China CNC Milling » Blog » Innovative Design of Side Core Pulling Mechanism for Injection Molds

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

During injection molding, when the side walls of the plastic part feature holes, grooves, or protrusions (i.e., undercuts), it is necessary to ensure that the side-molded components are extracted before demolding.

Therefore, the components formed at these locations on the mold must be designed with a side-movable structure and achieve demolding through the action of the side parting line and core-pulling mechanism.

Lateral parting and core-pulling mechanisms can be classified into three types based on their power source: manual, motorized, pneumatic, or hydraulic.

Among these, manual core-pulling mechanisms are generally only used in special situations such as new product prototyping or small-batch production due to their low production efficiency, high labor intensity, and limited pulling force.

Hydraulic or pneumatic core-pulling mechanisms, due to factors such as higher equipment costs, are generally primarily used in applications requiring high pulling force and long core-pulling distances.

Motorized core-pulling mechanisms, however, are the most widely used in production due to their advantages of ease of operation, high production efficiency, and suitability for automation.

Traditional motorized core-pulling mechanisms and their drawbacks

Motorized core-pulling mechanisms primarily include various forms such as inclined guide pillar parting core-pulling, inclined sliding block parting core-pulling, gear rack parting core-pulling, inclined piston core-pulling, and spring parting core-pulling.

Traditional motorized core-pulling mechanisms use the mold-opening force of the injection molding machine as their power source.

They rely on corresponding transmission mechanisms to change the direction of movement.

These mechanisms achieve lateral parting core-pulling and reset the lateral forming components through this redirected motion.

Therefore, in mechanical core-pulling methods, it is necessary to design a transmission mechanism capable of achieving core-pulling motion.

- Challenges of Common Core-Pulling Mechanisms

However, regardless of whether the core-pulling form is a inclined guide pillar mechanism, inclined pin mechanism, or inclined slider mechanism, issues such as complex core-pulling mechanism structure and potential motion interference between parts may arise.

Currently, the commonly used lateral core-pulling mechanisms primarily include the slider core-pulling mechanism and the inclined pin core-pulling mechanism.

If the inclined pin core-pulling mechanism is adopted, it may interfere with components such as support columns, ejector pins, ejector plates, and mold cores, and may also have a certain impact on the design of the water channels;

When using a slider core-pulling mechanism, there are fewer components in the mold that interfere with it compared to the inclined pin core-pulling mechanism.

Therefore, when both the inclined pin core-pulling mechanism and the slider core-pulling mechanism are feasible, the slider core-pulling mechanism is generally preferred.

However, the slider core-pulling mechanism has a complex structure, occupies a large amount of mold installation space, and has a higher mold manufacturing cost.

Therefore, this paper designs a rotary shaft side core-pulling mechanism tailored for situations where the undercut features on the plastic part are relatively shallow.

This rotary shaft side core-pulling mechanism features a simple structure, smooth motion, and easy installation, significantly simplifying the mold structure and reducing mold processing and assembly workloads.

Design of the Rotary Shaft Side Core-Pulling Mechanism

-

Core-Pulling Mechanism Structural Design

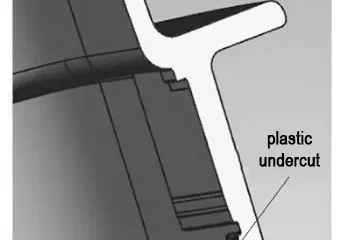

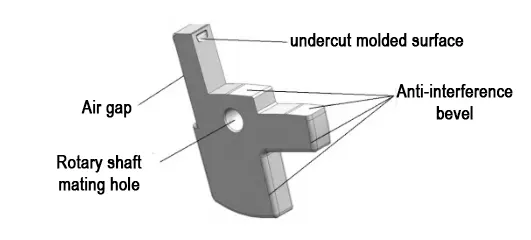

Figure 1 shows a schematic diagram of the undercut structure of a certain injection-molded part, which has an undercut feature on its inner wall.

The undercut measures 12 mm × 8 mm × 5 mm, with a depth of 5 mm. Both ends of the undercut feature chamfered corners to prevent the core-pulling mechanism from damaging the plastic part during rotation and demolding.

When using this type of core-pulling mechanism, it’s best to chamfer the ends of the undercut to reduce the risk of interference or part damage.

Figure 1: Schematic diagram of the undercut structure of the injection-molded part

> Design of the Undercut Insert

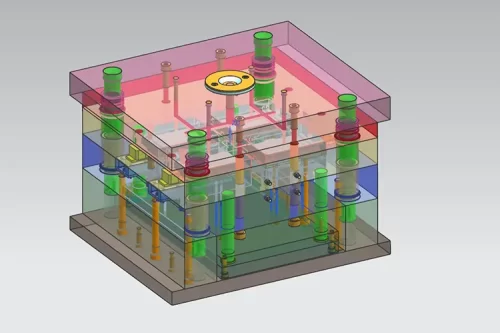

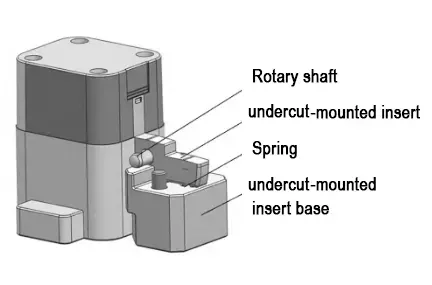

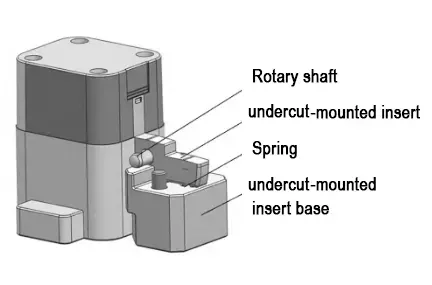

Based on the demolding requirements of the undercut feature of the plastic part, the designed undercut insert structure capable of rotational demolding is shown in Figure 2, and the fixation and assembly results of the insert in the mold are shown in Figure 3.

> Structural Features of the Undercut Insert

The mold cavity corresponding to the undercut feature on the molded plastic part is set as a separate insert, i.e., the undercut insert.

The undercut insert adopts a Z-shaped structural form. The insert is fixed via a base, which is equipped with springs to provide the power source for the insert to rotate around the rotational axis after mold opening.

The right side surface of the top of the undercut insert is designed with a molding surface for the undercut feature of the molded part; the middle of the insert is designed with an assembly hole feature that mates with the rotational axis.

Additionally, the undercut insert includes anti-interference surface features at the mating points with the mold cavity. These features prevent the insert from damaging the mold cavity during mold closing.

At the same time, a clearance groove is designed on the left side of the insert’s top surface. This groove ensures the insert has enough rotational space during undercut ejection.

-

Working principle of the core-pulling mechanism

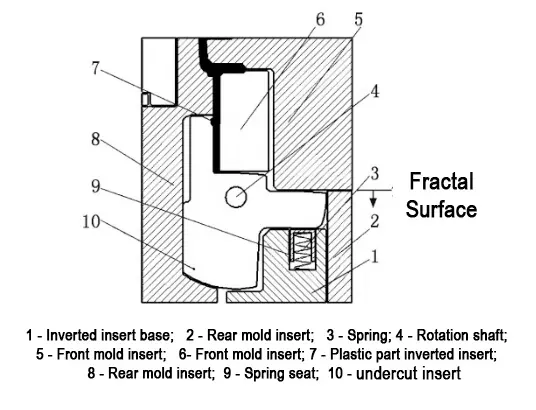

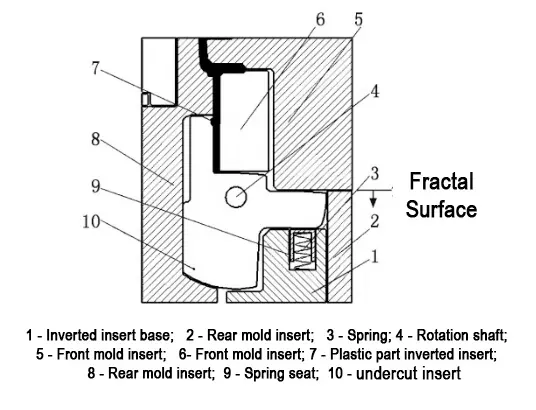

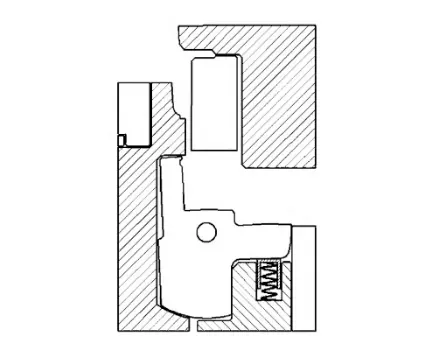

Fig 4 shows the working state of the undercut insert in the closed mold condition.

> Mold Closing Process and Energy Storage Mechanism

After the mold closes, the front mold cavity presses against the top surface of the undercut insert, causing it to rotate clockwise around the rotation axis.

The spring compresses and stores energy. When the lower left side of the undercut insert fully contacts the right side of the rear mold cavity insert (i.e., the limiting surface), the mold closing limit is achieved, and the mold closing injection molding process begins.

Figure 5 shows the working state of the undercut insert in the mold opening state.

> Mold Opening and Undercut Release Process

After the mold opens, the front and rear mold halves separate at the parting line. At the instant the parting line opens, the undercut insert rotates counterclockwise around the rotation axis under the force of the spring.

When it reaches a certain angle, the lower right side of the undercut insert fully contacts the left side of the insert base (i.e., the base limiting surface), achieving mold opening limiting.

The undercut feature of the plastic part is released from the undercut insert, thereby enabling normal mold opening and smooth demolding of the plastic part.

This type of rotary shaft-type side core-pulling mechanism solves the drawbacks of the sliding block core-pulling mechanism. The sliding block mechanism often has a complex structure and requires a large mold installation space.

It also overcomes the issues associated with the inclined pin core-pulling mechanism. The inclined pin mechanism can cause mold component interference and complicate assembly.

Additionally, it significantly simplifies the mold structure and reduces mold manufacturing costs.

This rotary shaft-type side core-pulling mechanism also offers the advantage of easy disassembly and assembly, significantly reducing the workload of toolmakers and improving production efficiency.

Conclusions

(1) The rotary shaft-type side core-pulling mechanism is suitable for rotating demolding core-pulling mechanisms in cases where the undercut feature is shallow (generally with an undercut depth not exceeding 10 mm).

(2) The angles at the contact surfaces between the undercut insert and the shaft base limiting surface, as well as the rear mold insert limiting surface, must be reasonably designed to ensure no interference occurs during the rotation of the undercut insert.

(3) The undercut insert must be equipped with reasonable anti-interference surfaces and clearance slots to prevent damage to the mold insert during the undercut insert’s return to its original position.