Capable Machining

Mastering the Art of Precision Machining: CNC Milling and CNC Lathe Compared

China CNC Milling » Blog » Mastering the Art of Precision Machining: CNC Milling and CNC Lathe Compared

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

CNC milling and CNC lathe are two different machining processes that are used to create different types of parts.

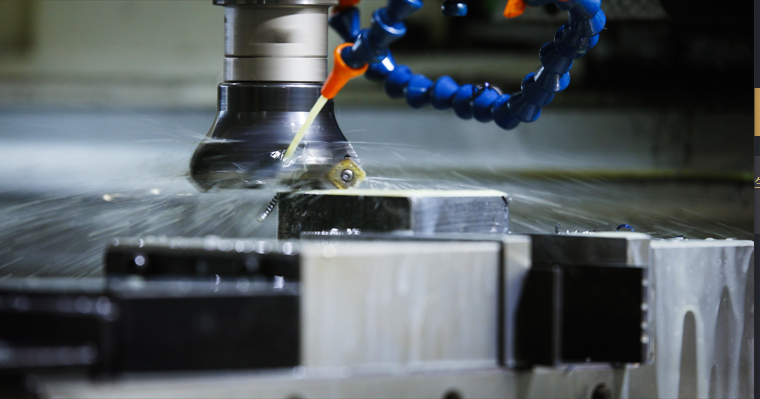

Milling is a machining process that uses a tool to remove material from a solid block or billet of material. The tool rotates at high speeds and can be programmed to move along multiple axes to create complex shapes and contours. The milling process can be used to create parts such as gears, brackets, and housings.

CNC milling and CNC lathe are both machining processes that use computer numerical control systems to automate the cutting of raw material. However, there are some fundamental differences between the two processes in terms of their mechanics and application.

1. Configuration:

CNC milling is a horizontal or vertical milling machine that uses a rotating cutting tool to remove material from a stationary workpiece. CNC lathe, on the other hand, uses a rotating workpiece and a stationary cutting tool to create round parts.

2. Material:

Milling is best for cutting a wide range of material like metal, plastic, wood, etc. Meanwhile, CNC lathe is suitable for cutting round or cylindrical objects like shafts and bolts.

3. Operation:

Milling is often used to create complex shapes like custom parts or prototypes, where customers can take advantage of the high degree of accuracy and repeatability of the machine. CNC lathe is often used in the production of products, especially when turning or grooving operations are involved.

4. Cutting Process:

CNC milling machines use different types of cutting tools like end mills, drills, and broaches to cut material. CNC lathes have boring bars, drills, and threading tools to cut round shapes.

5. Machining Types:

CNC milling can perform various machining types like drilling, milling, and reaming. CNC lathes can perform turning, boring, and facing operations.CNC lathe, on the other hand, is a machining process that uses a tool to rotate a workpiece and remove material from the outer diameter. The tool is typically stationary and moves along the length of the workpiece to create cylindrical shapes such as shafts and spindles.

In summary, the main difference between CNC milling and CNC lathe is the type of machining operation performed – milling removes material from a block or billet whereas lathe removes material from the outside of a cylindrical workpiece.