China CNC Milling » Blog » Introduction to the artillery body tube machining process

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

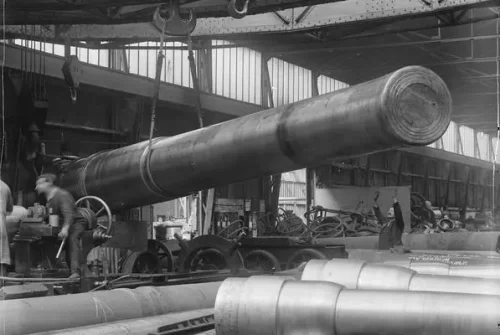

The history of artillery bodies dates back to the early use of cannons in the 14th century, when metal tubes were mounted on wooden carriages to hurl projectiles across the battlefield.

As warfare evolved, so did the design and construction of artillery bodies—shifting from rudimentary bronze and iron barrels to more sophisticated steel structures with enhanced range, accuracy, and durability.

By the 19th and 20th centuries, industrial advances enabled mass production of field guns, howitzers, and self-propelled artillery systems, all featuring reinforced gun bodies capable of withstanding immense explosive forces.

Modern artillery bodies are now precision-engineered using advanced metallurgy and computer-aided design, reflecting centuries of continuous innovation in both military tactics and mechanical engineering.

Artillery is known as the “god of war”, the role played in the war can not be underestimated. In the complex artillery system, the gun body is the most important part.

The gun body consists of the body tube, tail, bolt and other components, of which the body tube is the most important.

The body tube gives the most important combat performance to the artillery, which is the main body of generating the combat power of the artillery.

Therefore, in-depth study of artillery body tube, combing all aspects of the development of the body tube technology to improve the performance of artillery, has a very important significance.

Body tube material

High rifling pressure artillery on the strength and toughness of the bore has extremely high requirements, the body tube processing of the first problem is the choice of materials and smelting.

Early artillery was mainly cast from bronze, iron, and other metals. With the invention of the converter steelmaking method in the second half of the 19th century, artillery began to be made with large cast-steel bodies. Soon after, high-strength alloy steel was developed for manufacturing the gun bodies..

Electroslag remelting was developed to refine alloy steel for artillery bodies. This process refines special steel, and during electroslag remelting, small amounts of sulfur, phosphorus, and other harmful elements can be removed.

Eliminating these impurities improves the strength and toughness of the artillery, making the steel purer and better suited for manufacturing gun barrels.

Modern artillery body tube materials are used in alloy steel, often in carbon nickel-chromium-platinum-based alloy steel, but also a small amount of vanadium to do modified steel.

In this paper, the development status of artillery body tube processing technology is discussed. Traditional processing technologies for body tubes are introduced, and the latest progress abroad is analyzed.

The aim is to help promote the development of domestic production in related industries.

Body tube machining process

Deep hole machining

In machining, holes with a length-to-diameter ratio greater than 10 are classified as deep-hole machining. In modern artillery, such as howitzers, tank guns, and anti-tank guns, the body tube length is generally 30 to 55 times the caliber.

For small-caliber anti-aircraft guns, the body tube length can reach around 100 times the caliber. These all fall under the category of “deep-hole machining,” which is highly challenging to process.

The difficulty of deep hole machining is “deep”.

In the process of machining, the operator can not observe the cutting process, but also need to ensure a high degree of accuracy, and long and thin pipe in the process of machining is very prone to bending and deformation, so it is extremely difficult.

Deep hole machining of forged pipe blanks requires the use of special drills and drilling tools such as deep hole drills.

In order to ensure the dimensional accuracy and surface finish of the drilled holes, grinding and other fine processing is indispensable, so there should be suitable for various types of gun barrels of the grinding tool.

Machine tools for deep hole machining are very complex special machine tools, the processing of the barrel bore can reach a high degree of precision, is the artillery processing tool.

Self-tightening process

Most of the high rifling pressure guns use self-tightening body tube. Self-tightening process is in the boring diameter to basically meet the requirements, that is, the bore semi-finishing process.

Self-tightening is a special process applied to an ordinary single-barrel body tube. In this process, the barrel undergoes controlled plastic deformation from the inside out.

As a result, the outer layer of the body tube exerts pressure on the inner layer. During firing, this increases the pressure-bearing capacity of the body tube. Consequently, the required thickness of the tube can be reduced, which in turn lowers the overall weight of the artillery.

Due to the self-tightening, the compression prestress of the inner layer can prevent the expansion of fatigue cracks and increase the fatigue life.

- Historical Development

After the 1960s, the self-tightening technology of body tube has matured and received real attention. The British L7 105mm tank gun was the first to adopt the body tube self-tensioning technology.

After that, the main guns of German Panther I and American M60 tanks generally began to adopt the self-tightening process of body tube. Nowadays, this technology is adopted in the manufacturing process of tank guns and anti-tank guns.

In China, the self-tightening of body tubes has been used in the production of artillery since the mid-1970s. 105 mm tank guns of Type 83, 120 mm anti-tank guns of Type 89, and 125 mm tank guns use self-tightening of body tubes.

The methods of applying pressure in the self-tightening process include the water-pressure method, the bar-pressure method and the air-pressure method.

By utilizing ultra-high hydraulic presses, it is possible to produce ultra-high-pressure body tubes that can withstand 10,000 standard atmospheres.

After the self-tightening treatment of the body tube, its inner and outer diameters and then subjected to mechanical processing, part of the stress is eliminated, followed by expansion and contraction.

Therefore, a lot of effort is required in the processing procedure and processing method.

Rifling

After the self-tightening process is completed, the rifling is made. Rifling is a special processing method.

Need to use the drill repeatedly processing dozens of times, in order to achieve the required depth of the rifling.

In the use of tools, with mechanical adjustment of the tool feed, feed every increase in the amount of rifling, until the rifling depth to achieve the provisions of the rifling.

At present, the use of numerical control machine tools, so that the cutting tool while rotating forward cutting, so as to cut out the qualified rifling.

Rifling is the most important process in the whole body tube manufacturing, not only need high quality, high precision specialized machines and tools, but also require operators to have excellent skills.

New technology

With the development of technology, in addition to the traditional mechanical processing methods, foreign countries have emerged some more advanced processing technology.

In 2011–2012, the U.S. Army continued to develop new barrel processing technologies.

These included ceramic liners and refractory metal rifling, intended as alternatives to traditional chrome-plated liners. In addition, electrochemical processing technologies for regenerating artillery barrels were also explored.

The U.S. Army in recent years proposed and practiced the above three new technologies, its comparative advantages and innovations are.

(1) ceramic liner tube and refractory metal rifling processing technology

Explore a new rifling processing method different from the conventional mechanical broaching or electrochemical methods, so that refractory metal and ceramic liner tube more economically applicable to the body tube bore.

The U.S. Army has applied this process to 25 mm small-caliber and 120 mm and 155 mm large-caliber barrel lining rifling.

(2) Replacement of chrome plating tube lining technology for gun barrels.

The U.S. Army, in an effort to eliminate hexavalent chromium-containing chrome plating on gun barrels, has verified the feasibility of using Ta-10W liners for the 25 mm M242 “King of the Jungle” medium-caliber gun.

Tests at the Yuma Proving Ground have demonstrated at least a threefold increase in corrosion resistance compared with chrome plating of gun tubes.

(3) New economic and environmentally friendly regenerative electrochemical processing techniques have been developed.

New technologies have been developed for the direct recycling and regeneration of metal materials used in electrochemical processing.

These include methods for recycling alloys such as chrome–nickel–iron and chrome–copper, which are commonly applied in the electrochemical processing of artillery barrels of various calibers.

Problems such as electrochemistry of bore holes, rifling, cooling channels, gas flow channels and breech components for 40 mm calibre and large-calibre guns have been solved.

The adoption of the above new process has significantly improved the technological level and greatly reduced the machining cost.

Conclusion

The body tube is the most inconspicuous part of the artillery, but it is the most unique in the processing.

Although the machining of other structural parts of the artillery also has its own unique features, but compared with the body tube, it is slightly mediocre.

The quality of body tube machining is closely related to the life, firing accuracy and reliability of the whole artillery system, so the dimensional tolerance, roughness, curvature and other aspects of machining are extremely demanding.

Undoubtedly, the body tube processing is a distinctive feature of the artillery manufacturing technology which is different from that of ordinary machinery.

In order to meet the technical and tactical requirements of artillery and give full play to the combat effectiveness of artillery, it is necessary to attach great importance to the development of new materials for the body tube and the improvement of the processing technology.