China CNC Milling » Blog » Magnesium vs. Aluminum Alloys: Performance in EV Drive Housings

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

New energy vehicles have emerged as a new engine for the global economy. However, the integration of power batteries and electric drive systems typically adds 200–500 kg to the vehicle’s weight.

This increase is in comparison to conventional gasoline vehicles of the same class. The added weight leads to reduced range and handling.

This creates an urgent need for lightweight solutions. As a critical component, reducing the weight of the electric drive system housing is crucial for overall vehicle weight reduction.

Magnesium vs. Aluminum Alloys

Magnesium alloys offer approximately one-third lower density than aluminum alloys. They have established applications in the internal combustion engine vehicle sector.

Manufacturers like General Motors and Ford have successfully employed magnesium alloys in transmission housings to achieve weight reduction.

In the field of new energy electric drive housings, magnesium prices are trending downward and stabilizing.

As a result, the substitution of magnesium alloys for aluminum alloys has garnered significant industry attention.

Currently, aluminum alloy die-cast components have long dominated automotive castings.

The ADC12 alloy is widely used in parts such as motor housings due to its excellent casting properties and cost advantages.

Thin Bing et al. systematically characterized the mechanical properties of ADC12 steering gear housings.

They also examined the relationship between die-casting processes and microstructure.

Advances

Although magnesium alloys can adopt aluminum die-casting processes, thixomolding is emerging as the preferred technology for large structural components.

This approach helps balance safety, environmental considerations, oxidation losses, and high density requirements.

Gu et al. noted that the solid phase fraction significantly impacts forming capability and defect formation in thixomolding.

An appropriate solid phase distribution enhances the properties of magnesium alloys.

Okayasu et al. compared cold-chamber die casting, hot-chamber die casting, and thixomolding for thin-walled components.

They confirmed that thixomolding delivers the optimal microstructure and properties.

However, existing studies primarily rely on standard specimens or thin-walled components.

They lack in-situ sampling and systematic comparisons for thick-walled structures such as electric drive housings.

Therefore, this study systematically compares the microstructure, mechanical properties, and corrosion resistance of identical electric drive housings.

Manufacturers produce these housings using magnesium alloy thixomolding and aluminum alloy high-pressure die casting.

The findings provide practical guidance for the application of magnesium alloys in electric drive housings.

Test Materials and Methods

The test materials were commercial aluminum alloy ADC12 and magnesium alloy AZ91D.

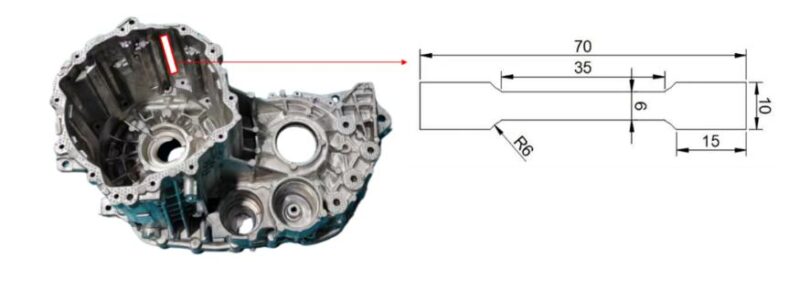

Specimens for analysis were taken from an electric drive housing casting used in a new energy vehicle, as shown in Figure 1.

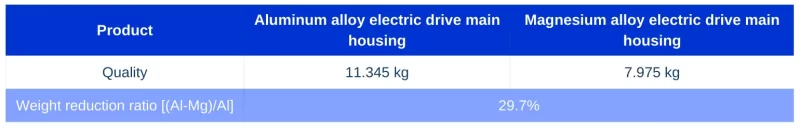

Manufacturers produced the aluminum housing via high-pressure die casting, measuring its mass at 11.345 kg.

The added weight leads to reduced range and handling.

Under identical structural conditions, the magnesium alloy achieved a significant 29.7% weight reduction compared to the aluminum alloy.

The location for in-situ sampling analysis on the electric drive housing is shown in Figure 2, where the wall thickness is 10 mm.

Aluminum alloy metallographic specimens underwent mechanical polishing and etching with a 5% HF solution.

Researchers etched the magnesium alloy specimens using an alcoholic nitric acid solution and then observed them under an optical microscope.

Using IPP (Image Pro Plus) image analysis software, researchers quantitatively analyzed the solid phase fraction in the semi-solid state microstructure.

Researchers conducted room-temperature tensile tests on specimens conforming to GB/T 228.1-2021 standards.

These tests used an MTS universal testing machine at a tensile rate of 1 mm/min.

Neutral salt spray testing employed continuous spraying with a 5 wt.% NaCl solution at a salt concentration of 50 g/L, pH 6.8, and a salt spray chamber temperature of 35°C.

Microstructure

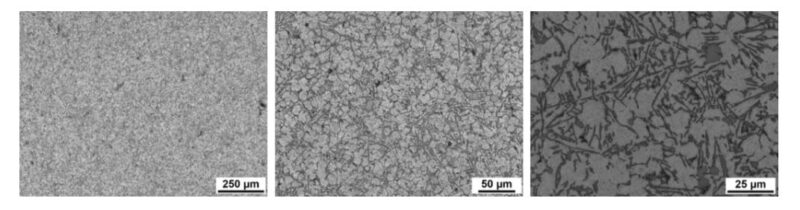

Researchers directly extracted specimens from the electric drive housing bodies to clarify the microstructural differences between the two materials in thick-walled housings.

These specimens were then used for microstructural examination.

Figure 3 shows the metallographic structure of high-pressure die-cast ADC12 aluminum alloy, revealing a small number of microporous defects within the structure.

The ADC12 aluminum alloy primarily consists of α-Al, Si, and Al₂Cu phases.

In the aluminum, the grains exhibit dendritic morphology.

Under the influence of high pressure and rapid cooling during die casting, grain refinement and secondary phase refinement occur to some extent.

However, needle-like eutectic silicon or AlFeSi phases are randomly distributed along the dendrites.

This disrupts the continuity of the matrix, adversely affecting strength and ductility.

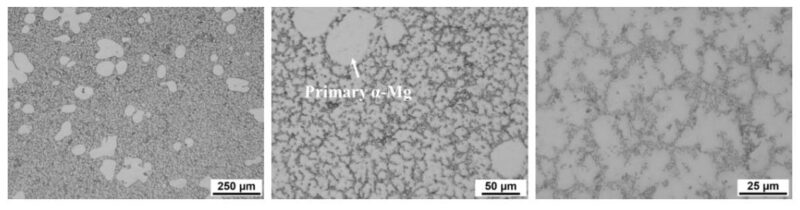

Figure 4 shows the metallographic microstructure of AZ91D magnesium alloy cast by semi-solid injection molding, exhibiting typical semi-solid morphology.

The structure contains near-spherical primary solid phases uniformly distributed within the residual liquid phase solidification structure.

Measurements indicate that the solid phase fraction is 10.5%.

Continuous network-like Mg₁₇Al₁₂ precipitation phases are visible at grain boundaries.

Benefiting from the laminar flow filling characteristics of semi-solid casting, the internal structure of thick-walled components is dense.

Inspection revealed no voids, shrinkage porosity, or hot cracks.

This fine, uniform microstructure with minimal defects provides the foundation for the alloy’s excellent corrosion resistance.

Mechanical Properties

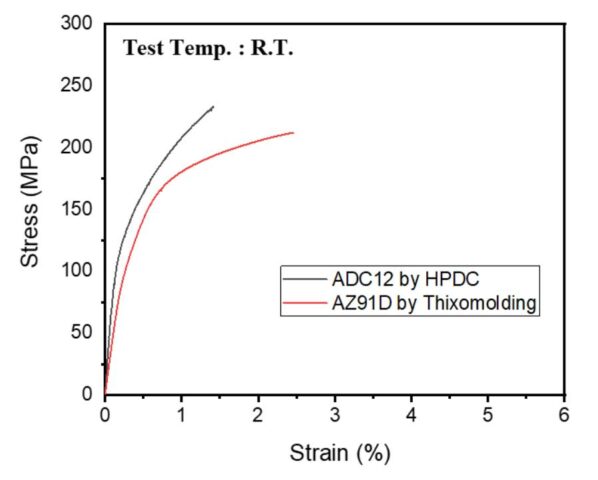

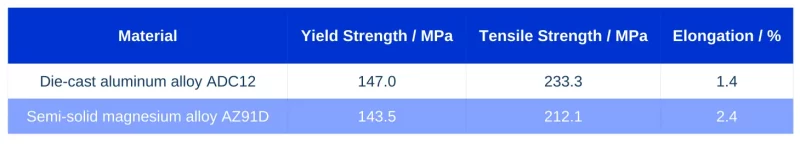

Figure 5 and Table 2 present the tensile test curves and corresponding mechanical properties.

The samples were taken from the main bodies of the two electric drive housings.

It is evident that both die-cast aluminum alloy and semi-solid magnesium alloy exhibit diminished properties in thick-walled conditions.

This degradation primarily stems from reduced solidification rates, which lead to coarse microstructures.

As a result, the coarse microstructure reduces grain refinement and weakens second-phase strengthening effects.

Specifically: In terms of tensile strength, ADC12 demonstrated superiority with pronounced work-hardening effects.

However, the semi-solid AZ91D exhibited superior elongation, achieving 2.4% even in thick-walled samples.

This indicates that the microstructural uniformity and defect suppression achieved through semi-solid forming significantly enhance plasticity.

Considering both yield strength and elongation, the semi-solid AZ91D possesses the potential to replace ADC12.

Corrosion Performance

Magnesium alloys are generally considered to have inferior corrosion resistance compared to aluminum alloys.

Both alloy composition and microstructural state fundamentally govern corrosion behavior.

When aluminum alloys contain higher levels of Cu, Fe, and other elements, their corrosion resistance also significantly decreases.

Researchers conducted neutral salt spray (NSS) tests to objectively evaluate the in-service corrosion resistance of both housing materials.

For the tests, researchers prepared uncoated specimens by uniformly sanding them to bare metal using sandpaper.

Results are shown in Figure 6.

After 24 hours of salt spray exposure, the die-cast ADC12 aluminum alloy developed significant corrosion, and its metallic luster completely disappeared.

In contrast, the semi-solid AZ91D specimen remained intact and retained its metallic sheen.

After 72 hours of salt spray, extensive corrosion products covered the aluminum alloy surface.

In contrast, the magnesium alloy only exhibited darkening of the surface color without noticeable corrosion products.

After 168 hours of salt spray exposure, the corrosion of the die-cast ADC12 aluminum alloy continued to deepen, with thickening of the corrosion product layer.

In contrast, the semi-solid AZ91D magnesium alloy exhibited only minor localized corrosion, maintaining good macroscopic integrity.

The average corrosion rates measured by the weight loss method are listed in Table 3.

Measurements showed that the corrosion rate of the die-cast ADC12 aluminum alloy was 0.546 mm/y, while the semi-solid AZ91D magnesium alloy exhibited a rate of 0.325 mm/y.

The results indicate that the neutral salt spray corrosion resistance of the semi-solid AZ91D magnesium alloy in the thick-walled electric drive housing matches that of the ADC12 aluminum alloy.

Additionally, it exhibits a lower corrosion rate and superior surface integrity.

Figure 6 Appearance of the neutral salt spray test on the main body sample taken from the electric drive housing

Conclusion

This study compared the microstructure, mechanical properties, and corrosion resistance of high-pressure die-cast ADC12 aluminum alloy and semi-solid injection-molded AZ91D magnesium alloy.

Researchers conducted the comparison using identical structural electric drive housings.

Key findings are as follows:

(1) The microstructures of die-cast aluminum alloy and semi-solid magnesium alloy exhibit distinct differences.

Die-cast ADC12 displays dendritic morphology with abundant acicular silicon and other secondary phases.

In contrast, semi-solid AZ91D magnesium alloy contains near-spherical primary solid phases, with continuous network-like Mg₁₇Al₁₂ precipitates visible at grain boundaries.

The microstructure in thick-walled sections is dense, showing no significant defects.

(2) Regarding mechanical properties of samples taken from the electric drive housing body, both materials exhibit reduced standard values in thick-walled conditions.

Overall, the yield strength of the semi-solid AZ91D magnesium alloy closely matches that of die-cast ADC12 aluminum alloy, with slightly superior elongation.

However, ADC12 demonstrates superior tensile strength.

(3)Regarding corrosion resistance of samples from the electric drive housing body, the semi-solid AZ91D magnesium alloy outperformed the die-cast ADC12 aluminum alloy.

Neutral salt spray testing revealed this behavior.

The bare die-cast ADC12 aluminum alloy exhibited noticeable corrosion products on its surface after just 24 hours of salt spray exposure.

In contrast, the bare semi-solid AZ91D magnesium alloy sample retained its surface integrity without extensive corrosion even after 168 hours of salt spray exposure.