China CNC Milling » Blog » Design of Injection Molds for Electrical Outlet Housings

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

With the rapid development of the global economy, the power industry has also achieved remarkable progress. The widespread application of electrical equipment has effectively promoted the reform and improvement of power mechanisms.

As the direct protective tool for internal components of electrical equipment, the equipment housing not only provides effective protection but also enhances the aesthetic appeal of electrical equipment.

Among these, high-voltage connectors are critical electrical components widely used in the new energy sector.

Some experts and colleagues used ABAQUS software to construct a mold temperature field numerical simulation and concluded that mold surface dimensions influence deformation values for different materials.

Existing mold materials exhibit shortcomings in corrosion resistance, lightweight properties, and mechanical performance, coupled with inefficient pouring systems.

This paper proposes a mold design solution based on carbon fiber composite materials for high-voltage connector socket housings.

By optimizing the horn-shaped submerged gate and cooling system, it achieves high-pouring efficiency and long-life mold manufacturing.

High-Voltage Connector Socket Housing Mold Structure Design

Housing Structure

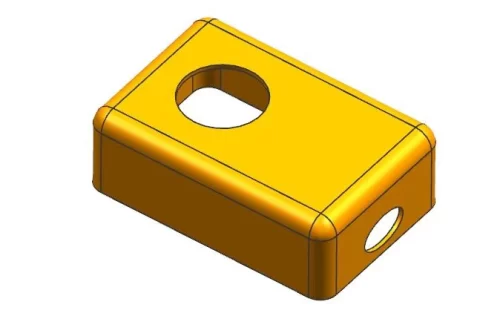

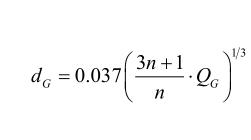

The high-voltage connector socket housing, as shown in Figure 1, primarily consists of an upper and lower layer structure.

Its overall dimensions are 50mm x 55mm x 40mm, with the housing thickness ranging between 1-5mm.

The plastic part features a draft angle during demolding, typically set at 1.5°.

Casting System

The team selected a four-cavity mold configuration for the mold cavity and employed a horn-type submerged gate.

The machine completes the entire material feeding process through a single gate.

Engineers optimized the horn-type submerged gate into an insert structure to facilitate melt formation.

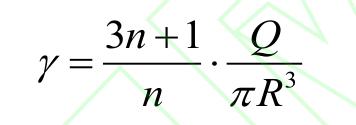

The plastic part is ejected from the mold by the action of the ejector pin. The shear rate without gravitational constraints is:

γ represents the shear rate of molten material flow, based on the power-law fluid constitutive equation, with a range of 1000–5000 s⁻¹.

Q denotes the molten material volumetric flow rate, determined by injection molding machine parameter calibration.

n indicates the molten material’s gravity-free index, influenced by molten material temperature and γ, obtained via capillary rheometer.

R denotes the runner radius, based on Moldflow runner design specifications, with a range of 2–4 mm.

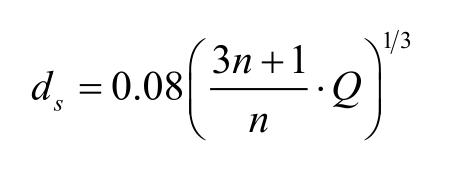

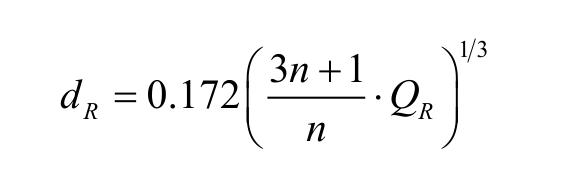

During main runner diameter calculation, the formula for the main runner diameter in the gating system is:

ds denotes the diameter of the circular main runner, typically ranging from 4 to 8 mm.

Q represents the molten metal volumetric flow rate, while n indicates the molten metal’s non-gravity-restricted index.

The formula for calculating the diameter of the runner system’s branch runners is:

Here, dR denotes the diameter of the runner cross-section, typically not exceeding 8 mm.

QR describes the volumetric flow rate of molten plastic in the runner, while n represents the index indicating that the molten material is not restricted by gravity.

The formula for calculating the cross-sectional diameter of the main gate is:

Here, dG denotes the cross-sectional diameter of the main runner gate.The value range adopted in this paper is 0.8–1.5 mm.

QG represents the molten metal volume fraction flowing through the gate, while n indicates the molten metal’s gravity-free index.

This completes the design of the pouring system.

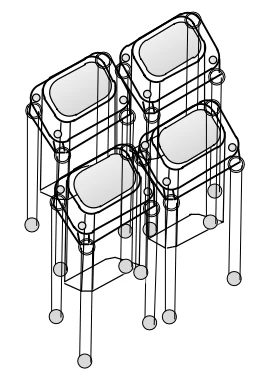

Cooling System

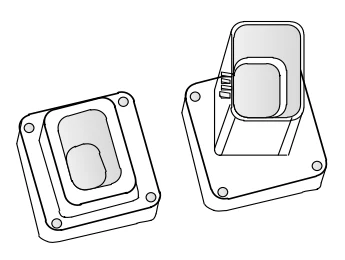

To enhance the cooling performance of electrical equipment housing molds, the fixed mold primarily employs a circumferential water channel configuration, while the moving mold utilizes a water well cooling channel layout.

The cooling system water channel arrangement is shown in Figure 2.

The circumferential water channels uniformly reduce cavity surface temperatures, minimizing warping deformation caused by uneven plastic part shrinkage.

The water well channels achieve localized rapid cooling, thereby shortening the molding cycle.

The cooling water channel diameter ranges from 9 to 13 mm, with a distance of 11 to 14 mm between the cavity and cooling water channels.

Engineers positioned the inlet and outlet pipes of the cooling water channels on the same side of the mold.

The system design requires determining the cooling water volume and the heat transfer area of the cooling water channels, as calculated by the following formula:

.jpg)

In the formula, G and Δτ represent the mass of molten plastic within the mold over a specified time period and the heat released during molding, respectively.

The heat released ranges from 1.9 to 2.1 J/(g·℃);

C, ρ, t₁, and t₂ denote the specific heat capacity, density, outlet temperature, and inlet temperature of the cooling water, respectively.

In this study, the outlet temperature ranges from 10 to 15°C, and the inlet temperature ranges from 15 to 25°C.

The heat transfer area of the cooling water circuit is:

.jpg)

A represents the thermal conductivity of the cooling water, which is set at 45 W/(m·K) in this study.

TW denotes the surface temperature of the molded plastic part (40–80°C), while TQ denotes the average cooling water temperature (25°C).

Engineers designed the cooling system by determining the cooling water volume and the heat transfer area of the cooling water circuit.

Cooperative Design of Core-Pulling Mechanism and Ejection System Based on Thin-Wall Features

Given the asymmetric thin-wall structure of the socket housing, traditional ejection systems often cause plastic part deformation.

To address this, this paper designs a core-pulling mechanism based on inclined guide blocks and sliders, combined with gap venting using flat and round ejector pins to ensure uniform force distribution during demolding.

The ejection system is shown in Figure 3. A snap-fit design exists on one side of the high-voltage connector socket housing.

Engineers must implement a side core-pulling structure to prevent snap-fit misalignment.

Engineers selected two inclined guide pins, each with a diameter of Ф8 mm and an inclination angle of 22°.

After arrangement, the pulling distance is 8mm, and the wedge angle is 23°. The shell thickness ranges between 1–5 mm.

When the shell layer thickness is 1 mm and height is 24 mm, four dome pins with a diameter of Ф3 mm are positioned at the mold parting line.

A flat ejector pin measuring 1 mm × 2 mm is added at the thinnest point of the socket shell’s lowest section.

Engineers added two flat pins to each of the three remaining surfaces of the socket housing, excluding the slider area.

The gap between the flat pins and the pins serves as an exhaust channel, facilitating rapid ejection of the socket housing plastic part.

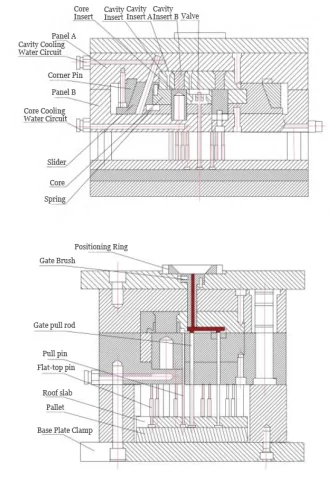

Overall Mold Structure

The LKM CI series mold base was selected for system integration, model number CI-2535-A60-B70-C80. The overall shell mold design is shown in Figure 4.

Engineers perform the demolding process using ejection pins arranged in an insert-type structure.

The mold incorporates components such as spring cores, sliders, core cooling water circuits, B plates, core inserts, flat ejector pins, gate pull rods, and locating rings.

Selection of Housing Mold Materials

Traditional metal molds, due to their heavy weight and poor corrosion resistance, struggle to meet the high-precision housing requirements of new energy equipment.

Therefore, engineers must explore lightweight composite materials.

Performance Advantages and Selection Criteria of Carbon Fiber Composites

Carbon fiber composites utilize polyacrylonitrile (PAN) as the precursor.

Through pre-oxidation, high-temperature carbonization, and graphitization, they form a graphite microcrystalline structure.

Reinforced with a resin matrix, they ultimately achieve high specific strength and corrosion resistance.

Carbon fiber exhibits external flexibility with internal rigidity, weighing less than aluminum yet surpassing steel in hardness while offering excellent corrosion resistance.

It represents the latest generation of reinforced fiber materials.

The carbon fiber composite selected for this study utilizes a bisphenol A epoxy resin matrix, primarily cured with methyl tetrahydrophthalic anhydride.

The resin-to-curing agent ratio is 1.176:1.

The fiber orientation employs a three-dimensional five-directional weave structure, which enhances material viscosity, promotes the glass transition temperature, and ensures reasonable mold shrinkage.

Corrosion Resistance

As core components of power systems, the electrical conductivity and current-carrying stability of high-voltage connectors directly depend on the protective capability of their socket housings.

Molds, serving as the primary tools for producing these housings, must not only exhibit high strength and corrosion resistance but also possess adequate modulus and lightweight characteristics.

Carbon fiber composite molds can operate reliably in diverse harsh environments without corrosion from acids, alkalis, salts, or other factors.

This enables socket housing production to overcome environmental constraints, significantly boosting production efficiency and extending mold service life.

Carbon fiber composites exhibit excellent high-temperature resistance.

As molten material enters the mold and surface temperatures rise continuously, the mold remains stable against deformation caused by heat, preventing dimensional deviations in the molded socket housing components.

Statistical Methods

Data from the experiments designed in this study were analyzed using SPSS 20.0.

Engineers expressed the quantitative data as the mean ± standard deviation.

Engineers analyzed changes in corrosion resistance potential using linear regression, considering P < 0.05 as statistically significant.

Experimental Analysis

Mold Dimensions and Injection Molding Machine Parameters

The high-voltage connector socket housing features a two-layer structure with overall dimensions of 50mm x 55mm x 40mm.

The outer wall thickness ranges between 1-5mm, with 1mm selected as the wall thickness and 25mm reserved for clearance.

The mold cavity dimensions are 100mm x 105mm x 85mm. The injection molding machine selected has an injection capacity of 620 cm³.

Equipment model: Sumitomo SE1800EV-A with a clamping force of 1800 tons.

Pouring Effect

The injection molding machine timer recorded the pouring time.

At a melt temperature of 220 °C and an injection pressure of 80 MPa, engineers extracted melt samples in real time.

Engineers measured the shear rate using a rotational rheometer (MCR302).

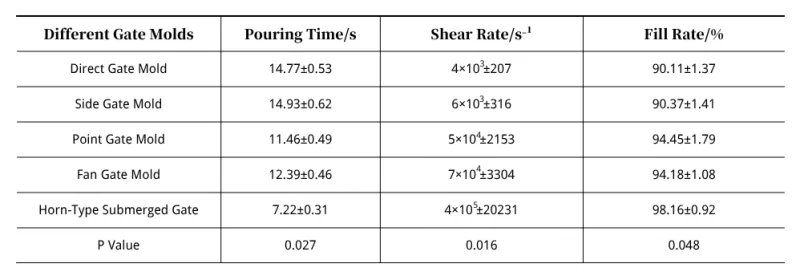

Table 1 compares the pouring processes. All experimental data represent the average of 10 repeatability tests.

The horn-type submerged gate exhibited the shortest average pouring time during the process at 7.22 ± 0.31 s.

The average melt shear rate for the horn-type submerged gate was 4 × 10⁵ + 20231 s⁻¹.

With the most ideal flow rate, the horn-type submerged gate achieved a filling rate of approximately 98%, demonstrating the most optimal mold pouring effect.

Researchers observed statistically significant differences (P < 0.05) among all indicators.

Corrosion Resistance Analysis

P20 mold steel offers ideal machinability and polishability, making it suitable for molds with complex cavities, though its hardness is generally moderate.

H13 mold steel not only withstands high temperatures but also exhibits excellent hardness after quenching and superior rust resistance.

Both P20 and H13 mold steels feature good machinability and heat treatment properties, commonly used in complex cavity molds and high-temperature forming applications.

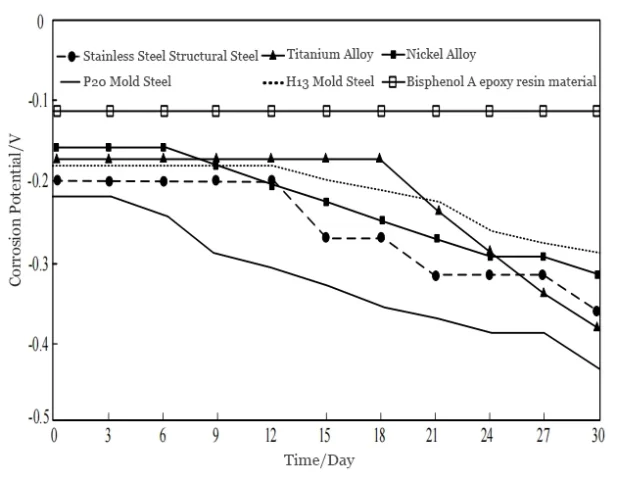

To validate the suitability of carbon fiber composites in humid and acidic/alkaline environments, compare their corrosion potential changes with those of metallic materials.

This study selected bisphenol A epoxy resin as the material for manufacturing high-voltage connector socket shell molds.

Nickel alloy, titanium alloy, stainless steel structural material, P20 mold steel, and H13 mold steel were respectively used to produce the high-voltage connector socket shell molds.

All mold preparations met industrial forming standards.

The molds were deployed in socket housing production and operated continuously for 30 days under acidic, alkaline, saline, and high-temperature conditions.

Engineers immersed the molds in electrolyte solutions every three days and measured their corrosion resistance through corrosion potential.

To ensure experimental reliability, engineers repeated this procedure ten times.

The corrosion potential changes are shown in Figure 5.

As time increased, the average initial corrosion potential of stainless steel molds exhibited a decreasing trend.

Among them, P20 and titanium alloy showed the greatest decline.

The average steady-state potential of carbon fiber composite materials was around -0.11V, significantly outperforming other materials.

This can effectively extend the service life of molds under harsh operating conditions.

Strength Analysis

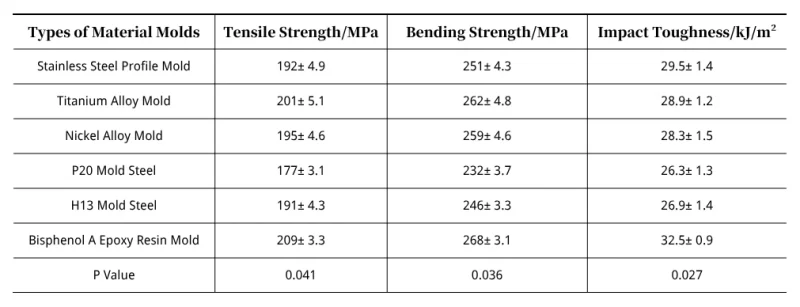

Tensile strength and flexural strength tests were conducted on molds made from nickel alloy, titanium alloy, stainless steel structural steel, and bisphenol A epoxy resin using a universal testing machine.

Researchers evaluated impact toughness using a pendulum impact tester.

Researchers repeated all experiments 10 times. Table 2 shows the mold mechanical property test results.

Regarding tensile strength, the bisphenol A epoxy resin mold exhibited the highest tensile strength at 209±3.3 MPa.

The stainless steel structural steel mold demonstrated the lowest flexural strength at 251±4.3 MPa.

For flexural strength, the bisphenol A epoxy resin mold exhibited the best performance at 268±3.1 MPa.

Additionally, the carbon fiber composite mold demonstrated the highest impact toughness at 32.5±0.9 kJ/m², indicating that carbon fiber composites possess ideal mechanical properties.

Differences were statistically significant (P<0.05).

The Effect of Carbon Content on Warpage and Service Life

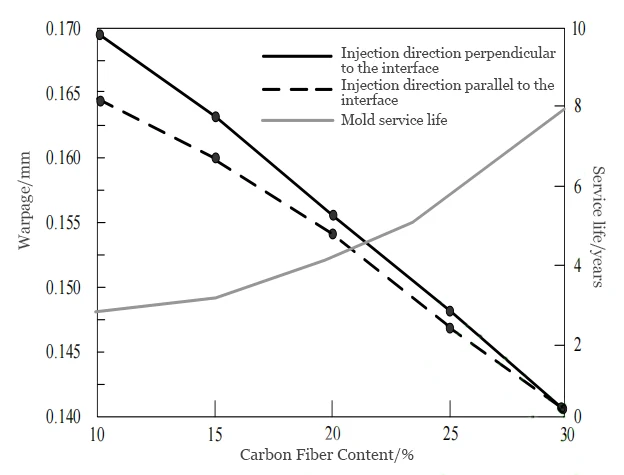

Different carbon fiber contents significantly influence the warpage of plastic parts and the service life of molds.

This study employed bisphenol A epoxy resin with carbon fiber contents of 10%, 15%, 20%, 25%, and 30%.

Under injection conditions of 260°C temperature, 48 cm³/s injection speed, and a carbon fiber aspect ratio of 25, assuming constant inter-fiber interaction coefficients.

The specific influence curves of carbon fiber content on part warpage and mold service life are shown in Figure 6.

Results indicate that warpage decreases with increasing carbon fiber content, while service life increases.

When carbon fiber content rose from 10% to 30%, warpage perpendicular to the injection direction decreased from 0.1689 mm to 0.1413 mm;

while warpage in the direction parallel to the mold surface decreased from 0.1649 mm to 0.1413 mm.

Mold service life extended from 2.8 years to 8 years.

Thus, increasing carbon fiber content significantly improves composite interface performance and effectively prolongs mold service life.

Conclusion

This paper addresses the issues of low pouring efficiency and insufficient material corrosion resistance in high-voltage connector housing molds by proposing an optimized design solution based on carbon fiber composite materials.

Experimental results demonstrate that the horn-type submerged gate reduces pouring time to approximately 7 seconds while increasing filling rate to 98.16%.

The corrosion resistance and mechanical properties of carbon fiber composites significantly outperform traditional metallic materials, offering new insights for designing high-precision, long-life electrical molds for socket housings.