China CNC Milling » Blog » Digital Twin–Driven Optimization for Intelligent Manufacturing of Die-Cast Aluminum Parts

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

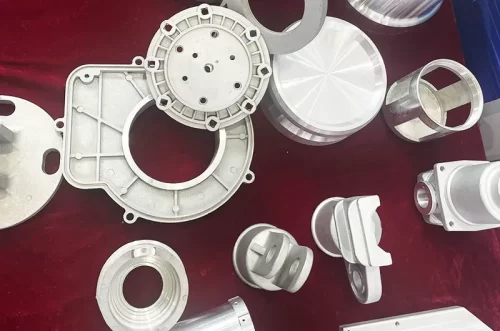

The demand for lightweighting in new energy vehicles has accelerated the adoption of large-sized aluminum die-cast components.

However, challenges remain. These include stringent dimensional consistency control across multi-process machining and isolated production line information.

Together, these factors constrain manufacturing efficiency and limit quality improvements.

This study focuses on the lower shell of battery trays, addressing core challenges such as machining error propagation, logistics imbalance, and process parameter inconsistencies.

We construct an integrated optimization model spanning multiple processes and systems, and we propose a digital twin solution that combines physical modeling with intelligent algorithms.

This approach aims to achieve synergistic improvements in multi-process machining quality and production line efficiency.

It also advances the implementation of smart manufacturing in the production of complex structural components.

Analysis of Multi-Process Intelligent Production Line System for Die-Cast Aluminum Parts

Analysis of Typical Parts and Their Full Process Flow

The selected lower shell of a new energy vehicle battery tray features thin walls, high ribs, and numerous hole patterns, demanding stringent flatness and positional accuracy with compressed GD&T tolerance ranges.

ADC12 high-pressure die-cast blanks first enter the automated storage and retrieval system (AS/RS).

AGVs then transport them to the workstations. The blanks then undergo a series of sequential processes.

These processes include plasma cleaning and FSW-C10 rib welding.

They also include multi-surface milling and drilling using FANUC BROTHER S700 machines, robotic deburring, and high-pressure spray cleaning.

In addition, operators reshape and correct the parts, then fully inspect them using coordinate measuring machines (CMMs).

Qualified parts are scanned and returned to storage.

The entire line operates with high automation, synchronizing physical and data flows in a closed loop.

This enhances link integrity and operational stability while improving dimensional consistency, cycle time matching, and overall yield.

Key Process Node Characteristics and Challenges

Die-cast blanks exhibit uneven initial residual stress distribution, accompanied by porosity and hard spots, which induce subsequent deformation and machining errors.

FSW introduces high heat input and applies intense plastic stirring, causing microstructural changes in the weld and heat-affected zone.

Concentrated newly generated residual stresses amplify local deformation and compromise structural stability.

CNC machining forces, cutting heat, and clamping forces act together on thin-walled sections. This interaction weakens structural rigidity.

It also induces elastic deformation and stress-release springback.

As a result, it becomes difficult to maintain hole position accuracy and reference surface accuracy.

Errors from these three processes exhibit nonlinear amplification, with dimensional deviations coupling and accumulating.

This hinders stable control and optimization modeling of the process chain.

At the production line level, these characteristics amplify scrap risks and prolong machine setup time, presenting core challenges requiring urgent resolution.

Identifying Critical Issues in Production Line Operations

Production line operations suffer from deep-seated problems such as non-integrated information systems and broken data transmission chains.

Non-standard equipment, such as cleaning and forming machines, lack unified communication interfaces.

As a result, their status and process data remain disconnected from the MES platform.

This reliance solely on manual recording disrupts information flow.

AGV scheduling fails to respond in real time to workstation cycle times.

This leads to work-in-process accumulation before critical processes.

It also causes imbalanced material flow and disrupts the production line rhythm.

Barcode scanning provides only superficial traceability.

It lacks real-time binding of processing parameters and environmental variables.

As a result, root cause analysis capabilities for defects remain weak.

The absence of a production visualization system across the entire line makes it difficult to obtain core KPIs like OEE, yield rate, and bottleneck load rate in real time.

Operators delay production instruction decisions and rely heavily on experience-based judgment.

Construction of a Digital Twin System for Smart Production Lines Optimized for Integration

Overall System Architecture Design

The digital twin system for smart production lines employs a four-layer architecture spanning from the physical layer to the application layer.

This architecture enables cross-layer mapping and closed-loop control.

The underlying physical layer comprises FANUC machining centers, FSW-C10 friction stir welding machines, AGV scheduling, multi-source sensors, and PLC nodes.

These components generate raw data in real time.

The edge/network layer deploys 5G URLLC industrial gateways and edge computing nodes, leveraging MEC for low-latency preprocessing of collected data to reduce uplink load.

The platform layer builds a production-line-level digital backbone based on a unified data model.

It integrates MES, APS, and PHM modules to correlate and unify multi-source heterogeneous data.

This data includes equipment status, process parameters, material information, and work instructions.

The application layer integrates a digital simulation modeling engine, optimization decision algorithms, a 3D visualization platform, and KPI dashboards.

It leverages a rule engine to execute event-driven responses.

The system employs standardized OPC UA and MQTT interfaces throughout to connect heterogeneous devices.

These interfaces provide unified data and computational support for dynamic modeling, process traceability, and algorithmic closed-loop control.

Part-Process Digital Twin Modeling

The core objective of the part-process digital twin model is to predict the final part geometric deviation with high fidelity.

This prediction accounts for the cumulative effects of multiple manufacturing processes.

Centered on part geometric accuracy prediction, the model employs finite element methods to multi-layer couple residual stresses, welding heat-affected zones, and CNC cutting loads.

In the initial stage, the residual stress field σcast is exported from casting simulation (ProCAST) and mapped to establish the initial state of the finite element model.

During welding, the FSW process utilizes thermo-mechanical coupling simulation to generate the σweld field.

For CNC machining, material removal is simulated using the Element Death technique, defining the dynamic cutting zone load field Fcut via the Johnson-Cook model.

The total deformation displacement δtotal at key feature points is modeled as expressed in Equation (1):

.jpg)

In the equation: f(σ) represents the deformation function caused by stress relaxation;

G(r) denotes the Green’s function of the workpiece-fixture system flexibility;

Fcut is the cutting force, dependent on cutting speed vc, feed per tooth fz, and cutting depth ap;

V is the removed volume; α, β, γ are weighting coefficients extracted through calibration experiments.

Upon inputting process parameters, this model enables real-time simulation of geometric deviations in part features, such as surfaces and hole positions.

It also provides data feedback for multi-process chain optimization.

Table 1 details the key input parameters for the finite element model.

| Input Parameters | Type | Value/Model | Data Source |

|---|---|---|---|

| Material Constitutive Relations | Johnson-Cook Model | A, B, n, C, m | Material Mechanics Experiment |

| Initial Residual Stress Field | Node Stress Field | Non-uniform Distribution | Simulation (ProCAST) |

| Heating Input | Heat Flow/Power Density | Heat Density Model | FSW Heat Source Model |

| Cutting Load | Distribution Field | Three-dimensional Cutting Force Function | Cutting Process Experiment |

| Workpiece-Tool Contact Model | Contact Friction Model | μ = 0.15 | Engineering Standard/Experimental Test |

Production Line-Logistics Process Digital Twin Modeling

The production line-logistics process digital twin model leverages discrete event simulation principles to construct a high-fidelity digital mirror within the FlexSim environment.

It aims to frame-by-frame replicate and continuously optimize the dynamic operational logic and material flow efficiency of the production line.

Core Model Elements

The model’s core lies in its atomic-level characterization of all on-site logical object attributes and behaviors:

We abstract key equipment, such as vertical machining centers and FSV friction stir welders, as Processors.

Their processing cycles, Mean Time Between Failures (MTBF), and Mean Time to Repair (MTTR) are set based on distribution fitting using three years of maintenance and production history data.

We encapsulate automated storage systems as capacity-constrained queues, which dynamically report storage occupancy rates and inbound/outbound blocking probabilities.

AGVs function as task executors.

Their linear and turning speeds, battery capacities, opportunistic charging thresholds, path network topologies, and traffic control logic are segmentally encoded.

This enables coupled simulation of power, task, and path dynamics.

During system operation, the model continuously tracks work-in-process (WIP) accumulation height, dwell time, and bottleneck propagation paths across workstation buffers.

It can pinpoint production line bottlenecks within seconds.

Queue Length Prediction and System Optimization

To quantify and predict queue lengths at bottleneck processes, the model incorporates a WIP level prediction algorithm based on queueing theory.

For simplified M/M/1 scenarios, the average queue length Lq is still calculated using the formula (2):

.jpg)

.jpg)

In the formula: Lq represents the average number of parts waiting for processing in the buffer zone; ρ denotes the equipment utilization rate; λ indicates the average arrival rate of parts at the workstation (determined jointly by upstream process output and AGV scheduling); μ signifies the average service rate of the workstation (i.e., the reciprocal of the processing cycle time).

By fine-tuning the AGV scheduling strategy (adjusting arrival rate λ) or iteratively optimizing the in-process manufacturing techniques (enhancing service rate μ), the high-fidelity digital twin model simulates the evolution curve of the waiting queue length Lq in seconds.

It issues early warnings before material flow congestion occurs on the physical production line, quantitatively providing optimal AGV quantity, path, and takt time matching solutions.

This delivers explainable, actionable decision support to planners.

It serves as a critical digital tool for continuously improving line OEE while reducing work-in-process inventory and energy consumption.

Multi-Objective Integrated Optimization Strategy for Production Line Systems

Establishment of Multi-Objective, Multi-Level Optimization Models

For production line-level system integration optimization problems, a multi-objective, multi-level optimization model coupling process and system layers is constructed.

We define the objective function as a two-dimensional vector that measures machining accuracy and production line efficiency.

Machining accuracy is modeled using the δ_total function, which reflects the cumulative effect of key feature geometric errors.

We evaluate system efficiency using OEE as the core metric, which assesses overall equipment performance.

The decision variable vector X encompasses toolpath planning parameters (e.g., cutting speed vc, feed rate per tooth fz, cutting depth ap) and the AGV scheduling rule set RAGV, which controls material flow takt time and waiting allocation strategies.

The optimization problem is modeled as Equations (3) and (4):

.jpg)

.jpg)

In the equation: X = [vc, fz, ap, RAGV, …]; T is the decision variable vector; δtotal(X) and OEE(X) represent the predicted deformation and production line efficiency from the digital twin model, respectively; constraints include spindle motor power Pmotor, machined surface roughness Ra, and tool life Tlife, which must satisfy their respective process and equipment limitations.

Hybrid Intelligent Algorithm Based on Digital Twins for Solving Problems

For high-dimensional, nonlinear, multi-objective optimization models, this paper proposes a solution framework driven by a digital twin engine.

The framework uses the Non-Dominated Sorting Genetic Algorithm II (NSGA-II).

It embeds a real-time twin system into the fitness evaluation process.

The algorithmic steps are as follows: First, multiple initial populations encompassing process and logistics parameters are randomly generated.

For any chromosome (decision variable X), the part-process twin module is activated to compute δtotal, while the production line-logistics twin module is triggered to evaluate OEE.

We perform non-domination sorting and crowding estimation based on the dual objective values.

After we select, crossover, and mutate, the offspring propagate through iterative cycles until they converge.

The final output is not a single solution but a Pareto frontier: each point represents a quantitative trade-off where improving one metric inevitably compromises another.

This provides decision-makers with a set of equivalent-performance, twin-validated alternative process solutions.

Conclusion

This study constructed a multi-layer digital twin spanning manufacturing and logistics, coupling a genetic algorithm to simultaneously suppress deformation and enhance efficiency.

Experimental validation demonstrates significant improvements in geometric accuracy, cycle time reduction, and equipment utilization.

Through real-time modeling, early warning, and feedback, the system delivers scientifically grounded solutions for multi-objective process decision-making.

This elevates production line intelligence.

Future applications will extend to complex irregular parts and large-scale mixed-flow production lines.

They will deeply integrate AI self-learning optimization engines to continuously enhance manufacturing system resilience and flexibility.

Together, these developments advance a new paradigm of adaptive, self-evolving intelligent manufacturing.