China CNC Milling » Blog » Cutting performance of cubic boron nitride composite Ti(C,N)-based metal-ceramic tools

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Preamble

As a composite material, cermet is prepared from ceramics and metal according to a certain method, so it has the advantages of both materials in terms of hardness, toughness, thermal conductivity and so on, and has been researched a lot.

Among these, Ti(C,N)-based cermet tools are widely used due to their superior hardness, wear resistance, chemical stability, and low coefficient of friction. These advantages have led to their increasing research and application in cutting tools.

Cubic boron nitride (CBN) possesses ultra-high hardness, and its atomic bonding and lattice constants are similar to those of diamond, making it an excellent cutting material.

Moreover, CBN exhibits strong resistance to chemical reactions with iron-group elements and their alloys, as well as high heat resistance, further enhancing its suitability for cutting tools.

As a cutting material for cutting tools, CBN is not easy to react with iron group elements and their alloys, and has higher oxidation resistance.

Meanwhile, when the temperature is increased, the thermal conductivity will be increased proportionally, so that the diffusion of heat can be accomplished rapidly in the cutting process to ensure the quality of the cutting process .

In this paper, two groups of Ti(C,N)-based cermet inserts with different cubic boron nitride (CBN) contents were prepared using the hot isostatic pressing sintering process.

A series of cutting tests were conducted, with cutting speed and feed rate as key parameters.

The performance stages of the tools made from different materials, along with the underlying wear mechanisms, were analyzed in depth.

Experimental Materials and Methods

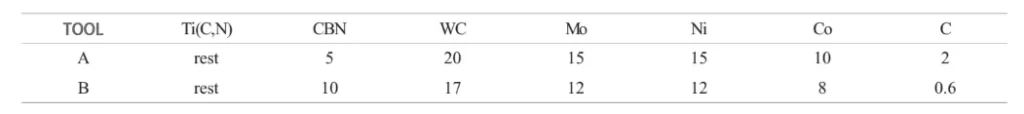

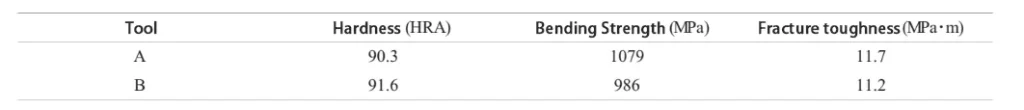

Micron-sized cubic boron nitride and micron-sized Ti(C,N) powders were used as raw materials, and the fabrication method was powder metallurgy, and the relevant compositions and properties of the tools are shown in Table 1 Table 2 of .

Pour the raw material powder from Table 1 into a planetary high-energy ball mill. Add hard alloy balls with a diameter of Ф8 at a ball-to-material mass ratio of 6:1, then add anhydrous ethanol.

Wet grind for 30 hours. The slurry must also undergo vacuum drying for at least 10 hours. Subsequently, granulation is performed using a 6 wt% gasoline rubber solution, followed by sieving through a 200-mesh screen. Press into shape, place in a hot isostatic pressing sintering furnace, and sinter at 1430°C for one hour.

Translated with DeepL.com (free version)

Cutting experimental conditions: machine tool: CA6140; cutting conditions: dry cutting; work material: 45 steel, hardness HB190; tool installation angle: a = 11 ° ~ 15 °, Y = – 6 °, K = 45 °; cutting dosage: VC = 210 ~ 380m/min, f = 0.2 ~ O.5mm/r, ap = 0.2 mm ~ 0.6mm.

Analysis of experimental results

The first stage is the initial wear stage. During this phase, wear occurs rapidly. This is mainly because the surface structure of the tool is not yet wear-resistant, or the tool surface is relatively rough.

The second stage is the steady-state wear stage. At this point, the non-wear-resistant surface layer has already been removed. The tool surface is subjected to reduced pressure and the force is more evenly distributed. As a result, the wear rate slows down.

This stage typically appears as a tilted straight line on a wear-time graph. Since the tool is in its effective working period during this stage, prolonged cutting time can still result in significant wear.

The third stage is the accelerated wear stage. At this point, the tool temperature rises rapidly and friction increases significantly. This leads to intense wear, causing a sharp decline in the cutting performance of the tool and eventually resulting in tool failure.

Effect of cutting speed on tool life

The cutting speed is not more than 200m/min, the cutting performance of both tools is better, but when the cutting speed is increased, the performance of both tools decreases significantly.

Further study found that at lower cutting speeds, tool A has a longer service life of , while at higher cutting speeds, tool B has a longer service life of than tool A.

This may be due to the fact that at low speeds, the wear and diffusion of the tool’s oxygen is relatively light, so tool A can maintain a longer life of .

When the cutting speed continues to increase, wear and diffusion will continue to exacerbate, tool B in the cubic boron nitride content is higher than the tool A, and the cubic boron nitride has a high resistance to oxidation and wear performance, so it greatly increases the service life of the tool B .

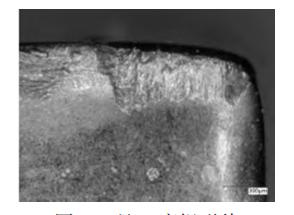

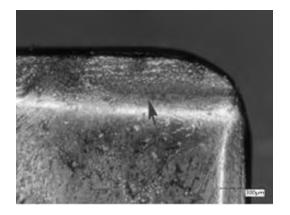

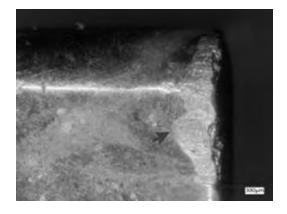

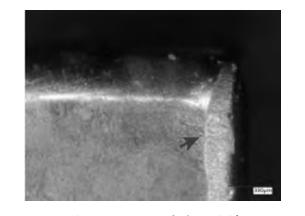

From Figures 1 and 2, it can be seen that at low cutting speeds, both tool A and tool B fail by normal wear, with the tip, face and boundary all showing wear, with the tip and boundary showing more severe wear, and the boundary showing the greatest amount of wear, which in some cases can be two to three times that of the face.

As the cutting speed at increases further, the failure mode of tool A changes to boundary wear at and tool B breaks down as a result of wear to a certain extent.

Influence of feed on tool life

The experiment shows that, with the increase of feed volume, in general, tool B has a longer service life than tool

A. When the feed volume f=0.1mm/r, the wear resistance of the tool is relatively strong, when the feed volume f=0.2mm/r, the two kinds of tools are violently worn out, and when the feed volume f=0.3mm/r, the service life of tool A is 2.6min, and the service life of tool B is 3.7min.

Further research at shows that the feed rate is directly related to the tool life.

The larger the feed, the greater the time and workload of the tool movement, the heat generated in the process also increases, raising the cutting temperature.

At the same time, an increase in the feed increases the cutting forces at and the friction between the tool and the workpiece increases, resulting in bond wear, edge chipping, and hard phase flaking, leading to eventual failure of the tool at .

The morphology of the wear area at feed f=0.2mm/r for both tools is shown in Fig. 3 and Fig. 4.

Cubic boron nitride composite Ti(C,N)-based metal-ceramic tools Wear mechanism of cutting performance

Metal-ceramic tools have special physical, chemical and mechanical properties.

Their wear characteristics are different from those of ordinary cemented carbide, and under dry cutting conditions, have the following characteristics.

Mechanical wear

The matrix structure of the workpiece material contains impurities, as well as hard particles such as carbides, tungsten oxides, and nitrides.

When these hard points come into contact with the tool during cutting, they cause mechanical abrasion on the tool surface. This abrasion leads to the formation of grooves and surface damage.

Such mechanical wear occurs at all cutting speeds, but it is especially significant at lower cutting speeds.

At low speeds, this type of mechanical abrasion becomes a dominant factor contributing to tool wear.

The study shows that the cutting distance and the amount of material worn away by grinding are positively proportional.

Since metal-ceramic tools can maintain very high cutting speeds, mechanical wear is not the primary form of wear during cutting.

Instead, the high cutting speed causes a significant increase in cutting temperature, which has a major impact on the tool’s performance and wear characteristics .

At high temperatures, the material of the tool itself will be changed due to wear, and the corresponding performance of the tool will also be changed, so the amount of wear caused by mechanical wear in high-speed cutting is also very influential.

Bonded Wear and Friction Welding

When the temperature and pressure reach certain conditions during cutting, a bonding phenomenon can occur at the contact surface between the tool and the workpiece. At this point, the atoms at the interface come close enough—reaching inter-atomic distances—to allow bonding.

Due to plastic deformation and frictional heat, a friction welding effect takes place between the tool and the workpiece materials. As a result, bonding points form at the contact surface.

During relative motion, these bonded areas are subjected to shear or tensile stress. This stress causes grains or grain clusters from one material to be pulled away and transferred to the other surface.

This mechanism leads to a specific type of tool wear known as adhesive wear (or bonding wear).

Bonding generally occurs on contact surfaces, and there is a certain incidence in both hard and soft materials .

The risk of rupture at the bonding point is relatively high when machining workpieces made of low-hardness materials.

However, in practice, bonding ruptures also occasionally occur on the tool surface itself.

This is mainly due to the uneven internal structure of the tool material, which includes factors such as internal stresses, localized soft spots, voids, and microcracks.

These imperfections can weaken the tool surface, making it susceptible to rupture during cutting.

Diffusive and oxidative wear

When the turning speed ranges between 200 m/min and 500 m/min, the cutting process enters a high-speed state, which generates a large amount of heat.

As a result, the temperature at the contact point between the tool and the workpiece rises rapidly, reaching approximately 1000 °C.

Although cermet tools possess strong chemical stability, heat resistance, and oxidation resistance, such extremely high temperatures still lead to significant tool wear.

At around 1000 °C, oxidative wear and diffusive wear become prominent, both of which directly accelerate the degradation and wear of the cutting tool.

On the one hand, the tool in the bonding phase Co, Ni to the workpiece diffusion intensified, the tool by

in the bonding phase is reduced, brittle; on the other hand, by the high temperature and wear difference , the machining of Fe will intensify the diffusion of the tool, and in the tool formation of low hardness brittle phase.

Both of these processes lead to a decrease in the cutting performance of the tool and an increase in tool wear.

Oxidative Wear and Grooving at High Temperatures

In the high temperature environment of cutting, the bonding point in the ceramic tool and the oxygen in the environment appear to react and produce oxides, the hardness of the oxides is relatively low , which will be taken away with the cutting action in the process of cutting, resulting in the oxygen wear, which is the main cause of the wear of the grooves.

The longer the cutting time, the more serious groove wear, sometimes leading to direct failure of the tool.

Diffusion Effects and Elemental Changes During Cutting

The original composition of the tool shows a normal content of cubic boron nitride (CBN), while the contents of Mo (molybdenum), Co (cobalt), and Ni (nickel) are very low.

However, after cutting under high temperature and high pressure, the contents of Fe (iron) and O (oxygen) on the tool surface increase significantly. This indicates that a diffusion reaction has occurred between the tool and the workpiece material.

As the cutting process continues, elements from the surface layer of the tool diffuse into the workpiece. At the same time, elements from the workpiece, especially Fe, diffuse into the tool.

This mutual diffusion alters the tool’s surface composition and contributes to its wear and degradation

Because of high temperature oxidation to form volatile substances and loss, part of the elements due to for the diffusion of the workpiece material and decomposition, cubic boron nitride (CBN) because of the excellent heat resistance and high hardness is still retained in the cutting tool material, become a stabilizing factor for cutting .

Comparative Performance of Tool A and Tool B

The cubic boron nitride (CBN) content of tool B is larger than that of tool A. In general, the cutting performance of tool B is higher than that of tool A.

However, through the cutting experiments, it is found that the cutting performance of tool A is better than that of tool B in low-speed cutting, and that the cutting performance of tool B is better than that of tool A in high speed cutting.

> Influence of Material Composition on Low-Speed Cutting

The reason for this is that during low-speed cutting, the cutting movement is not intense, which results in relatively mild diffusion and oxidative wear.

This behavior contrasts significantly with that seen in high-speed cutting.

Tool A, which contains a higher content of WC (tungsten carbide) and Co (cobalt), exhibits better toughness and bending strength. As a result, it delivers superior overall performance compared to Tool B under low-speed conditions.

Compared with the high-speed cutting, there is a significant difference between the tool A in the high content of WC and Co, has a better toughness and bending strength, shows the overall performance is higher than the tool B .

> Wear Mechanisms at High Cutting Speeds

However, as the cutting speed increases, the cutting temperature and heat generation also rise significantly. This leads to a marked increase in wear intensity.

At elevated temperatures, elements within the tool begin to diffuse into the workpiece or chip, resulting in the formation of a large number of microscopic voids within the tool material.

These tiny voids act as channels that allow oxygen from the air to penetrate deeper into the tool.

Once inside, oxygen reacts with the tool’s binder materials, triggering oxidation reactions that produce gaseous substances. This reaction further accelerates the loss of the original components of the tool.

As a result, the structural integrity of the tool declines, leading to significant material loss and, eventually, tool failure.

At the same time, a large amount of Fe from the workpiece diffuses into the tool, forming a new brittle substance.

Tool B, due to the higher content of cubic boron nitride (CBN), will not be easily diffused and lost, at high temperatures and high pressures, but still excellent stability and cutting performance, than the overall performance of tool A.

> Tool Design Limitations and Potential Optimization

Since the tested tool was not equipped with a chipbreaker and the geometry was not optimized, the chip wear on the front face of the tool was severe during the experiments.

At the same time, the surface roughness of the tool was large and not carefully ground, and there were some organizational defects on that limited the optimal performance of the tool.

If these unfavorable factors are excluded and the experimental results are combined, the cutting performance of the cermet tool is excellent.

Conclusion

(1) The addition of cubic boron nitride (CBN) can significantly improve the cutting performance of Ti(C,N)-funded metal ceramic tools, and the overall performance is good at higher cutting speeds.

(2) Cutting speed and the amount of feed on the tool wear has a greater impact, low speed cutting, cubic boron nitride (CBN) content of low tool wear is small, high-speed cutting on the contrary; the same amount of feed, tool wear and cubic boron nitride (CBN) content of inversely proportional to the relationship.

(3) Ti(C,N)-based metal-ceramic tools in high-speed cutting, the wear of the main forms of diffusion wear and oxidative wear, but mechanical wear and adhesive junction wear also have an important effect.