China CNC Milling » Blog » How Cutting Equipment Processes Inspire Smarter Sheet Metal Design?

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Upgrading sheet metal processes by updating equipment is a common approach adopted by many enterprises today.

However, within just a few short years, sheet metal equipment has entered a stagnation phase. It is boldly predicted that over the next several years or even decades, sheet metal equipment may not undergo significant changes.

Concurrently, many companies have seen little advancement in their sheet metal design and process capabilities.

The root cause lies in the inherent potential for structural innovation within equipment process characteristics—a genetic code that remains underutilized and deeply unexplored.

This creates the perception of using high-end equipment to produce low-end products, resulting in minimal added value.

Therefore, it is essential to fully leverage the latent process features of high-end equipment to achieve premium sheet metal manufacturing, thereby elevating product design standards.

Beyond the now obsolete shearing machines, the current market is dominated by CNC punching presses, laser cutters, or integrated systems combining both.

In-depth exploration of the inherent process capabilities within CNC punching presses and laser cutters can yield unexpected design outcomes for sheet metal components.

Process Capabilities of CNC Punching Presses

Beyond performing the unfolding and blanking of three-dimensional sheet metal parts, what other inherent process functions of CNC punching presses influence structural design?

The following case studies illustrate the interactive relationship between process and design, and how these characteristics can be leveraged for optimization.

Forming Functions for Structures Like Louvers

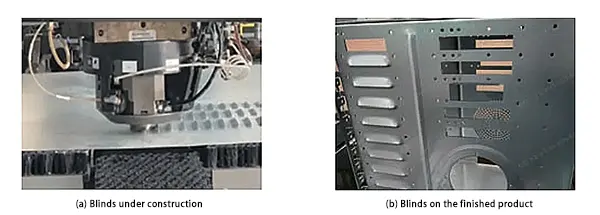

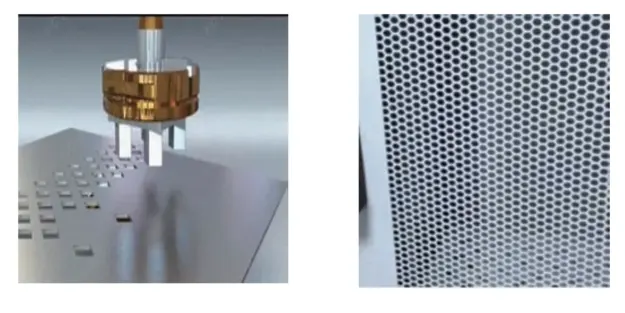

Louvers are widely used in sheet metal industrial design for ventilation, heat dissipation, aesthetic appeal, and structural reinforcement. Figure 1 shows louvers produced on a TRUMPF CNC punch press and their application on a finished product.

Of course, louvers represent only one aspect of CNC punching forming processes. Others include beading, step forming, embossing, stamping, flanging (punching holes), deep drawing, countersinking (chamfering), edge bending, edge rolling, and hinge rolling.

For sheet metal design, understanding the above functions is insufficient. One must also grasp the principles of CNC forming:

First, material suitability: Materials with good ductility are suitable for complex forming. Stainless steel or high-carbon steel should minimize deep drawing or sharp-angle forming.

Second, die compatibility: This includes die parameters, applicable scenarios and ranges, and die change sequences for multi-station forming.

Third, demand-driven R&D integration: Many forming processes on CNC press brakes result from collaborative exploration between end-users and die developers.

In summary, fully leveraging the process capabilities of CNC press brakes optimizes design solutions, achieving lightweight, high-strength sheet metal parts while simultaneously enhancing production efficiency.

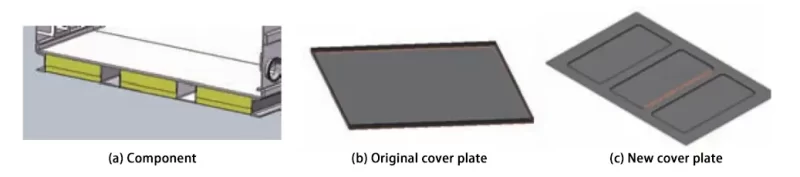

For instance, in the case of an insulation cover plate for the oil tank of a deep-frying appliance, the customer required full welding.

Considering thermal expansion and contraction, a new structure featuring a flanged plate with rolled ribs was ultimately selected, as shown in Figure 2.

Positioning Functionality of Semi-Shear Structures

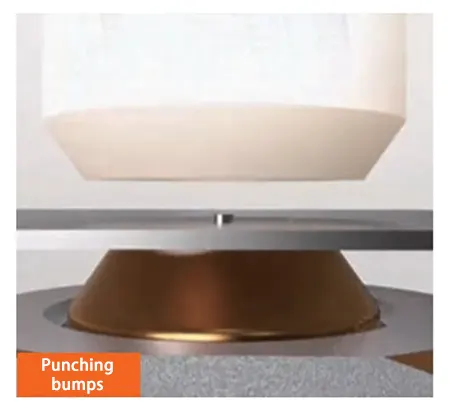

Semi-shear utilizes the punching principle of CNC press brakes to create incomplete separation of material, forming raised projections on the reverse side for positioning and connection with other components.

As shown in Figure 3, since the stamped material remains partially joined, the raised projections function in an “embedded” state during positioning, enabling greater shear force resistance after welding.

Additionally, employing “plug welding” prevents extensive weld penetration on the front surface, achieving optimal surface integrity without damage, as shown in Figure 4.

Positioning capability is an essential skill for advancing sheet metal design, manufacturing processes, and production standards.

It ensures that each component’s spatial position and dimensions are fixed during assembly, as illustrated in Figure 5.

Traditional sheet metal production often overlooks this, relying on manual marking or on-site fitting. Modern sheet metal structures emphasize the integration of design, process, and manufacturing.

By utilizing the auxiliary functions of advanced equipment to achieve positioning on parts, this ensures product quality, improves production efficiency, reduces costs, and lowers energy consumption—an innovation in itself.

The semi-shear process exemplifies how CNC punching presses achieve positioning functionality.

It facilitates subsequent sheet metal operations while improving product aesthetics, making it prevalent in high-end materials and manufacturing scenarios.

Additionally, CNC punching presses employ other positioning methods—such as hole-to-hole alignment, marking techniques, and mortise-and-tenon structures—which should be applied judiciously based on precision requirements.

Design of Matrix Hole Structures

Matrix holes serve not only functional purposes but also as design highlights, as illustrated in Figure 6.

On one hand, matrix holes represent a prominent CNC punching technique, offering ventilation, electromagnetic shielding, and heat dissipation capabilities.

On the other hand, they incorporate modern elements like contemporary aesthetics and technological sophistication, resulting in products that are minimalist yet refined, demonstrating a degree of trend-setting potential.

The limitations of matrix holes stem from constraints like mold costs, machine tool efficiency, and quality control, making them primarily suitable for specific products or high-volume production.

Key Process Considerations for Laser Cutting Machines

Laser cutting represents another common method for sheet metal blanking, particularly suited for high-end materials like stainless steel.

Similarly, laser cutting equipment possesses distinct process characteristics that not only facilitate post-production processing but also provide indispensable support for preliminary design and process planning.

Matrix Hole Design

Industrial design for laser-cut matrix holes offers significantly greater flexibility than CNC punching. Key advantages include faster cutting speeds, minimal deformation, and the ability to achieve novel industrial designs without mold costs for hole shapes and arrangements.

Weight Reduction and Structural Reinforcement Design

Food processing machinery typically demands high/low temperature resistance, corrosion resistance, long-term stability, and hygiene compliance—imposing stricter requirements on sheet metal fabrication.

A function-oriented thickness design philosophy is key: critical load-bearing components like drive shafts, support plates, and impact-resistant parts require reinforcement;

non-functional areas employ hollowed-out or thinned designs to reduce weight and lower costs.

For example, the tensioning structure column of a certain machine uses stainless steel material with a thickness of 5mm and a length of 2400mm. Calculations indicate a bending force requirement of 166 tons.

While press brakes like the AK 220-ton and TRUMPF 320-ton models exceed this capacity, no bending dies capable of supporting 97 tons per meter are available (standard dies typically handle 70–80 tons per meter), rendering processing impossible.

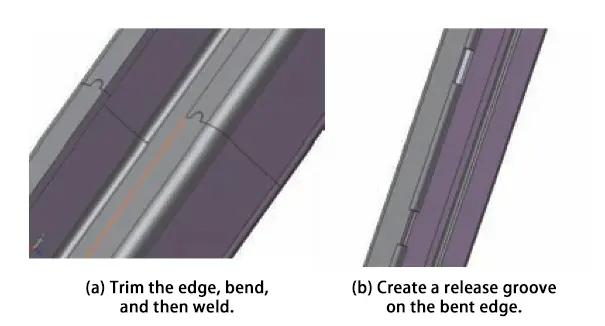

Through finite element analysis, laser cutting was identified as a viable manufacturing method for the part, with two primary approaches:

As shown in Figure 7, the first involves cutting apart the two bent edges while retaining the base plate, followed by welding after bending;

The second involves cutting release slots along the bend edge to reduce the effective bending length and pressure per unit length, enabling part fabrication.

This demonstrates that laser processing not only achieves structural weight reduction and reinforcement but also facilitates part production while lowering costs—truly killing two birds with one stone.

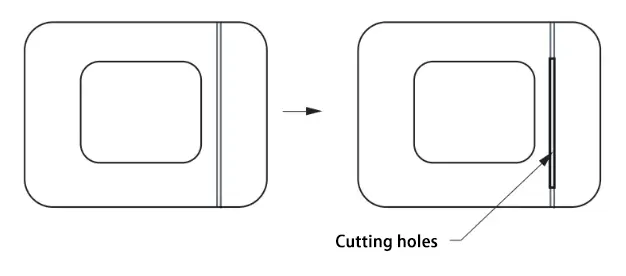

Post-Processing Implementation

Laser cutting technology ensures the feasibility of subsequent sheet metal processes. For instance, it offers the most rational solution for addressing holes near bend edges, as illustrated in Figure 8.

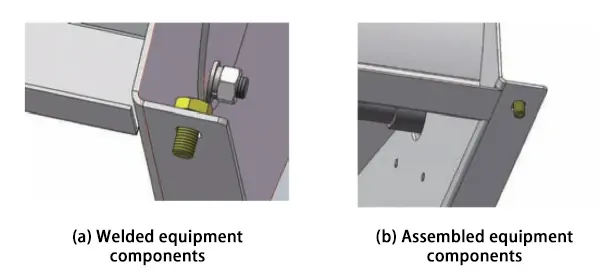

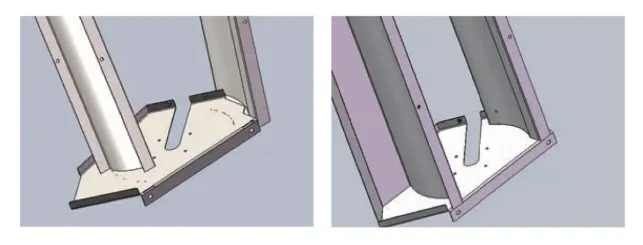

Consider a device assembly composed of sheet metal components. If welded, it would require substantial filler wire, leading to significant deformation and an unattractive appearance.

By employing laser cutting, the welding process is transformed into an assembly process, effortlessly resolving this challenge, as shown in Figure 9.

Positioning and Interlocking Techniques for Sheet Metal Assemblies

Sheet metal assembly design transcends simple part stacking. Each component exists in three-dimensional space, necessitating solutions for positioning to ensure precise geometric relationships.

First, positioning ensures assembly accuracy and relative dimensional precision during part fabrication;

Second, it facilitates quality control by minimizing human error;

Third, positioning design streamlines processes, reduces manual adjustment time, and boosts production efficiency—particularly for single-piece or small-batch production;

Fourth, it minimizes welding distortion. Laser cutting enables positioning through workpiece contours, engraved lines, mortise-and-tenon joints, locating holes, or flanges—selecting appropriate methods for different scenarios.

Interlocking designs (such as clips or mortise-and-tenon joints) enhance the rigidity of parts and assemblies. They serve as a means to ensure precision, demonstrate the product’s manufacturing quality, and improve production efficiency by reducing unnecessary labor.

Through rational positioning and interlocking structures, sheet metal assemblies can achieve a balance between functionality, economy, and aesthetics. They also meet modern manufacturing demands for high efficiency, precision, and low cost.

The internal assembly of a refrigeration unit comprises two curved mounting plates and end side plates. During blanking, laser marking lines and interlocking techniques were employed.

The two curved plates and side plates were positioned and secured via manual TIG multi-spot welding to ensure precise geometric relationships between diagonals and planes before entering centralized machining.

Corner welds are performed using handheld laser welding with filler wire, while flat welds utilize manual TIG welding without filler wire. Post-welding, the assembly exhibits no deformation and maintains precise dimensions, as shown in Figure 10.

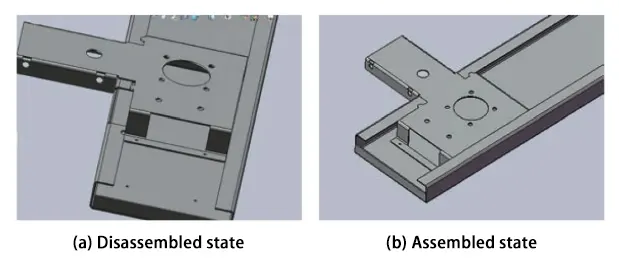

A base plate assembly for a refrigeration unit comprises sheet metal components. The design incorporates positioning features (two semi-circular thin plates, locating holes, etc.).

The interlocking sections employ a notched fit with minimal clearance, ensuring dimensional accuracy, precise geometric tolerances, and no deformation.

This serves as a prime example of process demonstration and exemplifies exceptional manufacturability, as shown in Figure 11.

Implicit Marking Functionality

Marking is also an indispensable element in sheet metal design. Many laser cutting machines come equipped with a “DMP” system that can apply QR codes, barcodes, and other identifiers during part blanking.

This aids in workpiece identification and enables product information traceability.

Most manufacturers apply simple markings to workpieces for differentiation, such as abbreviations of technical drawing numbers. This facilitates rapid workflow and enhances production efficiency.

Figure 12 illustrates a method of workpiece identification achieved through laser engraving during production.

Note that engraving should be performed on non-A-grade surfaces or hidden areas.

Figure 12 Laser Engraving Identification Commercial identification refers to markings containing specific information applied to products before shipment.

This aids enterprises in managing product information, expanding brand recognition, and enhancing influence.

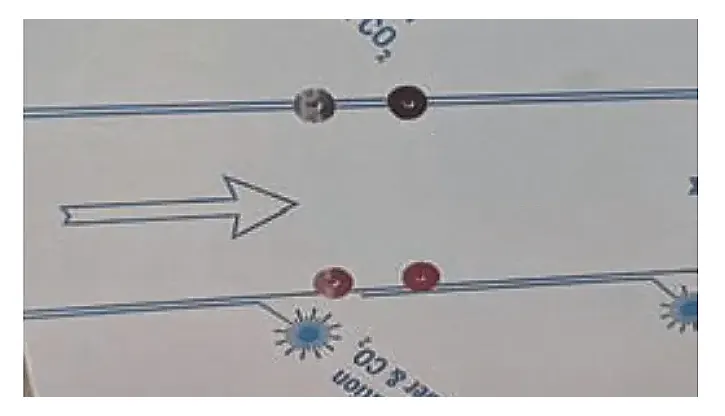

Figure 13 displays commercial markings on export products, also achieved using the latent marking capabilities of laser cutting equipment.

These markings exhibit high quality, rivaling UV printing, and fully showcase the company’s professional equipment and advanced manufacturing processes.

Relationship Between CNC Punch Presses and Laser Cutting Machines

Both CNC punching presses and laser cutting machines are excellent equipment for sheet metal blanking. With the development of stainless steel sheet metal, many believe laser cutting machines are more suitable than CNC punching presses.

In the food machinery industry, laser cutting machines hold a significant advantage when processing stainless steel plates with thicknesses of 4–6mm.

However, when processing thin plates less than 3mm thick, CNC punching presses and laser cutting machines are complementary, each offering distinct advantages.

Companies invest millions in purchasing equipment, yet before fully grasping its process capabilities, newer models emerge—trapping them in a vicious cycle.

Even after deploying numerous advanced machines, their design capabilities remain stagnant.

Compared to international sheet metal peers, what may be lacking is perseverance and resolve—the very essence of professionalism.

Boldly predicting the future, laser forming integrated machines may emerge as the dominant equipment for sheet metal blanking, potentially occupying the top spot among blanking devices for an extended period.

Conclusion

As sheet metal designers, we must first cultivate a closed-loop process mindset. From blanking precision at the ten-micron level to millimeter-level coordination in assembly clearances, every process in sheet metal fabrication should demonstrate the perfect synergy between design and manufacturing.

Only when process and design engage in a two-way dialogue can theoretical extremes be transformed into achievable precision on the shop floor, paving the way for solid strides toward high-end sheet metal manufacturing.

Sheet metal design is inherently part of industrial design.

Design thinking has transcended traditional two-dimensional constraints, evolving from simple design to systematic design—achieving symbiotic coexistence between artistry and functionality.