China CNC Milling » Blog » How to Improve Efficiency in High-End Mold Manufacturing and Precision Machining?

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

With the rapid development of global manufacturing, the demand for high-end molds and precision machining services continues to grow. Their processing efficiency directly impacts corporate competitiveness and market responsiveness.

Traditional machining methods struggle to meet the dual demands of precision and efficiency, making technological upgrades imperative.

Enhancing processing efficiency requires optimization in design and techniques.

It also requires the integration of intelligent and automated technologies, along with scientific equipment maintenance and process management.

Exploring specific methods to boost the machining efficiency of high-end molds and precision machinery helps shorten production cycles.

It also improves product quality and reduces costs, serving as a key driver for further manufacturing advancement.

Optimization of Product Design and Process Flow

The efficiency of high-end mold and precision machining relies heavily on the optimization of product design and process flow during the preliminary stages.

Rational design not only determines the machinability of components but also directly impacts subsequent manufacturing costs and timelines.

During the product design phase, full consideration should be given to part geometric complexity, material properties, and assembly requirements.

This ensures that the design structure aligns with actual production conditions.

Reducing overly complex structural designs can lower machining difficulty and prevent production bottlenecks or rework caused by design flaws.

To enhance machining efficiency, the design phase must closely integrate feasibility analysis of manufacturing processes.

Particularly in multi-process machining, rational part decomposition and assembly optimization reduce machining errors caused by repeated positioning and clamping.

Process flow design involves sequencing operations, selecting appropriate equipment, and optimizing process parameters.

Optimizing production line configurations minimizes unnecessary handling, clamping, and idle waiting times, thereby enhancing production continuity.

Advanced planning methods like Computer-Aided Process Planning (CAPP) systematically analyze optimal process paths to ensure seamless operation-to-operation transitions and eliminate redundant steps.

Furthermore, with the advancement of digital manufacturing technologies, the product design phase can leverage simulation techniques.

It can also use virtual manufacturing methods to preemptively validate design manufacturability.

This approach reduces costs associated with later debugging and trial-and-error adjustments.

By strengthening the optimization of both product design and process flow, machining efficiency can be enhanced.

Overall product quality and consistency can also be significantly improved, ultimately bolstering the company’s market competitiveness.

Enhancing Efficiency in High-End Mold and Precision Machining

-

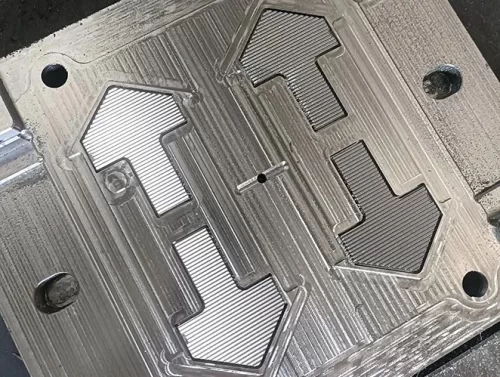

CNC Programming Optimization

Optimized programming not only reduces machining time but also improves workpiece surface quality and machining accuracy.

During programming, the rational selection of tool paths, feed rates, and cutting depths is crucial for improving machining efficiency.

For example, in aluminum alloy machining, appropriate cutting speeds typically range from 600 m/min to 1200 m/min, with feed rates of 0.2 mm/rev to 0.4 mm/rev.

Such parameter configurations ensure surface finish while minimizing excessive wear and heat accumulation.

When processing steel, cutting speeds are typically reduced to 100 m/min to 300 m/min, while feed rates are controlled between 0.1 mm/rev and 0.3 mm/rev to prevent excessive cutting forces and tool breakage.

During CNC programming, advanced CAM software can automatically generate optimal tool paths, eliminating unnecessary idle tool movement.

Reducing idle time significantly improves machine utilization. Studies indicate that optimized paths can cut idle time by 10% to 20%, directly enhancing machine efficiency.

Simultaneously, rationally setting tool entry/exit points and cutting sequences prevents overcutting and tool collisions, further reducing machining errors.

For complex multi-axis parts, programming optimization on five-axis CNC machines is particularly crucial.

Precise tool paths and motion control minimize the need for multiple setups, thereby reducing positioning errors in production and enhancing machining accuracy.

Furthermore, simulation in CNC programming serves as an effective method to preempt potential issues during actual machining.

By simulating the machining process in a virtual environment, path interference and tool collisions can be identified in advance, thereby reducing trial cutting and debugging time.

Research indicates that simulation technology can reduce production error rates by 30% to 50% while lowering tool wear and scrap rates.

In summary, optimizing CNC programming enhances machining efficiency.

It also improves production economics and flexibility by minimizing errors, optimizing tool paths, and enhancing surface quality.

-

Tool Selection and Design

Tool selection and design play a decisive role in high-end mold manufacturing and precision machining.

The rational selection of tool materials, shapes, coatings, and geometric parameters can significantly enhance cutting performance and extend tool life.

When machining high-hardness workpieces, such as mold steels exceeding HRC 50, coated carbide tools or cubic boron nitride (CBN) tools are typically selected.

These tools offer superior wear resistance and thermal stability, maintaining extended service life under high-temperature, high-speed cutting conditions.

Tool geometric parameters—including rake angle, clearance angle, and cutting edge length—directly influence cutting forces and chip evacuation performance.

For example, during rough machining, a larger front angle and shorter cutting edge length can reduce cutting forces.

This helps minimize tool wear, improve chip evacuation efficiency, and prevent built-up edge formation.

When machining different materials, tool parameters should be adjusted according to the material’s cutting characteristics.

For aluminum alloy machining, tools with large rake angles and sharp cutting edges are recommended to minimize temperature rise during cutting and improve surface finish.

For difficult-to-machine materials like stainless steel, tool coatings with high hardness and low friction coefficients should be selected.

Examples include titanium nitride (TiN) and titanium carbonitride (TiCN). These coatings help reduce tool wear and extend service life.

The selection of cutting speed and feed rate parameters is also critical.

For example, in aluminum alloy machining, the recommended cutting speed ranges from 600 m/min to 1200 m/min, with a feed rate of 0.2 mm/rev to 0.4 mm/rev.

When machining stainless steel, the cutting speed should be reduced to 100 m/min to 300 m/min, with a feed rate of 0.1 mm/rev to 0.3 mm/rev.

By appropriately selecting and designing cutting tools, machining efficiency can be effectively enhanced, tool replacement frequency reduced, and overall machining stability and precision improved.

-

Machine Tool Configuration and Layout Optimization

Efficient machine tool configuration minimizes downtime during machining, reduces errors caused by repeated setups, and enhances overall machining efficiency.

In multi-process machining, utilizing five-axis or multi-axis CNC machines enables simultaneous machining of multiple surfaces and complex curves with a single setup.

This significantly reduces errors caused by repeated setups and alignment, particularly when processing intricate parts.

Five-axis machines excel at minimizing positioning errors, ensuring machining accuracy maintained within ±0.01mm.

A rational machine layout minimizes non-value-added activities during processing, such as workpiece handling and waiting times.

Arranging machines for related processes according to the workflow reduces the distance workpieces travel within the machining area.

For example, when machining large molds, placing CNC milling machines, finishing machines, and grinders in sequence minimizes workpiece transit time within the production area.

Research indicates that optimizing machine layout can reduce handling time on production lines by approximately 15% to 20%, thereby enhancing overall production efficiency.

Additionally, the selection of machine tool configurations should be based on the workpiece’s dimensions, complexity, and production batch size.

For high-volume production, prioritize efficient automatic tool changers (ATC) and machining centers with automated loading/unloading capabilities.

These systems enhance output efficiency by minimizing downtime.

Data indicates that automated equipment can reduce downtime by 30% to 40%, improving equipment utilization and further boosting overall production capacity.

Optimizing machine tool configuration and layout not only boosts production efficiency but also effectively ensures workpiece quality and process continuity.

Automation Technology Applications

-

Automatic Tool Changer System

The Automatic Tool Changer (ATC) system enables rapid, automated tool changes during machining processes through an automated tool-changing device.

This reduces manual intervention and machine downtime.

In complex multi-process machining operations, particularly those involving different machined surfaces and materials, the ATC system shortens tool changeover time.

It typically requires only 2 to 3 seconds per change, whereas traditional manual tool changes are cumbersome and may take several minutes.

This time savings is particularly significant in high-volume production, reducing processing time per workpiece by up to 10% to 15% and substantially boosting overall production efficiency.

Furthermore, through tool magazine management, the ATC system automatically selects the most suitable tool for each operation based on programmed instructions.

This not only minimizes operator errors but also ensures optimal tooling for every process, enhancing cutting precision and surface finish quality.

An automatic tool changer system typically comprises components such as a tool magazine, manipulator, and control system.

In a typical machining center, the tool magazine can hold dozens of tools, ensuring all required tools are readily available during machining.

The manipulator rapidly locates and precisely retrieves the required tool from the magazine before installing it onto the spindle.

This process significantly reduces errors inherent in manual tool changes and guarantees precise tool switching during high-speed machining, resulting in a more stable and controllable manufacturing process.

The accuracy and speed of tool changes also positively impact the overall continuity of production line operations.

Depending on process requirements, the automatic tool-changing system can be flexibly programmed to configure tool arrangement and usage sequence, enhancing production efficiency and adaptability.

For multi-process, complex part machining scenarios, this system not only boosts productivity but also improves overall machining stability and quality consistency.

By reducing changeover time, minimizing human error, and optimizing tool selection, it has become an indispensable component in modern high-end manufacturing.

-

Online Inspection and Intelligent Control System

The online inspection and intelligent control system enables real-time monitoring of workpiece processing status.

It ensures all machining parameters meet predetermined requirements and promptly detects and corrects any deviations.

Typically employing high-precision measurement sensors and non-contact measurement equipment, the online inspection system continuously monitors critical dimensions, shapes, and surface quality of workpieces.

Through this approach, deviations in workpieces can be detected in real time and fed back to the control system for immediate adjustments, ensuring each workpiece meets design specifications.

The implementation of such systems significantly reduces defect rates, particularly in high-volume production.

By enabling real-time monitoring and correction, they minimize scrap caused by excessive deviations, typically lowering defect rates to below 2%.

The intelligent control system dynamically adjusts the machining process to optimize tool paths, cutting parameters, and machine tool trajectories.

This allows it to accommodate the machining requirements of different workpiece sections.

For instance, during complex surface machining, the system automatically adjusts cutting depth and feed rate based on real-time feedback data to minimize overcutting and tool wear.

This enhances surface finish and machining accuracy. It also extends tool life.

Data indicates that employing intelligent control systems can increase tool life by 15% to 30% and reduce workpiece surface roughness to below Ra 0.8 μm.

Furthermore, integrating online inspection with intelligent control systems significantly shortens processing cycles.

Traditional methods require removing workpieces from machines for offline inspection before proceeding to subsequent stages.

With the introduction of online inspection systems, part inspection and machining occur simultaneously.

This significantly reduces non-productive time in production and enhances production line continuity and efficiency.

Through deep integration with CAM software and CNC systems, the intelligent control system improves precision in complex machining.

It also enables flexible adjustments based on the overall operational status of the production line, ensuring consistent production efficiency and quality.

-

Equipment Maintenance and Real-Time Monitoring System

The efficient machining of high-end molds and precision machinery relies on advanced equipment and processes.

It also depends on the sustained optimal operation of machinery and the support of real-time monitoring systems.

Integrating regular equipment maintenance with real-time monitoring systems effectively enhances machine tool utilization.

It also minimizes downtime and ensures machining accuracy and consistency throughout production.

(1) Scheduled Equipment Maintenance

Scheduled maintenance should follow systematic and scientific principles to ensure long-term, efficient, and precise machine operation.

First, develop a detailed maintenance plan based on machine usage frequency, workpiece materials, and processing conditions, covering daily, weekly, monthly, and annual tasks.

Daily maintenance includes cleaning and lubricating critical components like spindles, guideways, and tool magazines to ensure smooth operation and minimize wear.

Weekly inspections should cover lubrication systems, hydraulic pressure, and coolant filters to guarantee effective temperature control and cooling.

Monthly maintenance requires calibrating spindle runout, tool clamping force, and positioning accuracy, along with electrical system safety checks.

Annual maintenance involves deeper diagnostics, such as replacing worn components and calibrating machine precision.

These measures help prevent failures, extend equipment lifespan, and maintain machining accuracy and production stability.

(2) Application of Real-Time Monitoring Systems

Real-time monitoring systems provide instant feedback on equipment status during production, ensuring optimal operation.

Through sensors and data acquisition systems, critical parameters like spindle speed, feed rate, temperature, and vibration are monitored continuously.

This enables early detection of anomalies such as excessive vibration or temperature overshoots.

Monitoring data can be shared in real time with maintenance personnel via the CNC system.

This facilitates prompt corrective actions to prevent equipment failures from escalating into production stoppages or reduced machining accuracy.

Research indicates that implementing real-time monitoring systems reduces equipment downtime by 15% to 25% while significantly improving machining accuracy.

Furthermore, these systems integrate with intelligent maintenance platforms to analyze data and predict equipment failure trends, enabling proactive maintenance scheduling.

This prevents breakdowns during peak production periods, further enhancing overall production line efficiency and stability.

The application of real-time monitoring technology not only boosts equipment operational efficiency but also effectively safeguards production continuity and machining precision.

-

Lean Process Management

Lean process management achieves more efficient production by reducing waste, optimizing resource allocation, and enhancing process continuity.

It focuses on holistically optimizing every stage of the manufacturing process, including material usage, rational arrangement of processing steps, and production cycle control.

This approach improves production efficiency and product quality while lowering production costs.

This approach requires a comprehensive analysis of production flows to identify redundant and non-value-added steps, streamlining processes to minimize unnecessary time and resource wastage.

Typical lean measures include reducing workpiece handling and clamping frequency.

By rationally arranging operations and equipment layout, workpiece movement distances can be shortened by 10%–20%, thereby decreasing non-processing time.

Furthermore, adopting a “one-piece flow” production model shortens waiting times between processes while maintaining process continuity, enhancing production line responsiveness.

Process standardization is another crucial element of lean process management.

Standardizing critical operations and machining parameters ensures consistent machining precision and quality across different production batches.

Implementing standardized process flows typically reduces production error rates to below 2%, significantly improving product consistency and yield rates.

Combined with automation technology, lean process management creates a more stable and efficient operating environment for production lines.

This further enhances overall production efficiency and competitiveness.

Conclusion

Through product design optimization, process improvement, and CNC programming optimization, machining efficiency can be significantly enhanced.

Additionally, the rational application of tool selection and machine tool configuration contributes to this improvement for high-end molds and precision machinery.

The implementation of automation technologies such as automatic tool changers and in-line inspection systems effectively reduces downtime, improves production line continuity, and elevates product quality.

Regular equipment maintenance and real-time monitoring systems ensure the sustained high-efficiency operation of machine tools.

They also help prevent downtime caused by equipment failures and declines in machining accuracy.

Lean process management further enhances production efficiency and product consistency by eliminating non-value-added steps and optimizing resource allocation.

The integrated application of these methods significantly boosts a company’s market competitiveness and production capacity.