China CNC Milling » Blog » Injection-Molded Connector Warpage Control: Material and Process Optimization

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

As a critical component of electronic devices and systems, connectors have seen technological advancements in recent years aligned with industry trends.

Miniaturization represents one key development direction for connectors, addressing space constraints.

However, this trend also brings challenges in material selection. Miniature connectors typically feature thin walls and elongated structures.

Improper material selection or non-optimal injection molding parameters can lead to significant warpage during molding.

Uneven cooling rates across different sections of the part and nonuniform material shrinkage primarily cause this deformation.

For connectors subjected to high-temperature soldering processes, residual stresses from injection molding and material anisotropy can induce secondary warping deformation.

This phenomenon remains a persistent challenge for connector manufacturers.

This paper investigates how we can reduce warpage deformation in injection-molded industrial connectors by selecting appropriate materials and optimizing process parameters, particularly when mold optimization is limited.

Warpage Analysis

Connector Structural Analysis

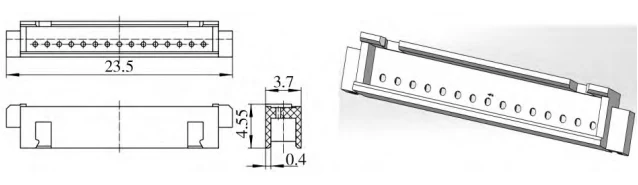

Figure 1 shows the two-dimensional drawing and three-dimensional model of the injection-molded part.

This part has a total length of 23.5 mm, a width of 3.7 mm, and a wall thickness of 0.4 mm.

Classified as a slender thin-walled structure, it is prone to warpage during both the injection molding process and high-temperature soldering operations.

Moldflow Simulation Analysis

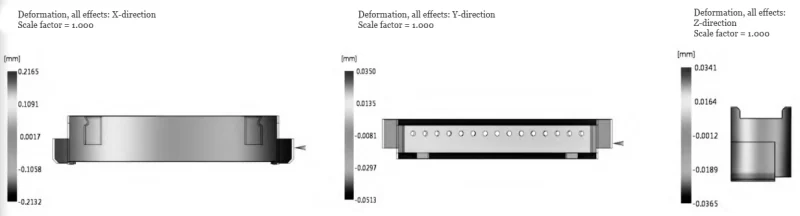

Prior to mold opening, the injection mold for this part underwent simulation analysis through optimized parameter settings.

Analysis results revealed the warpage deformation of the injection-molded part, as shown in Figure 2.

The figure indicates uniform shrinkage without warpage.

The X-axis direction (lengthwise) exhibits the greatest shrinkage at 0.

During dimensional design, we applied shrinkage compensation to ensure that the part’s dimensions met the specified tolerances.

Analysis of High-Temperature Welding Process

For designs deemed optimal through theoretical mold flow analysis, deviations from theoretical requirements inevitably occur during actual mold production and injection molding processes.

This leads to a series of issues in the practical application of injection-molded parts or connectors.

Multiple factors contribute to warping and deformation in injection-molded parts.

The following analysis examines these factors from the perspectives of material properties and injection molding process parameters:

1. Material Testing and Validation Analysis for Injection-Molded Parts

(1) Material Selection for Connector Injection-Molded Parts

Common materials for connector injection-molded parts include nylon, PPS, LCP, PBT, etc.

However, even within the same material type, varying performance metrics can lead to different degrees of warpage deformation.

Considering the structure of the injection-molded part in Figure 1, the connector must withstand reflow soldering as per customer requirements, demanding high temperature resistance.

Additionally, the thin walls necessitate dimensional stability, while the small pitch requires materials with excellent electrical insulation properties.

Analysis of material characteristics reveals: Nylon exhibits high moisture absorption and poor dimensional stability.

LCP, while offering high-temperature resistance and good flowability, tends to develop blistering after the high-temperature reflow soldering process, exhibiting unstable performance and higher cost.

PBT lacks sufficient heat resistance and exhibits significant post-molding shrinkage, making it unsuitable for this connector’s injection-molded part.

Therefore, we selected modified PPS material as the optimal choice for this connector’s injection-molded part.

(2)Properties and Testing of PPS

Polyphenylene sulfide (PPS) exhibits high rigidity and brittleness, high crystallinity, excellent flame resistance, strong mechanical performance, and excellent electrical properties.

Its heat deflection temperature typically exceeds 260°C, making it one of the highest-temperature-rated thermoplastic engineering plastics currently in use.

Its long-term service temperature ranges from 220°C to 240°C.

When used in connectors, glass fiber reinforcement is commonly added to enhance the strength and ductility of PPS.

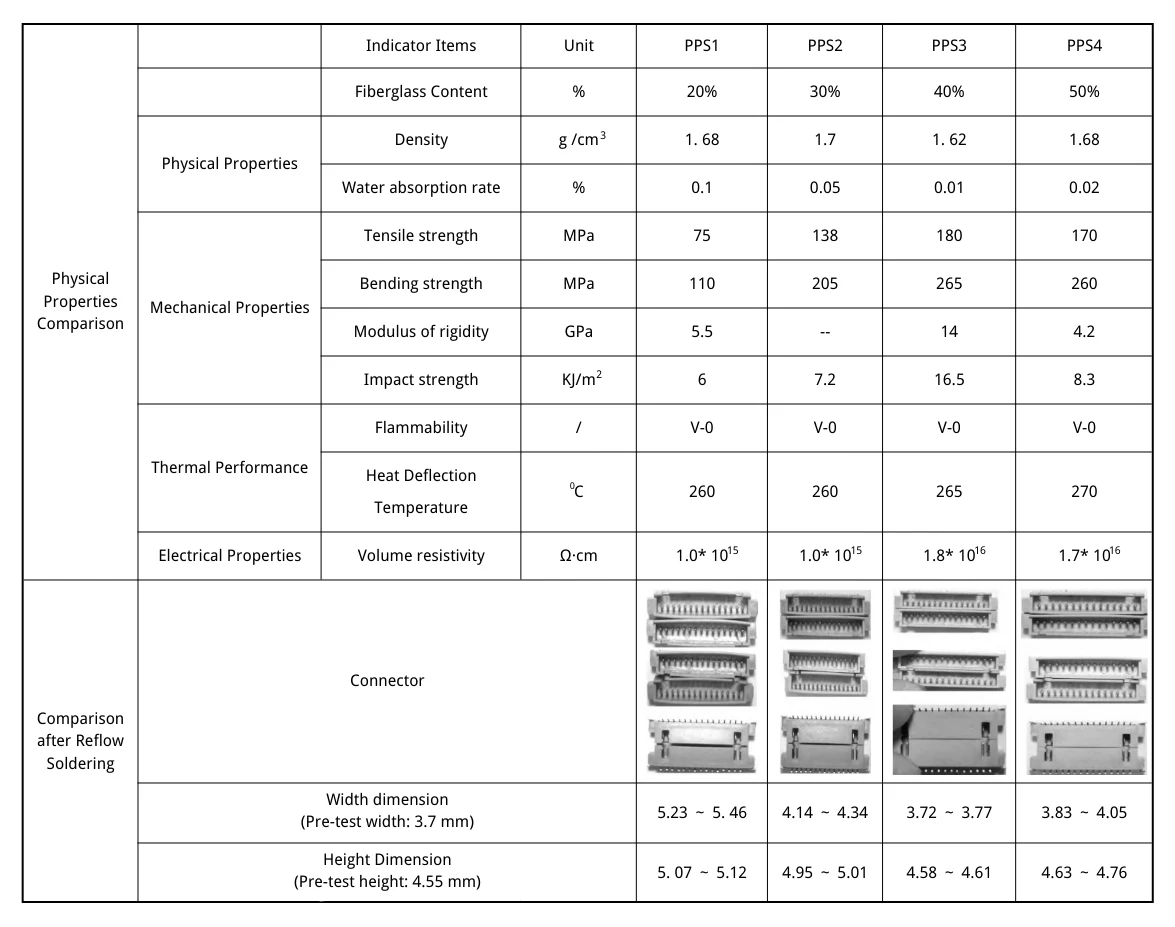

To evaluate this effect, we conducted the following test: four PPS samples with different glass fiber contents were injection-molded under identical process parameters and then subjected to reflow soldering.

The raw material properties and test results are presented in Table 1 to assess warpage deformation of the connector after reflow soldering.

The test results indicate that the warpage deformation of the connectors follows the order: 20% glass fiber content > 30% > 50% > 40%.

Different glass fiber contents within the same material exhibit distinct PPS performance metrics.

After reflow soldering, the test results also showed significant variations.

Comparing the PPS indicators in the physical properties table reveals that the heat deflection temperatures were largely similar.

Polyphenylene sulfide (PPS) combines high rigidity and brittleness, high crystallinity, excellent flame resistance, robust mechanical strength, and superior electrical properties.

The 20% glass fiber content injection-molded part exhibited the most severe warpage after reflow soldering, with tensile strength and flexural strength significantly lower than the other three PPS variants.

As glass fiber content increases, mechanical properties (tensile strength, flexural strength, impact strength) and electrical properties (volume resistivity) also improve. simultaneously reducing warpage deformation.

The 40% glass fiber content variant, exhibiting the lowest warpage deformation, demonstrated the highest impact strength, significantly exceeding that of the other three PPS variants with different glass fiber contents.

(3) Analysis of Warpage Deformation and Glass Fiber Content

Analysis of warpage deformation and physical property indicators reveals that adjusting the glass fiber content can modify the material’s performance metrics.

As glass fiber content increases, the resistance to shrinkage in the melt rises, thereby reducing warpage deformation in injection-molded parts.

Further research is needed to determine why warpage deformation reappears when the glass fiber content exceeds a certain threshold.

2. Experimental Validation Analysis of Injection Molding Process Parameters

Injection molding is a widely used process for manufacturing complex plastic parts, and shrinkage deformation critically influences their final dimensional accuracy.

The part in Figure 1 is relatively small with a high aspect ratio (slender) and features a thin-walled wall structure with a wall thickness of only 0.4 mm.

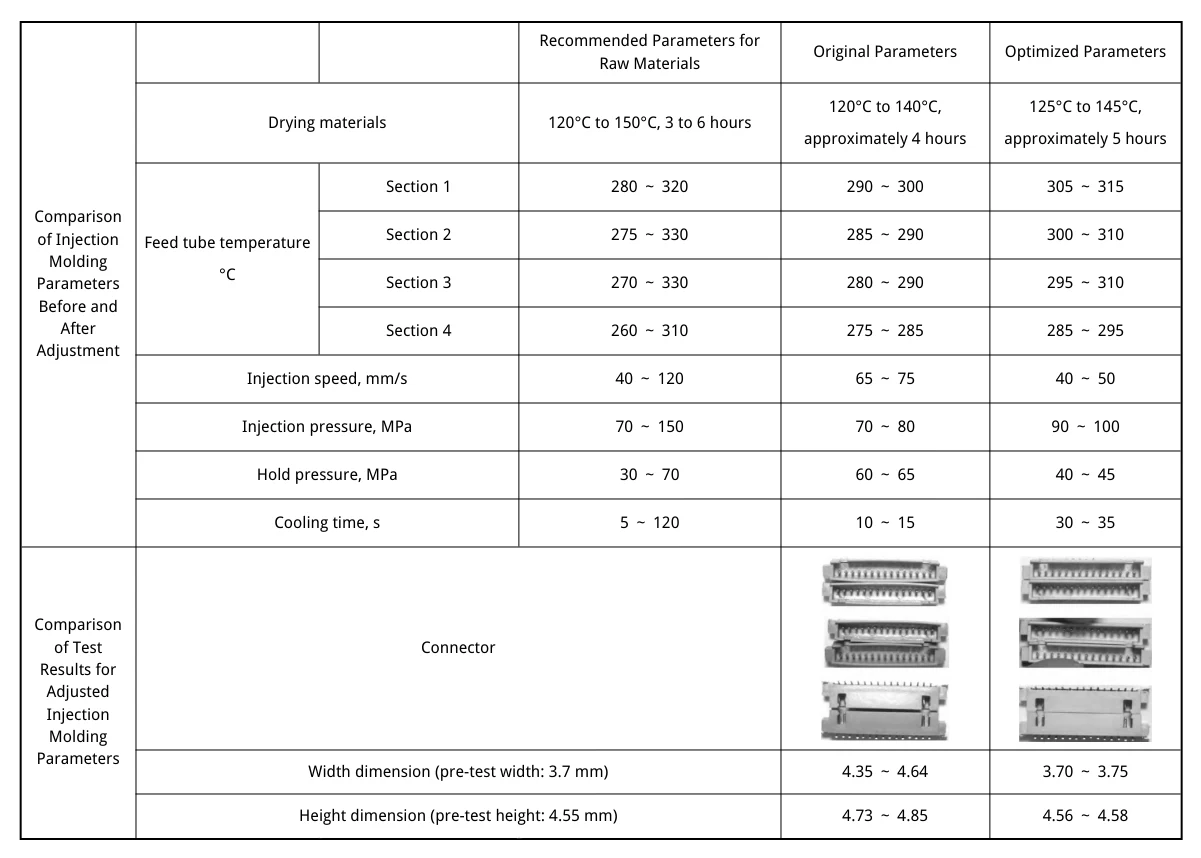

Drawing on our injection molding experience and consultations with suppliers, we select process parameters based on the part’s structural characteristics.

For wall-type components, different wall thicknesses require distinct injection parameters.

During molding, we must consider the following critical factors for small, elongated, thin-walled parts:

a) Material Drying: To achieve optimal part quality, PPS must undergo thorough drying prior to processing.

b)Barrel Temperature: We generally use lower barrel temperatures for larger parts and higher temperatures for smaller parts.

c) Injection Speed:Higher speeds increase the risk of warping. For small, thin-walled parts, we should reduce the injection speed.

d) Injection Pressure: High injection pressure is preferable for PPS to ensure part density and mechanical properties, especially for complex or thin-walled parts. Increasing injection pressure has minimal negative impact on molding.

e) Holding Pressure: Holding pressure should be kept as low as possible to prevent internal stress while ensuring sufficient shrinkage compensation.

f) Cooling time:Because PPS is a crystalline resin, we should appropriately extend the cooling time to achieve optimal mechanical properties.

Considering the part’s small size, high aspect ratio, and thin-walled structure, we validated PPS materials with identical glass fiber content by optimizing the injection molding parameters.

Table 2 shows the results of reflow soldering tests conducted after injection molding and before and after adjusting the injection process parameters.

Based on the images and data in Table 2, we produced the connector’s injection-molded parts using optimized parameters, effectively controlling warpage deformation after reflow soldering.

Improper selection of injection molding process parameters can also cause severe warpage deformation in the connector post-reflow soldering.

By adjusting the injection molding parameters, we resolved the warpage deformation issue.

We then conducted relevant inspections on the connectors after testing, and all results met the specifications.

Summary

Through relevant verification and analysis, we adjusted the raw material composition of the injection-molded parts to achieve an optimal glass fiber content and enhanced the performance metrics of the raw materials.

In addition, we investigated the optimal injection molding process parameters for controlling warpage, effectively mitigating deformation in connectors after reflow soldering.

This approach yields a solution that minimizes warpage deformation to the greatest extent possible.