China CNC Milling » Blog » Experimental Analysis of Factors Affecting Drill Bit Service Life

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Twist drills serve as the most widely used cutting tools in hole machining, but they allow large dimensional deviations and exhibit unstable cutting performance.

With the popularization of smart manufacturing technology, users require a stable minimum limit value for twist drill life, and low product life variability is a basic requirement for users.

As our flagship product, user feedback plays a guiding role in improving the performance of twist drills.

With the widespread adoption of smart manufacturing technology, the demand for consistency in drill bits has gradually increased, while users also place higher demands on the service life of twist drills. Identifying the factors affecting drill bit lifespan and steadily improving its service life is an urgent task for our factory at present.

Based on this situation, we selected a standard drill bit from our factory and conducted an in-depth analysis of the key factors influencing its lifespan.

Comparison Plans

Based on the properties of commonly used materials in the market, we formulated the following four comparison plans for this test without changing the tool material:

① Same tool base, different surface treatments, to analyze differences in tool life.

② Same workpiece material, different blank hardness, to analyze differences in tool life.

③ Same surface treatment method, cutting different materials, to analyze differences in tool life.

④ Other details affecting tool life.

To avoid errors from tool manufacturing affecting the cutting test results, we imposed uniform requirements on the geometric parameter consistency of the sample tools during testing.

We also preferred values that fall closer to the middle of the tolerance range.

All sample tools undergo heat treatment and surface treatment in the same furnace, and we define drill bit failure as extreme wear.

Experimental design

» Tool Life with Different Surface Treatments

The machinery manufacturing industry widely uses 40Cr material as a typical steel, and its properties represent those of most alloy structural steels.

In this scheme, the workpiece material has a quenched and tempered hardness of 200–220 HBW (hereinafter referred to as 40Cr soft material).

Tool samples include drill bits with two surface treatment methods: steam treatment and coating (TiN) treatment.

> Cutting Parameters and Test Conditions

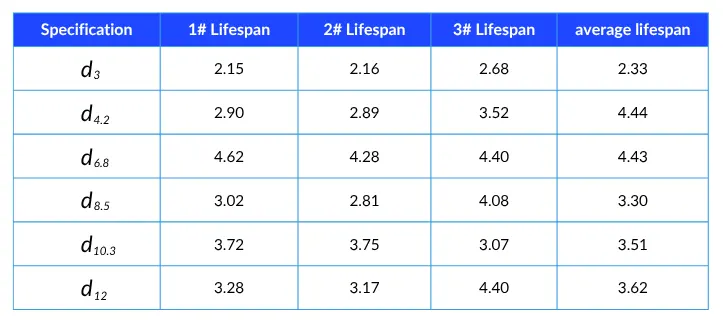

We selected six drill bit specifications—d3, d4.2, d6.8, d8.5, d10.3, and d12—and chose three pieces of each specification for cutting, totaling 36 pieces.

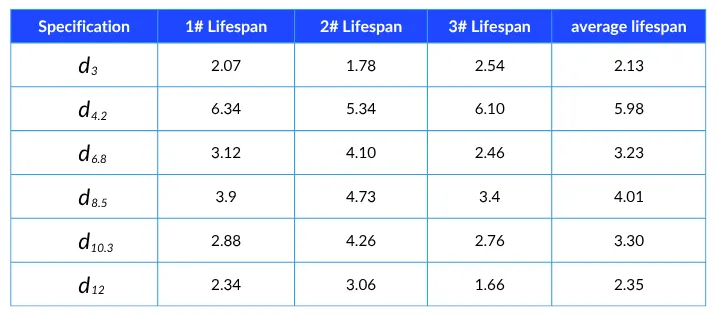

Now, We set the cutting depth to 3D and the linear speed to 25 m/min. Table 1 shows the test results for the surface steam-treated sample tools;

We set the cutting depth to 3D and the linear speed to 32 m/min. Table 2 shows the test results for the surface-coated (TiN) sample tools.

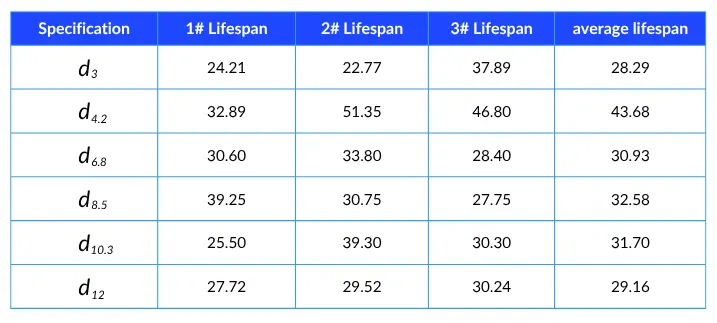

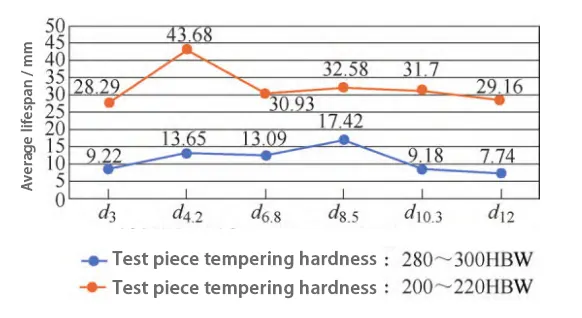

Figure 1 compares the average tool life under different surface treatment methods.

> Tool Life and Performance Comparison

As shown in Figure 1, the average service life of steam-treated sample tools ranges from 2 to 6 meters, while that of surface-coated (TiN) sample tools ranges from 28 to 44 meters.

Compared to steam-treated tools, surface-coated (TiN) tools exhibit an average service life improvement of 7 to 13 times.

Under the same substrate conditions, the service life of TiN-coated tools significantly exceeds that of steam-treated tools.

Due to the protective coating, coated tools are more heat-resistant than steam-treated tools, with rotational speeds approximately 25% higher than those of steam-treated tools.

During testing, since steam drills are not suitable for higher cutting parameters, a linear speed of 32 m/min accelerates drill bit wear.

Therefore, from the perspective of cutting efficiency, the processing efficiency of coated drills is significantly higher than that of steam drills.

» Tool Life Differences When Workpiece Materials are the Same but Blank Hardnesse are Different

Based on the recent trends in workpiece conditions, to achieve better mechanical properties, the hardness of workpieces has been increasing, with quenching and tempering hardness generally exceeding 280 HBW.

Based on the test results in Section 2.1, it is evident that coated tools hold greater research significance.

Therefore, this study adopts coated tools, with drill bit specifications as previously specified.

The workpiece material is 40Cr, with quenching and tempering hardness ranging from 200–220 HBW and 280–300 HBW (hereinafter referred to as 40Cr hard material).

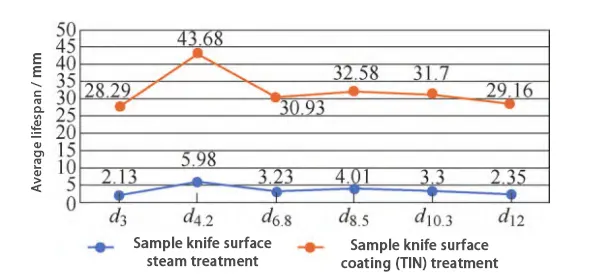

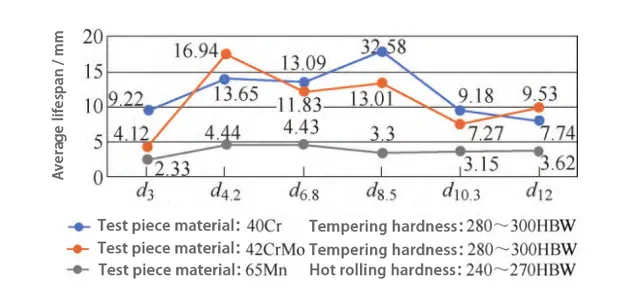

When we set the cutting depth to 3D and the linear speed between 25 m/min and 32 m/min, Table 3 shows the test results for the 40Cr hard material, and Figure 2 illustrates the average service life comparison.

In Figure 2, the service life of the coated drill when cutting 40Cr soft material is 28–44 m, and when cutting 40Cr hard material, it is 7–18 m.

The material hardness has increased by over 30%, and the drill bit service life has decreased by over 60%. During the development of this solution, we also tested steam drilling on 40Cr hard material, and its service life did not exceed 0.5 meters.

This indicates that steam drilling is only suitable for soft materials and not for materials with higher hardness.

» Difference in Tool Life When Cutting Different Materials with Tools that have the Same Surface Treatment

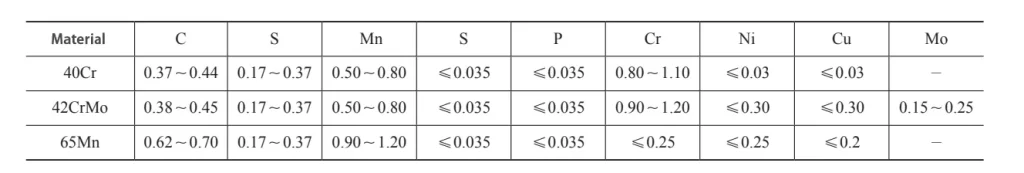

The tensile strengths of 40Cr, 42CrMo, and 65Mn are 810 MPa, 1080 MPa, and 735 MPa, respectively.

Table 4 compares the chemical compositions of the three materials. 40Cr has long been the primary cutting material for machining tests at major tool manufacturers, but in recent years, the variety of materials used in the mechanical manufacturing industry has increased significantly .

As shown in Table 4, the chemical compositions of 40Cr and 42CrMo are similar, but 42CrMo contains molybdenum, which enhances the steel’s hardness and wear resistance.

Performance Characteristics of 42CrMo and 65Mn

It is the material with the highest tensile strength and best load-bearing capacity among the three, and has largely replaced 40Cr in applications.

It is recommended to use this material for cutting tests, with a quenched and tempered hardness of 280–300 HBW. 65Mn, as a high-strength material, is widely used in certain specific fields.

Its carbon and manganese content is higher than that of 40Cr and 42CrMo, making it a material with relatively high strength, good toughness, plasticity, and excellent high-temperature mechanical properties.

However, due to its lower chromium content, it has poor quenching hardenability and lower tensile strength.

Therefore, we selected the material with a hot-rolled hardness of 240–270 HBW.

Cutting Test Results of Coated Drills on Different Materials

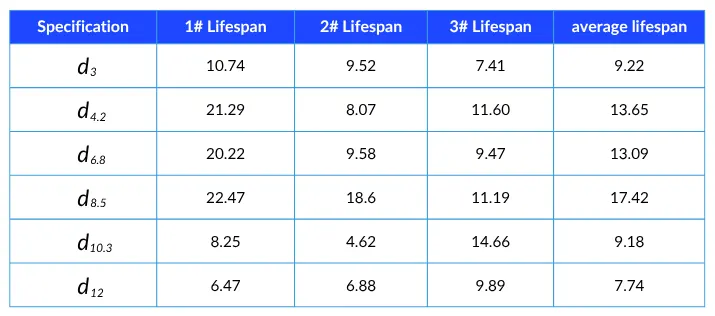

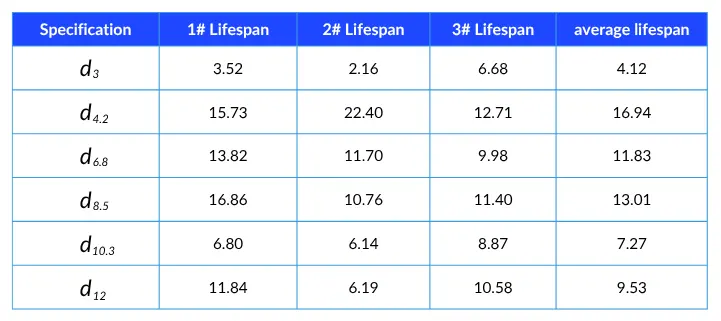

With a quenched and tempered hardness of 280–300 HBW, a cutting depth of 3D, and a linear speed of 25 m/min, Table 5 shows the test results for coated drill cutting of 42CrMo material;

When the hot-rolled hardness is 240–270 HBW, the cutting depth is 3D, and the linear speed is 25 m/min, Table 6 shows the test results for coated drill cutting of 65Mn material.

Comparative Analysis of Tool Life Across Materials

Figure 3 compares the average tool life of coated drill cutting for the three materials.

In Figure 3, the service life of coated drills when machining 42CrMo hard materials ranges from 4 to 18 meters.

Excluding the d3 specification, which has a shorter service life, the service life of other diameter drills varies significantly compared to that of coated drills when machining 40Cr hard materials.

The service life of coated drills when machining 65Mn material ranges from 2 to 5 meters, which is significantly more difficult to machine than 40Cr and 42CrMo, highlighting the poor machinability of 65Mn material.

Combined with relevant test results, this provides a basis for practical application.

» Other Details Affecting Tool Life

The above three schemes were all implemented under conditions where tool geometric parameters were relatively consistent.

However, in actual mass production processes, due to large-scale production and certain dimensional tolerances in the product drawings being relatively large, individual product dimensions may occasionally approach the limit deviations.

From the previous cutting results, even under conditions where dimensional deviations are well controlled, tool life still exhibits a certain degree of variability.

Test Scheme Targeting Geometric Deviations

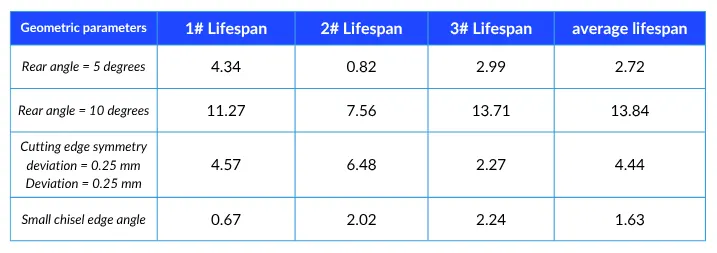

This scheme primarily addresses the impact of tool geometric deviations on tool life. The test tool selected is a coated drill, the workpiece material is 40Cr with a quenched and tempered hardness of 280–300 HBW, and the test tool specification is d12.

Since the dimensions prone to deviation are the rake angle, cutting edge symmetry, and cross edge, these three aspects were considered to select tools with larger dimensional deviations for cutting tests.

Influence of Rake Angle on Tool Life

When the quenched and tempered hardness is 280–300 HBW, the cutting depth is 3D, and the linear speed v = 25 m/min, the cutting test results for the d12 coated drill are shown in When the quenched and tempered hardness is 280–300 HBW, the cutting depth is 3D, and the linear speed v = 25 m/min, the cutting test results for the d12 coated drill are shown in Table 7.

As shown in Table 7, when the rake angle is 5°, the feed rate of the d12-coated drill is too high, severely affecting tool life.

When the rake angle is very small, the tool cutting edge and workpiece generate compression, leading to rapid tool wear.

Machining harder materials, the tool rake angle should not be too large.

When the rake angle is 10°, compared to the data for d12 in Table 3 (where the rake angle is approximately 14°), the tool performs more effectively.

Effects of Cutting Edge Symmetry and Cross Edge Deviation

When the cutting edge symmetry deviation reaches 0.25 mm, tool life is reduced, and the cutting edge becomes asymmetrical, causing uneven force distribution on both cutting edges.

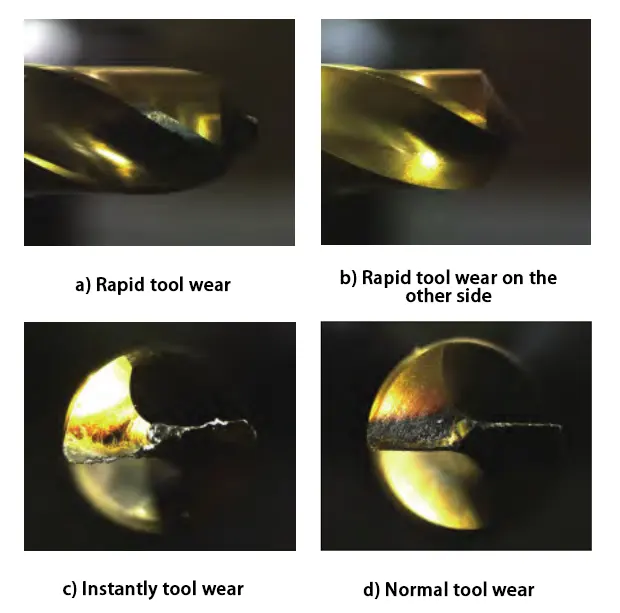

Tool wear is shown in Figure 4. Figure 4a shows the rapid wear state of the tool, with the coating on one side of the cutting edge peeling off quickly, leading to rapid tool wear;

Fig 4b shows the condition of the other side of the tool, where the transverse edge angle is smaller and the transverse edge Figure 4b shows the state of the other side of the tool, where the transverse edge angle is smaller and the transverse edge length is longer, increasing cutting resistance and causing unstable centering during cutting;

Figure 4c shows the state of severe tool wear, with the transverse edge wearing out first, leading to rapid tool failure;

Fig 4d shows the state of normal wear.

Summary of Factors Affecting Tool Life

Through the experimental analysis of the above four schemes, without considering the replacement of tool materials and taking into account the influence of machine tools, the factors affecting tool life are as follows.

(1) Surface treatment:

Steam drilling of 40Cr soft material has a service life of 2 to 6 meters. After coating treatment of the drill bit surface, the service life can be increased by 7 to 14 times, reaching 28 to 44 meters.

(2) Workpiece material hardness:

When the hardness of the workpiece material increases from 200–220 HBW to 280–300 HBW, the service life of the coated drill is only about 40% of the original. Steam drills are not suitable for materials with a hardness of 280 HBW or higher.

(3) Characteristics of the processed material:

There is little difference between the cutting performance of coated drills on 40Cr hard materials and 42CrMo hard materials, with a service life of 7 to 18 meters. The service life of coated drills on 65Mn materials is 2 to 5 meters.

(4) Drill bit geometric parameter deviations

When cutting harder materials, the rake angle should be closer to the lower tolerance limit.

Cutting softer materials, the rake angle should be closer to the upper tolerance limit.

When the rake angle is too small, the cutting edge of the drill bit is prone to squeezing against the workpiece, resulting in a significant reduction in drill bit life.

When the symmetry of the cutting edge is out of tolerance, it is easy for the coating on one side of the drill bit to peel off, shortening the tool life.

The dimensions of the cross edge are critical to drill bit lifespan; the larger the rake angle, the smaller the cross edge angle.

Conclusion

In this experiment, by analyzing the cutting performance of tools with different surface treatments when cutting the same material, the cutting performance of the same tool when cutting the same material but with different hardness, the cutting performance of tools with the same surface treatment when cutting different materials, and other details that affect tool life, the following conclusions can be drawn.

1) Coatings play a significant role in extending tool life, with notable effects in both soft and hard material cutting.

Steam-treated tools cannot be used for hard material cutting.

Coated grinding drills generally cost 20%–30% more than steam-treated grinding drills of the same type. From the perspective of improving cutting performance, coated drills offer better value for money than steam-treated drills.

2) When cutting different materials, the cutting performance of tools varies greatly.

Therefore, when selecting tools, it is necessary to be specific.

Tools cannot be used universally for materials with significant differences in performance, otherwise the cost-effectiveness ratio will be poor.

3) The geometric cross-sectional shape of the cutting tool, such as the rake angle, symmetry, and cross-edge angle, has a significant impact on the cutting performance of the tool.

In practical applications, it is essential to ensure that these parameters remain within reasonable limits to achieve optimal performance.

After analyzing the cutting tests conducted on this drill bit, we have provided guidance on several factors that affect drill bit life, which will help improve product life and quality.

After systematic cutting tests, this drill bit provides a basis for companies to select cutting parameters and estimate tool life, laying the foundation for improving the technical service capabilities of our factory.