China CNC Milling » Blog » Injection Mold Design for High-Quality Electric Mosquito Coil Heater Plastic Covers

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

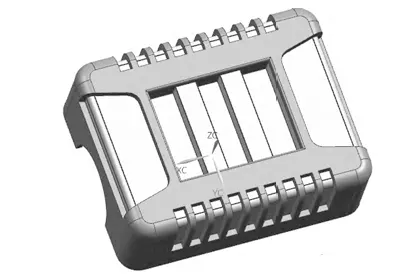

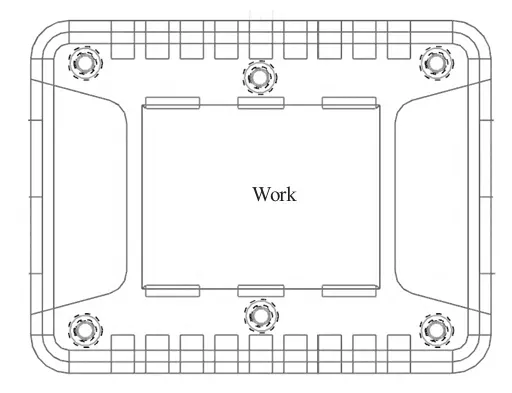

Electric mosquito coil heaters are common household items in people’s daily lives. Their plastic casing components must be aesthetically pleasing, durable, and safe.

The structure is shown in Figure 1.

Technical Requirements:

(1) The surface of the heater cover shall be smooth, free of noticeable protrusions or pits, without bubbles or cracks, and exhibit uniform coloration.

(2) The heater cover must withstand elevated temperatures to prevent deformation or damage under high heat conditions.

(3) The plastic material of the heater cover shall be non-toxic and harmless, possess good flame-retardant properties, and resist discoloration or dissolution at high temperatures.

Process Analysis of Plastic Parts

Process Analysis of Plastic Parts

The plastic component for the upper cover of the electric mosquito coil heater is made of PP.

Its characteristics include being colorless, odorless, and non-toxic.

It is heat-resistant and has good tensile and flexural strength.

The material also exhibits flame-retardant properties.

It offers excellent chemical stability and good thermal stability at high temperatures.

In addition, it provides superior electrical insulation, low moisture absorption, and resistance to humidity.

It is widely used in the injection molding industry.

Forming Properties of PP Material:

(1) Excellent flowability; avoid excessive injection pressure. Flash tolerance: 0.03 mm.

During injection molding, carefully control melt temperature and pressure to ensure uniform filling of the mold cavity, resulting in good dimensional stability after molding.

(2) High shrinkage rate, typically 1%–5%, prone to warping and deformation.

Avoid sharp corners in plastic parts. During injection molding, consider using appropriate mold structures and process parameters to minimize shrinkage.

(3) Mold temperature significantly affects shrinkage rate, with prolonged cooling time required.

Selection of Injection Molding Machines

Before designing injection molds, it is essential to understand the technical specifications and operational performance of the selected injection molding machine.

This ensures that the mold and the machine coordinate properly, allowing operators to correctly install and use the designed mold on the injection molding machine.

Based on the UG 3D model of the heater cover, the volume of the heater cover was obtained using the “Measure Volume” command in the “Analysis” module: V1 = 5.52 cm³.

The plastic part features regular geometry with dimensions and tolerances of moderate complexity.

We propose a two-cavity mold configuration, using a balanced, left-right symmetrical cavity layout to facilitate even material flow and distribute mold forces evenly.

The estimated volume of the gating system is: V2 = 6.63 cm³. The total plastic volume is calculated as: V = 2 × V1 + V2 = 17.67 cm³.

Considering the company’s existing molding equipment, the injection molding machine model selected is XS-Z-30.

Optimized Mold Design

Based on the structural characteristics and technical requirements of the electric mosquito coil heater’s top cover, we designed a three-dimensional plastic part model.

We used UG software as the design platform.

We applied Mold Wizard for computer-aided analysis and mold design, following the specific process outlined below.

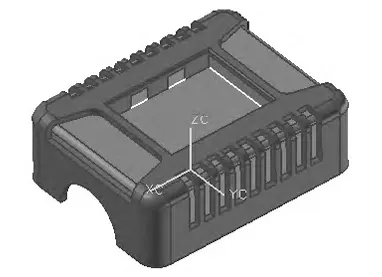

Optimized Design of Core and Cavity

The core and cavity directly contact the plastic part, serving as components that determine its shape and dimensions.

To ensure the precision of the plastic part, the core and cavity must possess sufficient dimensional accuracy and surface roughness.

Therefore, the structural design of the core and cavity is crucial—the simpler the structure, the easier it is to guarantee machining precision.

The upper cover of the electric mosquito coil heater features numerous heat dissipation holes and a complex shape.

Before parting, these open areas require patching operations.

The form of the patches directly determines the structure of the core and cavity, significantly impacting subsequent CAM programming and machining.

The patch shown in Figure 2 employs the [Surface Patch] and [Extrude] commands.

The uneven surface of the central patch results in complex core and cavity geometries, making it difficult to remove flash from the machined plastic part.

Figure 3 employs commands such as [Bridge] and [Surface] to design both the central and side patches as flat surfaces.

This addresses the shortcomings of the patch in Figure 2, resulting in improved core and cavity formation within the mold and facilitating easier subsequent flash removal.

Based on the structural shapes of the components shown in Figures 2 and 3, the split patch depicted in Figure 3, though more complex to operate, facilitates subsequent CNC machining programming.

Moreover, plastic parts produced by injection molding exhibit easier flash removal.

Therefore, we prefer the split patch shown in Figure 3.

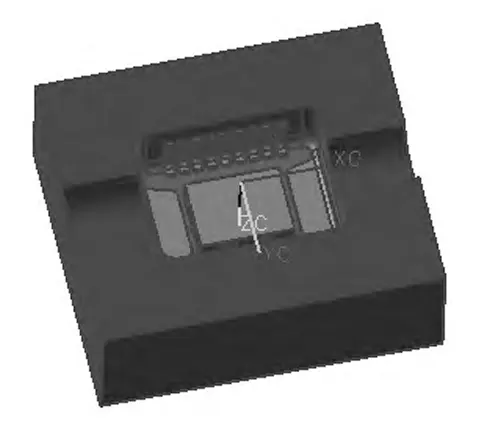

After editing the parting surface and curved surface patches, we created the regions and designed the parting.

Figures 4 and 5 illustrate the resulting cavity and core.

Design of the Gate System

The gate system serves as the flow channel for molten plastic from the injection machine nozzle to the mold cavity.

It directly affects molding efficiency as well as the appearance, structure, and internal quality of plastic parts.

A standard gate system typically comprises a main runner, runner system, gate, and cold runner cavity.

We generally design the main runner as a bushing-type runner to facilitate the use of standard components and improve mold design efficiency.

Given this mold’s balanced two-cavity layout and the relatively compact size of the plastic part, we selected a trapezoidal cross-section runner for easier machining.

The gate, being the narrowest cross-sectional element in the system, is its critical component.

Its position, shape, and dimensions directly influence part quality and production efficiency.

Based on the structural characteristics of the electric mosquito coil heater’s top cover, this mold employs a rectangular gate with side feeding.

Its advantages include uniform material feeding, easy control of filling parameters, and good plastic flow.

It is particularly suitable for thin-walled and complex cavities, making it one of the most commonly used gate types in multi-cavity molds.

The rectangular cross-section design is simple and easy to machine, facilitating precise gate finishing to achieve low surface roughness.

Rectangular gates are easy to trim manually, leaving minimal residual marks, ensuring high part accuracy, and reducing subsequent trimming work.

The cold runner cavity collects cooler melt near the nozzle tip, preventing defective material from entering the cavity.

Typically positioned on the moving platen opposite the main runner, it is secured to the ejector pin mounting plate of the ejection mechanism.

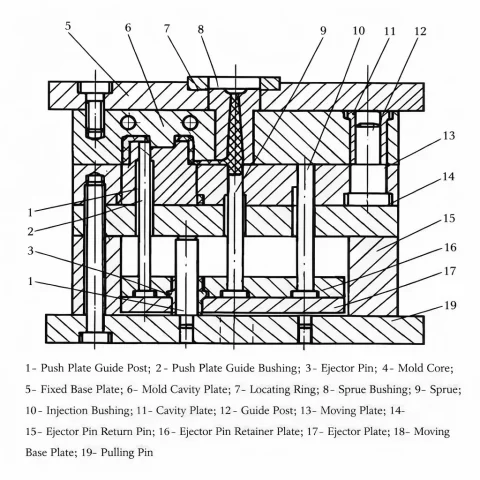

This mold employs a standard hook-shaped ejector pin, with its specific shape and location shown as part 9 in Figure 7 (Mold Assembly).

Design of Ejection Mechanisms

After the plastic parts cool during molding, operators must remove them from the mold to proceed to the next production cycle.

Therefore, designing an ejection mechanism is essential.

The rationality of the ejection mechanism directly impacts the dimensional accuracy and surface finish of the plastic parts.

We can classify common ejector mechanisms into several types based on the category of ejected parts.

These include push-rod ejectors, push-tube ejectors, ejector plate mechanisms, ejector block mechanisms, and combined ejector mechanisms.

Considering that the upper cover of the electric mosquito coil heater lacks tubular structures and is not a flat plastic part, a push-rod ejector mechanism is the preferred choice.

Push rods are standard components, making the push rod ejector mechanism simple in structure, easy to assemble, and convenient for maintenance and replacement.

The fit precision between the push rod and the mold plate/core is easily controlled, ensuring flexible and reliable ejection.

The electric mosquito coil heater’s upper cover features a rectangular prism shell structure with overall symmetry and uniform shell thickness.

Arranging six 2 mm diameter push rods evenly along the inner edge fully satisfies the ejection requirements.

The position of the push rods on the plastic part is shown in Figure 6 (circular section).

Mold Assembly Drawing

Based on the above analysis, we created a 3D mold assembly drawing using the UG Mold Wizard module and converted it into a 2D engineering drawing, as shown in Figure 7.

The operational sequence is as follows: During mold closing, the injection machine’s mold opening/closing system drives the moving mold plate toward the fixed mold plate.

Guided by the guide bushings 11 and guide pins 12, the moving and fixed mold plates align at the parting line.

The core 4 and fixed mold plate 6 form two closed cavities matching the shape and dimensions of the plastic part.

After the injection molding machine’s clamping system secures the mold, molten plastic is ejected from the machine’s nozzle.

It flows through the sprue bushing 8, the runner, and the gate into the cavities.

The injection process includes filling, holding pressure, and backflow until the gate cools and solidifies.

Holding pressure is no longer required at this point. The injection machine’s screw retracts.

Meanwhile, the mold and plastic part continue to cool. When the plastic part cools to a certain temperature, demolding can proceed.

The moving mold section moves under the action of the injection machine’s mold opening mechanism.

The mold first separates between the fixed plate 6 and the moving plate 13.

Due to the clamping force exerted by the cooling plastic part on the core, the plastic part and the sprue system scrap remain on the moving mold side.

Under the action of ejector pin 9, they move together with the moving mold section.

After traveling a certain distance, the injection machine’s ejection mechanism activates.

Driven by the ejector pins, the ejector mechanism pushes the plastic part out, completing one injection molding cycle.

Conclusion

Through process analysis of the plastic upper cover for electric mosquito coil heaters, mold structure design was conducted.

To enhance the surface quality of the plastic part and reduce the difficulty of core and cavity machining, the surface patching method for the plastic part was analyzed in detail.

A combination of surface modeling and plastic molding tools was employed to optimize the design of the core and cavity components for the injection mold.

The gating system and ejection mechanism were selected for their simple machining, reliable operation, and low-cost structure.

Production practice demonstrates that this mold structure design is rational.

It achieves high surface machining precision for the cavity and ensures superior surface quality of the plastic part.

Production practice demonstrates that this mold structure design is rational.

It also achieves high surface machining precision for the cavity and ensures superior surface quality of the plastic part.