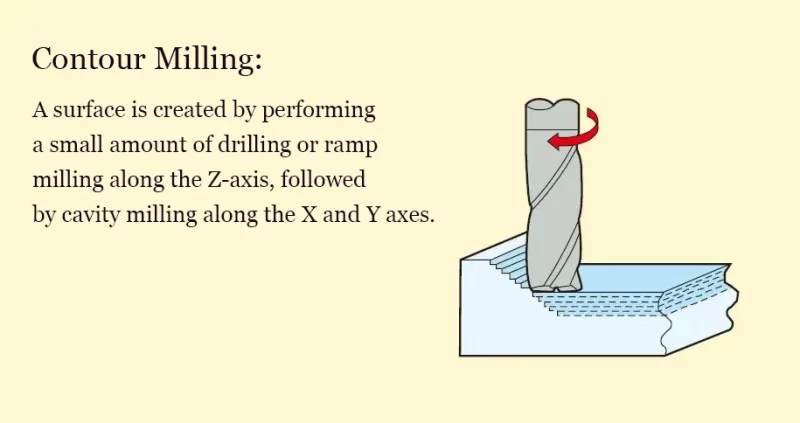

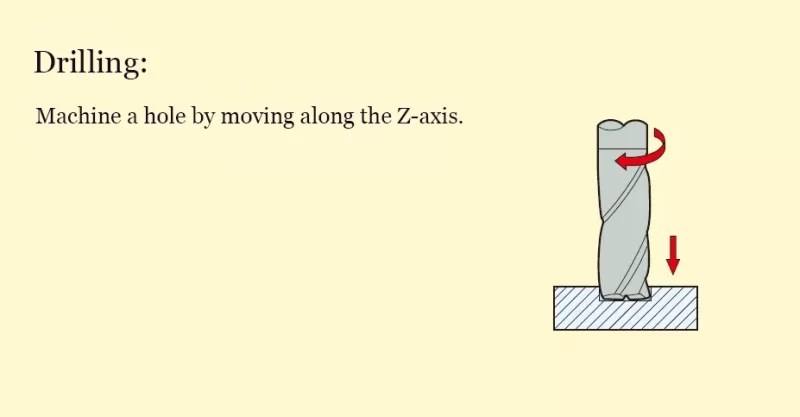

Includes: ramp milling, thread interpolation, cycloidal milling, push-pull contour milling, slot milling, contour milling, and drilling.

Definition of Milling Machining Strategy

General Machining

This is a general-purpose machining strategy. The ratio of cutting width to cutting depth may vary depending on the type of operation.

1) Tool Characteristics: The tool features relatively long cutting edges and a smaller core diameter, with no stringent precision requirements.

2) Machine Requirements: No special requirements.

3) Application Scope:Features basic CNC technology, so advanced machining methods with high difficulty are not feasible.

Metal removal rates can only reach general levels.

Application areas typically include small batch production scales and a wide range of materials.

High-Speed Machining

It is a machining strategy combining small radial cutting depths with high cutting speeds and feed rates.

Depending on the method employed, it can achieve very high material removal rates and low Ra values.

This strategy is characterized by low cutting forces and minimal heat transfer to the tool and workpiece.

It also reduces burr formation and ensures high dimensional accuracy of the workpiece.

High-speed machining employs faster cutting speeds than conventional methods to achieve high metal removal rates and excellent surface roughness.

1) Tool characteristics: Stable (larger core diameter and shorter cutting length), with clear and well-formed chip clearance zones that facilitate efficient chip evacuation and coating retention.

2) Machine Requirements: High-speed CNC control, high spindle speed, and rapid table feed rates.

3) Application Areas: Semi-finishing and finishing of hardened steel (48–62 HRC) in the mold industry with short delivery times.

When employing the correct tools and advanced machining methods, this technology can also be applied to numerous other materials.

High-Performance Machining

It is a machining strategy capable of achieving exceptionally high metal removal rates.

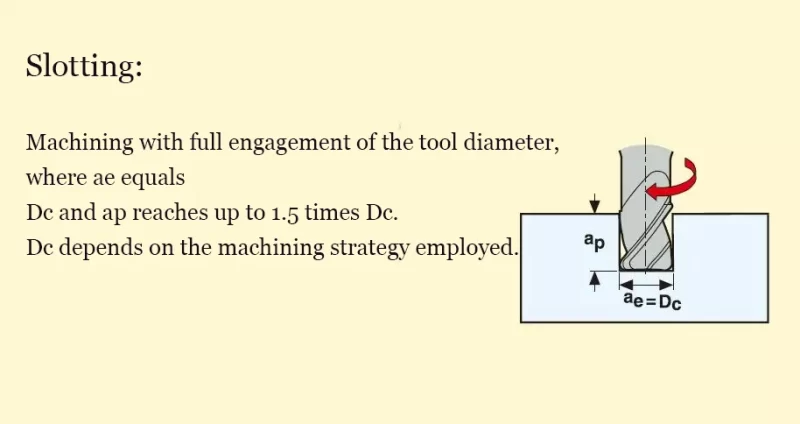

This strategy is characterized by a cutting width equal to 1 times Dc and a cutting depth ranging from 1 to 1.5 times Dc, depending on the workpiece material.

Under high-performance machining, significantly higher chip loads than conventional machining are employed to achieve extremely high metal removal rates.

1) Tool Characteristics:Specially developed chip-breaking structures are applied on tool flutes.

Tool tips are protected by 45° angles, small flats, or rounded shapes.

The chip-breaking zones are exceptionally smooth.

Tools may have coatings and can come with or without side clamping shanks.

2) Machine Requirements: High stability, high power capacity, and a rigid clamping system.

3) Applications: Mass production where productivity is critical, or single-piece machining demanding high metal removal rates.

High Feed Machining

is a high-feed machining strategy combining full-diameter cutting with small cutting depths.

Under high feed machining, higher metal removal rates and good surface roughness can be achieved by employing faster feed rates than conventional machining.

1) Tool Characteristics: Specially developed cutting edges, extremely short cutting lengths, and coatings.

2) Machine Requirements: High stability, capability for high feed rates.

3) Application Areas:

From mild steel to hardened steel, titanium alloys, and stainless steel, it excels as a pre-machining process before high-speed machining.

It is also suitable for deep cavity machining.

One advantage of this technology is its user-friendly implementation in CAM for simple, safe, and rapid programming.

Using the so-called contour milling strategy, complex shapes can be programmed relatively easily without extensive programming experience.

Micro-machining

It is a machining strategy employing tools with extremely small diameters.

1) Tool characteristics: Diameter range from φ0.1 to 2.0 mm, short cutting length, wide range of outer diameter reduction, high precision, coated.

2) Machine tool requirements: High spindle accuracy, high spindle speed, CNC capability, thermal stability to prevent spindle elongation.

3) Application areas: Machining various cavities in numerous material types.

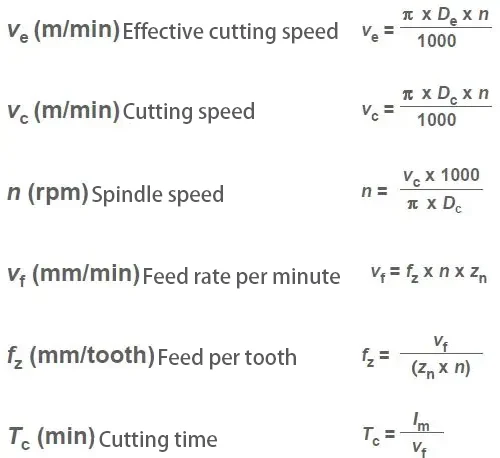

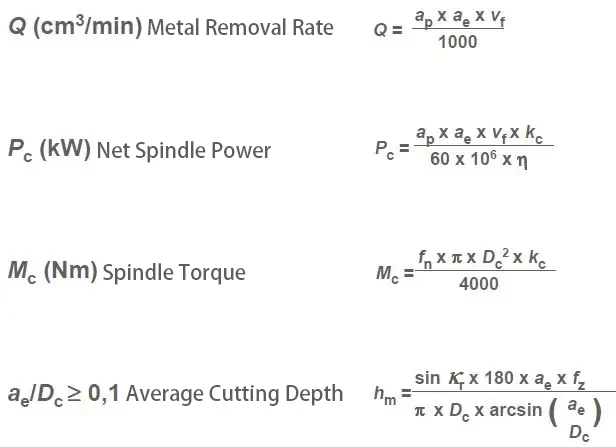

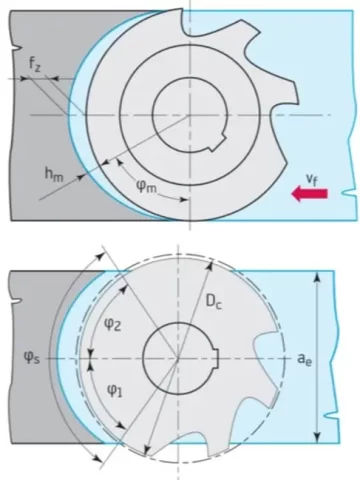

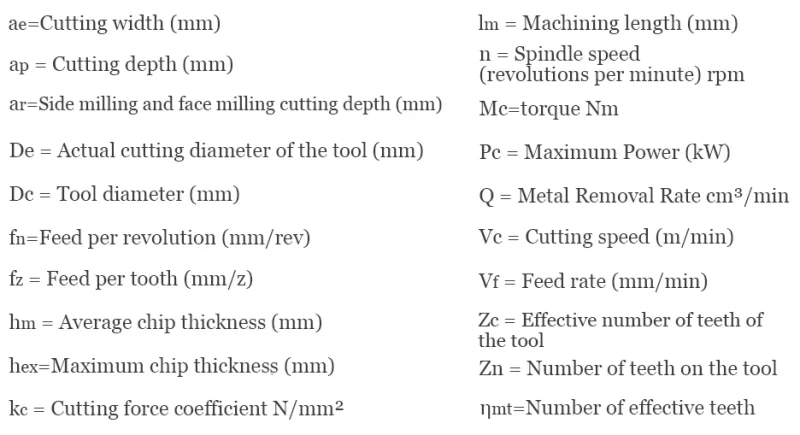

Milling Parameters and Calculation Formulas

Cutting parameter calculation formula:

Milling Summary

1) Verify the machine tool’s power and rigidity to ensure the selected milling cutter diameter minimizes tool overhang within the machine’s specifications;

2) Maintain an appropriate number of teeth on the milling cutter to prevent excessive simultaneous engagement of cutting edges with the workpiece, which can cause vibration.

Ensure sufficient cutting edge engagement when milling narrow workpieces or cavities;

3) Apply an appropriate feed per tooth to achieve optimal cutting performance with sufficiently thick chips, thereby reducing tool wear.

Use positive rake angle inserts to ensure smooth cutting and minimize power consumption;

4) Select a milling cutter diameter suitable for the workpiece width;

5) Maintain the correct main rake angle (45 degrees is suitable for general milling);

6) Proper tool positioning;

7) Use cutting fluid only when necessary; dry milling typically yields longer tool life.

Conclusion

Effective milling requires careful consideration of machining methods, strategies, and parameters.

Selecting the right combination of tool, cutting conditions, and milling strategy ensures optimal material removal.

It also minimizes tool wear and achieves precise surface finishes.

Whether performing general, high-speed, high-feed, high-performance, or micro-machining, maintaining proper tool positioning is essential.

It is also important to ensure an appropriate feed per tooth and suitable cutter engagement.

By integrating these principles, manufacturers can maximize productivity and enhance machining accuracy.

They can also extend tool life, supporting both small-batch and mass-production requirements.