China CNC Milling » Blog » Design and Application of a Downward-Pressing External Clamping Fixture for the Slide Table of a CNC Honing Machine

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Cylinder liners are core components of an engine, playing a crucial role in ensuring stable operation, enhancing performance, and extending service life.

Based on cooling methods, we can categorize cylinder liners into dry-type and wet-type.Wet-type liners provide several advantages.

Their outer walls are in direct contact with cooling water, which enables superior heat dissipation.

This direct contact also makes maintenance easier. Consequently, engineers widely use wet-type liners in engines such as diesel powerplants.

The inner wall machining primarily relies on honing processes. Equipment has evolved from manual single-feed conventional honing machines.

It then progressed to hydraulic dual-feed honing machines. Today, it has advanced to fully servo-controlled CNC honing machines. Throughout this evolution, automation and precision have continuously improved.

Against this backdrop, developing highly efficient honing fixtures has become a key challenge for cylinder liner manufacturers.

Design Background

Wet cylinder liners typically feature wall thicknesses ranging from 5 to 9 mm. Due to their relatively substantial wall thickness, deformation during honing operations is minimal.

Consequently, manufacturers predominantly design fixtures as shown in Figure 1 in conventional honing processes.

The outer diameter of the liner support shoulder serves as the locating feature. The cylinder piston performs clamping and releasing. The vertical movement of the piston is then used to drive the upper cover.

Advantages

Advantages of this traditional honing fixture include:

① Simple design and machining.

② Easy loading/unloading.

③ Easy switching between different specifications and varieties.

Disadvantages

The disadvantages are:

① Because diesel engine cylinder liners generally have an inner diameter of 90–150 mm, designers must make the clamping piston bore larger than the liner’s inner diameter.

This large piston bore is highly susceptible to scoring after frequent clamping and releasing actions, leading to hydraulic oil leakage and unstable clamping force.

② The clamping force acts entirely on the end faces, causing indentations that severely compromise appearance quality.

③ Oil leakage reduces clamping force, leading to cylinder sleeve rotation and defective products.

④ For products with thin cylinder walls (e.g., liner skirt thickness ≤ 3mm), this fixture causes deformation after machining.

Design of External Clamping Fixture for Rubber Sleeves

In traditional rigid clamping methods, the fixture makes direct contact with the end face or outer surface of the cylinder liner.

The fixture material has high rigidity and lacks surface cushioning. As a result, even minimal displacement deviations during clamping can cause damage to the cylinder liner surface.

Uneven clamping pressure can also easily lead to scratches, indentations, and other defects.

Such surface defects not only compromise the liner’s appearance but also degrade its surface quality.

In severe cases, they can render the cylinder liner unusable.

Rubber Sleeve External Clamping Fixture

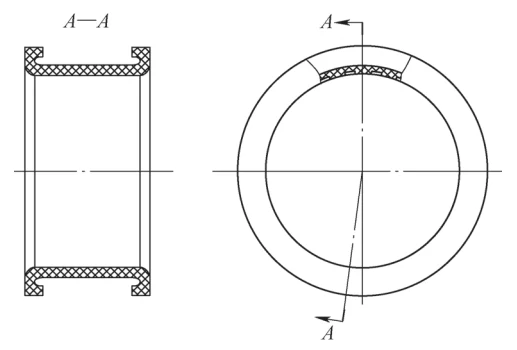

The fixture designed with an external rubber sleeve clamping configuration, as shown in Figure 2, effectively mitigates the aforementioned drawbacks.

The rubber material possesses excellent elasticity and flexibility. Fluid, such as hydraulic oil or cutting fluid, enters the upper and lower inner sleeves.

Fluid pressure then acts on the external surfaces of the upper and lower rubber sleeves. This pressure causes the rubber sleeves to expand inward and deform.

The rubber sleeves uniformly and gently grip the outer surface of the cylinder liner. Simultaneously, the expanding rubber sleeves distribute the force evenly across the cylinder liner surface, preventing damage from localized excessive pressure.

Working Principle

Place the cylinder liner 10 into the rubber sleeve’s external clamping fixture for machining. Use the lower end face of the cylinder liner’s support shoulder as the positioning reference.

Mate the outer circumference of the cylinder liner’s upper waist band with the inner bore of the pressure cap 11 as the mating surface.

As fluid continuously flows through the fluid inlet 4 and outlet 9, it gradually increases the external pressure on the upper rubber sleeve 8 and lower rubber sleeve 5.

Owing to the inherent elasticity of the rubber sleeve material (see Figure 3), it undergoes inward expansion deformation under external pressure.

This expansion generates a uniform and stable clamping force that acts uniformly across the cylinder liner surface.

After machining is complete, fluid discharge gradually reduces the external pressure on the rubber sleeves.

Because of their elastic memory, the rubber sleeves gradually return to their original shape and state once the pressure is removed.

When the rubber sleeves fully recover, they release the cylinder liner, leaving it in a free state.

At this point, operators can easily remove the cylinder liner from the external holding fixture, thus completing the entire single-cycle machining process for the cylinder liner.

Key Structural Considerations

1) Material selection for the rubber sleeve is particularly critical. Since our company uses cutting fluid as the working medium, we select EPDM rubber for the sleeve due to its high water resistance and corrosion resistance.

2) As the rubber sleeve is a wear part, clamping force should not be excessive.

It should only exceed the cutting force exerted by the grinding wheel on the inner surface of the cylinder liner during grinding.

Maintain clamping pressure between 0.4–0.5 MPa to prevent frequent sleeve damage caused by excessive force.

3) The 6 mm-thick rubber sleeve has a radial clearance of less than 5 mm relative to the cylinder liner’s outer circumference.

This prevents sleeve damage due to excessive clearance.

Advantages and Disadvantages of the Fixture

This fixture offers the following advantages:

① The clamping force remains stable, preventing displacement or vibration caused by cutting forces or vibrations during machining.

This ensures that the dimensional accuracy, surface roughness, and grid pattern parameters of the machined cylinder liners meet all specifications.

② It eliminates quality defects such as scratches or pressure marks caused by rigid tooling clamping on cylinder liners.

③ The rubber sleeve expands and contracts rapidly, enhancing operational efficiency.

The disadvantage is that operators must load materials into the fixture from the top down.

When machining larger and longer cylinder liners, loading and unloading requires significant physical exertion from operators, impacting production efficiency.

Improved Design

Some diesel engine models in large heavy-duty trucks, construction vehicles, and certain large buses feature large-bore cylinder liners in their design.

These liners typically have an inner diameter of 130–160 mm.Their length is approximately 300 mm. This design accommodates the high displacement and torque requirements of such engines.

These large-bore liners generally weigh more than 7 kg. Operators often load and unload them manually during honing operations.

This is especially demanding when one operator is responsible for multiple machines. Therefore, reducing labor intensity is essential to improve production efficiency.

Structural Design of the Slide-Down External Clamping Fixture

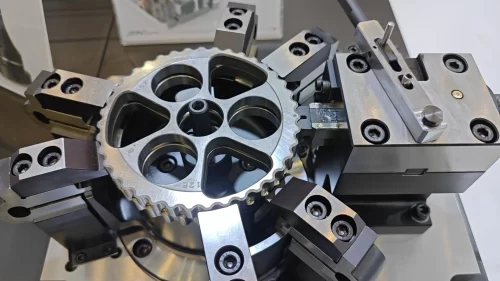

Experts have redesigned a slide-down external clamping fixture (see Figures 4 and 5). Its operating principle is as follows:

A slide lifting hydraulic cylinder 17 is mounted on the honing machine bed 18. This cylinder drives the slide support frame 14, moving the external clamping fixture vertically.

Linear guides 15 serve as the guiding components for the fixture, ensuring linearity and stability during movement.

The external clamping fixture is secured to the slide support frame 14 via a connecting sleeve 13.

The slide support frame 14 connects to the linear guide rail 15 through a linear guide block 16, enabling smooth sliding along the guide rail.

Workpiece Positioning and Locating Reference Scheme

The upper end face of the workpiece cylinder liner 8 is used as a positioning reference. The stepped bore end face of the locating ring 3 also serves as a positioning reference.

The outer circumference of the cylinder liner’s support shoulder mates with the stepped bore of the locating ring 3.

This interface functions as the mating surface.

Load the workpiece cylinder liner 8 onto the turntable at the machining station (see Figure 5) within the locating ring 3. Start the CNC honing machine.

The workpiece rotates clockwise by 180° together with the turntable.

Clamping, Honing, and Release Process

After this rotation, the lifting hydraulic cylinder 17 drives the slide support frame 14.

The outer clamping fixture then moves along the linear guide from top to bottom.

It continues moving until it reaches the preset limit position.

At this point, fluid simultaneously enters the upper inner sleeve 9 and lower inner sleeve 5 of the external clamping fixture through fluid inlets/outlets 6 and 10.

As fluid pressure gradually increases, the upper rubber sleeve 11 and lower rubber sleeve 7 begin to squeeze inward.

This action securely clamps the workpiece cylinder liner 8.As a result, reliable fixation is ensured during machining.

After the workpiece is securely clamped, the honing machine spindle 19 starts, driving the honing head into the cylinder liner.

Under system control, the honing head performs honing on the liner’s inner wall according to preset machining parameters, progressively achieving the required dimensional accuracy and other specifications;

Upon completion of honing, the honing spindle 19 retracts to its starting position.

Fluid simultaneously discharges through inlet/outlet ports 6 and 10, causing both upper and lower rubber sleeves 11 and 7 to gradually retract to their original state, releasing the workpiece.

The slide lift hydraulic cylinder 17 actuates again, driving the slide support frame 14 to move the external clamping fixture upward along the linear guide rails.

It returns to the initial upper limit position, concluding the entire single machining cycle and preparing for the next workpiece loading and machining operation.

Conclusion

In summary, the downward-pressing external clamping fixture for CNC honing machine slides offers significant advantages.

This is especially true for the rubber sleeve external clamping structure. It proves highly effective in cylinder liner honing operations.

Compared to traditional rigid fixtures, it completely resolves common industry issues such as wear and oil leakage in large hydraulic cylinders.

It also effectively prevents quality defects, including scratches and compression damage, which traditional fixtures often cause to cylinder liners.

In terms of machining outcomes, this fixture ensures core quality metrics such as dimensional accuracy, surface roughness, and pattern parameters after processing.

At the same time, it significantly boosts operational efficiency and reduces operator workload.

As the engine manufacturing industry continues to elevate demands for cylinder liner quality and production efficiency, such fixtures hold broad application prospects and promotional value.

They are poised to inject new vitality into industry development, propelling engine manufacturing toward higher quality and greater efficiency.