China CNC Milling » Blog » Research on Process and Performance of Electric Brush Plating Sulfuric Acid Anodizing

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Aluminum and aluminum alloys possess high specific strength, excellent plasticity, superior electrical and thermal conductivity, outstanding machinability, and corrosion resistance.

They see widespread use across various industrial fields, particularly as non-ferrous metals in the aerospace industry.

However, issues such as low surface hardness, poor wear resistance, and susceptibility to localized corrosion severely limit their service life and performance in extreme environments.

Therefore, surface strengthening treatments for aluminum alloys—creating a high-hardness, wear-resistant, corrosion-resistant coating firmly bonded to the substrate—remain a critical research focus in surface engineering.

Sulfuric Acid Anodizing as a Mature Surface Treatment Technology

Among numerous surface modification techniques, anodizing, particularly sulfuric acid anodizing, stands as the most mature and widely applied electrochemical surface treatment for aluminum and aluminum alloys.

This process generates a dense, porous Al₂O₃ oxide film on the aluminum alloy surface.

The resulting anodized coating not only shields against corrosive media but also provides excellent corrosion resistance or enhances adhesion for subsequent painting.

However, during actual production and assembly, components may develop dimensional deviations, suffer impact damage, or be assembled with precision fits that prevent disassembly.

This precludes full-tank reprocessing. To overcome the limitations of traditional tank anodizing, sulfuric acid brush plating

This technique enables localized sulfuric acid anodizing to repair surface damage, ensuring product performance while minimizing economic losses from scrap and delivery delays.

Development and Application of Brush Plating Sulfuric Acid Anodizing

Brush plating represents a specialized advancement in electroplating technology.

Both domestically and internationally, industries employ it for localized coating restoration, replating, and even equipment remanufacturing.

Brush plating excels at rapidly repairing scratches on aluminum alloy surfaces.

Inspired by this, integrating brush plating principles into the anodizing process creates an advanced, well-designed, and comprehensive method.

Brush plating sulfuric acid anodizing enables selective anodizing of localized areas on aluminum alloy parts without requiring immersion tanks.

This paper investigates the brush plating sulfuric acid anodizing process, evaluating coating appearance, thickness, and corrosion resistance through testing.

It also demonstrates the application of brush plating sulfuric acid anodizing on localized areas of components within a manufacturing facility.

Basic Principles of Brush Plating Sulfuric Acid Anodizing

Fundamental Concepts

Brush plating sulfuric acid anodizing employs a technique similar to brush plating.

During anodizing, the tool serves as the cathode (negative electrode) while the part functions as the anode (positive electrode).

In the presence of an electrolyte (anodizing solution), localized areas on the aluminum surface form an anodic oxide film.

Specifically, aluminum acts as the anode in the electrolyte, losing electrons and combining with oxygen ions in the electrolyte to create the oxide layer.

Characteristics of Brush Anodizing

① Simple equipment setup without plating tanks, particularly suitable for localized brush coating on assembled products.

The brush anodizing solution contains no toxic components and causes minimal environmental pollution.

② Rapid film formation. Utilizing specialized solutions, brush sulfuric acid anodizing achieves speeds over twice as fast as tank plating, ensuring high efficiency.

③ Wide material applicability. Common aluminum alloys like 2A70, ZL101, and 6061 can undergo brush-applied sulfuric acid anodizing for repair.

④ Brush anodizing is only suitable for localized repairs and single-piece restoration.

For large-area or high-volume part repairs, its technical and economic performance falls short of immersion tank anodizing.

Electroplating Sulfuric Acid Anodizing Experiment

Materials and Reagents

The substrate material used was 2024-T3 aluminum plate with dimensions 3’‘ × 10’’ × 0.032”.

Its chemical composition (by mass fraction) was: Si 0.5%, Fe 0.5%, Cu 3.8%-4.9%, Mn 0.3%-0.9%, Mg 1.2%-1.8%, Cr 0.10%.

Five specimens underwent testing for coating appearance, thickness, and corrosion resistance.

The brush anodizing solution used was SIFCO Company’s XXX brush anodizing solution.

Water meeting HB5472 Class A standards was employed. The brush anodizing power supply utilized SIFCO‘s new anodizing brush plating power supply.

Brush-Applied Sulfuric Acid Anodizing Process Flow

The process flow for brush-applied sulfuric acid anodizing technology is as follows:

Organic solvent cleaning → Masking and protection → Establishing electrical contact with parts → Brush-applied sulfuric acid anodizing → Cold water rinse → Sealing → Cold water rinse → Air drying

Brush-Plated Sulfuric Acid Anodizing Process

The brush-plated sulfuric acid anodizing process steps shall be performed according to the tested process parameters. Current density: (0.5–1.0) A/dm², time: (15–20) min, temperature: (18–29) °C.

Remaining steps followed HB/Z 233 “Process Specifications for Sulfuric Acid Anodizing of Aluminum and Aluminum Alloys”: cold water rinse (1-3) min, sealing with (40-55) g/L K₂Cr₂O₇ aqueous solution, immersion at (90-100)°C for (15-20) min.

Finally, clean compressed air is blown onto the part surface until no visible water marks remain.

Test Methods

Inspectors evaluate the appearance of the sulfuric acid anodized coating applied by brush plating through visual inspection.

Thickness is measured using the MINTEST 4100 eddy current thickness gauge in accordance with ASTM B244 “Eddy Current Method for Testing Anodized Coatings”.

Corrosion resistance testing of sulfuric acid anodized coatings on electroplated brushes employs the neutral salt spray test method.

The neutral salt spray test was conducted using an SF-850 salt spray chamber in accordance with ASTM B117-2019 “Standard Test Method for Salt Spray Test.”

The salt solution concentration was 5% ± 1%, with a pH value of 6.5–7.2. Continuous spraying was maintained for a duration of 336 hours.

Results and Discussion

Appearance of Brush-Plated Sulfuric Acid Anodized Film

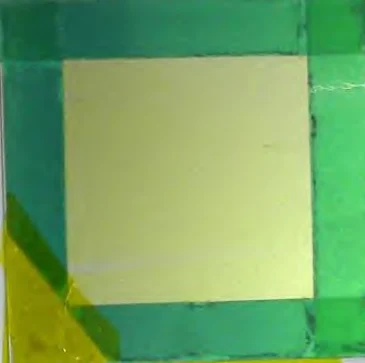

The appearance of the potassium dichromate-filled brush-plated sulfuric acid anodized film is shown in Figure 1.

The film exhibits a light yellow color, with a continuous, uniform, and complete coating.

The test uses a salt solution concentration of 5% ± 1% with a pH value of 6.5–7.2, and technicians perform continuous spraying for 336 hours.

Overall, the appearance of the sulfuric acid anodized coating produced by brush plating shows no visually discernible differences compared to that produced by tank anodizing.

The appearance complies with HB 5055 “Quality Inspection of Sulfuric Acid Anodized Coatings on Aluminum and Aluminum Alloys.”

Thickness of Brush Anodized Film

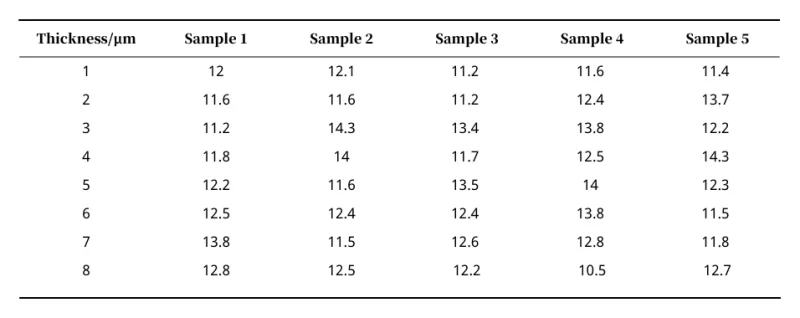

When measuring film thickness using an eddy current thickness gauge, the results are shown in Table 1 below.

The film thickness ranges from 10.5 to 14.3 μm, indicating good overall uniformity of the anodized film thickness.

This thickness also complies with the 4-25 μm requirement specified in HB 5055 “Quality Inspection of Sulfuric Acid Anodized Film on Aluminum and Aluminum Alloys.”

Corrosion Resistance of the Anodized Layer

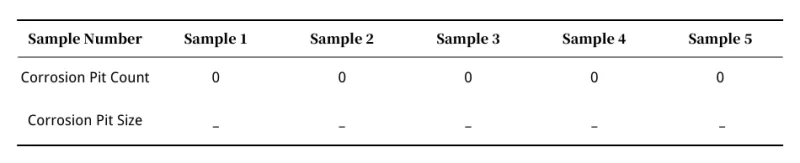

Technicians conducted corrosion resistance testing of the sulfuric acid anodized layer on the brush using a neutral salt spray test in accordance with ASTM B117.

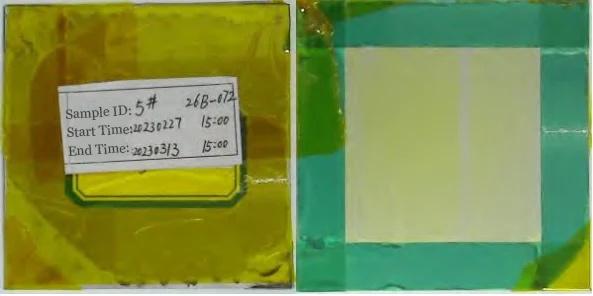

Table 2 presents the test results.The results indicate that no corrosion spots appeared on the specimens after 336 hours of salt spray exposure (as shown in Figure 2), demonstrating excellent corrosion resistance.

This performance meets the requirements for localized repair of aluminum alloy components.

Application of Brush Plating Anodic Oxidation Repair Process

Case 1:During incoming inspection in the product machining workshop, inspectors identified noticeable scratches on one end face of the part.

Due to multiple precision dimensions on the part, direct re-machining for overall rework was not feasible.

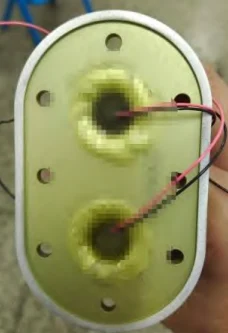

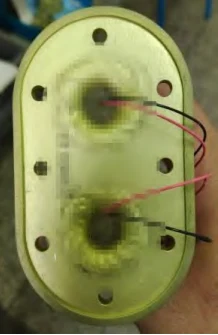

The machining department polished the affected end face, followed by repair using the sulfuric acid anodizing process with brush plating (as shown in Figures 3-4).

Case 2: Prior to final assembly submission, a visual inspection revealed black spots and scratches on an exposed end face.

Since the product had already undergone adhesive bonding and technicians had installed internal signal sensors, they could not disassemble it for repair.

Technicians repaired the defect using brush anodizing technology (as shown in Figures 5–6).

For localized anodizing on specific parts, they implemented the repair process as follows:

①Organic solvent cleaning. Wiped the polished area with a clean cotton cloth dipped in anhydrous ethanol to remove oil contamination from the machining process.

② Masking protection.

③ Brush sulfuric acid anodizing.

④ Potassium dichromate filling. Immersed the part in a potassium dichromate sealing solution for 20 minutes.

⑤ Cold water rinse and drying. After filling, rinse the parts with Class A water, then dry using clean compressed air.

⑥ Film quality inspection. The results of the brush-plated sulfuric acid anodizing repair are shown in Figures 4 and 6.

The film is uniform and fine, with no noticeable color difference from the original anodized film. It meets the product’s appearance quality requirements.

Conclusion

① The appearance and thickness of the oxide film produced by the brush-plated sulfuric acid anodizing process meet technical requirements, with no corrosion observed after 336 hours of neutral salt spray testing.

② Components repaired using the brush-plated sulfuric acid anodizing process satisfy product appearance quality standards.

③ The brush-plated sulfuric acid anodizing process aligns with the development direction of surface treatment production units and holds broad application prospects.