David Chuang

Current Research Status of Ultrasonic Cutting Processing for Aerospace Metallic Materials

China CNC Milling » Blog » Current Research Status of Ultrasonic Cutting Processing for Aerospace Metallic Materials

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Titanium alloys, high-temperature alloys, and other difficult-to-machine metallic materials are crucial raw materials.

They are used for manufacturing key aerospace engine components such as turbine disks, blades, and casings.

However, with rapid industrial advancement—particularly in aerospace—these critical components often operate under harsh conditions.

These conditions include high temperatures, high pressures, alternating cyclic loads, and humidity.

Consequently, industries place stringent and increasingly demanding requirements on their service performance.

How to extend the service life of critical components and achieve high-quality, efficient machining of metals like titanium alloys is a pressing research priority.

Part manufacturing precision is a crucial guarantee for service life.

Employing effective machining methods is a fundamental prerequisite for enhancing the service life of critical components.

As a common machining method, cutting holds a pivotal position in mechanical processing.

Industries thus widely apply it in machining difficult-to-machine metals.

However, the superior mechanical properties of these materials often result in high cutting forces and elevated cutting temperatures.

They can also cause severe tool wear and poor surface integrity during conventional machining.

This leads to low processing efficiency, reduced precision, and increased manufacturing costs.

Ultrasonic Vibration-Assisted Machining (UVAM) represents a non-traditional processing method.

It utilizes transducers, such as piezoelectric ceramics or magnetostrictive materials, to convert high-frequency electrical energy into high-frequency mechanical vibration energy.

This energy is then applied to the machining process to achieve ultra-precision material processing.

Compared to conventional methods, the fundamental change in machining characteristics leads to a transformative shift in material removal mechanisms.

Ultrasonic-assisted machining introduces ultrasonic vibrations between the workpiece and tool during cutting operations.

This significantly reduces friction between the tool and workpiece, thereby decreasing cutting forces and heat generation.

Simultaneously, ultrasonic vibrations at the cutting edge accelerate fatigue failure of chips, enhancing chip breaking efficiency.

Notably, the ultrasonic vibration acceleration of the tool can reach tens of thousands of times the gravitational acceleration.

The resulting inertial forces make chip adhesion to the cutting edge extremely difficult, preventing built-up edge formation and adhesive wear.

This confers unique advantages for machining aerospace metal materials.

Figure 1 illustrates how various factors influence cutting performance in ultrasonic machining.

Currently, industries apply ultrasonic vibration-assisted machining to difficult-to-machine metallic materials, achieving favorable processing results.

Current Research Status of Single Ultrasonic Cutting

Cutting Force

In traditional metal cutting processes, severe interactions occur between the cutting tool and the workpiece.

These interactions result in substantial cutting forces that pose significant challenges to process stability.

Consequently, some researchers have adopted ultrasonic cutting to reduce cutting forces and enhance process stability.

Cutting forces significantly impact tool wear and surface quality.

SHEN et al. investigated the variation patterns of milling forces during ultrasonic vibration-assisted vertical milling.

Results indicate that separation phenomena induced by ultrasonic vibration cause pulsating fluctuations in the cutting force curve.

This curve remains lower than the average cutting force in conventional milling.

SOFUOĞLU et al. employed DEFORM-2D finite element software to establish finite element models for titanium alloy and Hastelloy.

They analyzed these materials during conventional turning, ultrasonic vibration-assisted turning, and thermal ultrasonic vibration-assisted turning.

Analysis of cutting forces across these processes revealed that thermal ultrasonic vibration-assisted cutting exhibited the lowest cutting forces.

It also showed the lowest effective stresses.

For Hastelloy, thermal ultrasonic vibration-assisted turning reduced cutting forces by over 50%.

For titanium alloy, cutting forces decreased by approximately 70%.

This reduction stems from the thermal softening effect of ultrasonic vibration-assisted machining, which lowers cutting forces during processing.

Additionally, the intermittent separation between tool and workpiece during ultrasonic machining further diminishes cutting forces.

To suppress chatter during titanium alloy machining and enhance process stability, LANOS et al. employed ultrasonic vibration-assisted turning.

Targeting material removal rate, they established a cutting force model based on process parameters.

They also analyzed the influence of different machining conditions on cutting forces.

Results indicate that under identical parameters, ultrasonic vibration-assisted turning achieves lower cutting forces, thereby suppressing chatter during machining.

Based on ultrasonic milling tool trajectories, NIU et al. developed a maximum undeformed cutting thickness model.

This model was for longitudinal-torsional ultrasonic vibration-assisted milling.

Building upon the oblique cutting model and the cutting force geometric relationship model, they derived a milling force model.

This model applies under longitudinal-torsional ultrasonic vibration conditions.

They analyzed the influence patterns of tool geometric parameters and ultrasonic processing parameters on cutting forces.

Results indicate that predicted values align with experimental parameter variations.

Among ultrasonic processing parameters, longitudinal phase difference exerts the strongest influence on cutting forces in both directions.

This is followed by ultrasonic frequency and longitudinal vibration amplitude, while torsional amplitude has the least impact.

WANG et al. established a milling force prediction model under ultrasonic conditions based on tool geometry and cutting edge motion trajectories.

They also obtained the instantaneous cutting thickness of the cutting edge.

Results indicate that longitudinal-torsional ultrasonic vibration reduces radial cutting force.

Tangential and axial forces remain largely unchanged, primarily due to the vibration direction of the ultrasonic waves.

To enhance surface finish quality, XU et al. analyzed the mechanism of cutting force generation under ultrasonic conditions.

They also established a cutting force model for ultrasonic vibration-assisted turning of 304 stainless steel based on process parameters.

Results indicate that the separation effect induced by ultrasonic vibration can significantly reduce cutting forces during machining.

However, increasing amplitude does not yield better results; instead, an optimal value exists.

Appropriate matching of process parameters can improve machining performance.

NAMLU et al. investigated the influence of various process parameters on cutting forces during titanium alloy milling.

They combined ultrasonic vibration-assisted milling with minimal lubrication in their study.

Regardless of the cooling method, cutting forces under ultrasonic conditions consistently remained lower than those in conventional milling.

Simultaneously, researchers discovered that cutting force correlates with the machining stage, exhibiting distinct effects during roughing and finishing operations.

Ultrasonic cutting effectively reduces cutting force during roughing, while conventional cutting yields relatively lower forces during finishing.

Thus, the ideal combination for minimal cutting force involves Micro-Quantity Lubrication (MQL) with conventional milling (CM) for finishing.

For roughing, it involves MQL with Ultrasonic-Assisted Milling (UAM).

CHEN et al. analyzed the impact of ultrasonic vibration on the machining process through a fully transient cutting process.

Considering the effects of ultrasonic vibration on the shear angle and flow stress in the shear zone, they proposed a new model.

This model determines the average cutting force and transient cutting force.

Results indicate that multiple characteristics influence ultrasonic cutting processes.

These include transient behavior, acoustic softening, thermal softening, plowing, and friction.

Experimental cutting force values for Ti6Al4V, AISI 1045, and Al6063 materials exhibited prediction errors of approximately 7%, 10.2%, and 11%, respectively.

This demonstrates ultrasonic vibration’s effectiveness in reducing cutting forces.

Considering vibration’s impact on workpiece material cutting performance, NIK et al. first optimized the ultrasonic vibration device design.

They achieved this by integrating theoretical design, finite element simulation, and genetic algorithms.

Building on this, they analyzed how varying machining parameters affect cutting force and surface roughness.

They found that applying ultrasonic vibration reduces cutting force and improves surface quality.

Compared to conventional grinding, normal and tangential grinding forces under ultrasonic conditions decreased by 13.5% and 14.2%, respectively.

Wang Chenxu et al. investigated the removal mechanism of ultrasonic vibration-assisted grinding on GH4169 high-temperature alloy.

They also analyzed the influence of processing parameters on cutting performance.

Results demonstrated that ultrasonic vibration significantly reduced cutting forces and grinding wheel wear during machining.

It also markedly improved surface quality.

Cutting Temperature

In traditional metal cutting processes, the cutting contact zone generates extremely high temperatures.

These temperatures adversely affect tool life and surface finish quality.

Excessive cutting temperatures not only drastically reduce tool life but also cause adhesion and even delamination on the machined surface.

Therefore, ultrasonic cutting can effectively control cutting temperatures in titanium alloys.

This helps extend grinding wheel life and improve surface finish quality.

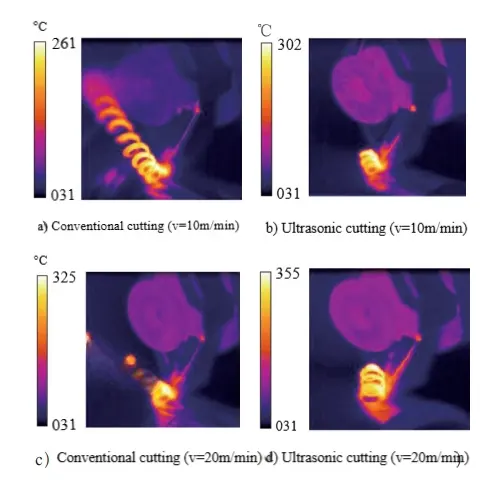

A comparison of cutting temperatures under different machining methods is shown in Figure 2.

To investigate the effect of ultrasonic vibration on turning processes, KHAJEHZADEH et al. employed Al₂O₃-coated tools.

These tools were used for ultrasonic-assisted turning of aerospace aluminum alloys.

They examined how ultrasonic amplitude, cutting speed, and feed rate influenced cutting temperature.

Results indicated that cooling efficiency depended on optimal process parameter selection.

Increasing ultrasonic amplitude at low feed rates effectively reduced cutting temperatures.

LOTFI et al. employed finite element simulation to analyze the effect of two-dimensional elliptical ultrasonic vibration.

They studied its impact on the machinability of nickel-based high-temperature alloys.

Findings revealed that applying elliptical vibration increases the shear angle.

It also reduces cutting temperatures on the rake face, thereby suppressing chip burr formation.

Based on a non-uniform moving heat source, CHEN et al. established a heat transfer model for ultrasonic-assisted machining of titanium alloys.

They analyzed the effects of ultrasonic amplitude and frequency on the machining heat transfer process.

Results indicated that the center of the equivalent heat source tended to shift backward on the tool’s rake face.

Temperature gradients in the horizontal and vertical directions were inconsistent.

Furthermore, researchers calculated the effects of varying vibration parameters on shear plane temperatures during flat and curved surface machining.

Increasing ultrasonic amplitude and frequency was found to reduce temperature gradients, thereby lowering shear plane temperatures.

Surface temperatures decreased with increasing ultrasonic amplitude but exhibited an upward trend with increasing frequency.

LIN et al. found that combining minimal lubrication with ultrasonic vibration further improves machining performance compared to ultrasonic vibration-assisted turning alone.

This combination significantly reduces cutting forces and temperatures.

The effectiveness of minimal lubrication depends on the nozzle angle.

Finite element simulations analyzed how different angles affect cutting temperature and stress variations.

The results indicate that an optimal nozzle angle facilitates proper cooling and lubrication, enhances surface finish quality, and extends tool life.

Considering the impact of high-frequency sinusoidal tip motion trajectories on the machining process, GHOLAMZADEH et al. conducted two-dimensional finite element simulations.

They studied ultrasonic vibration-assisted cutting under dry conditions.

They analyzed the influence of machining-related parameters on tip cutting temperatures.

Results indicated that under certain conditions, the instantaneous tip temperature was high.

However, the average temperature was relatively low, with the maximum temperature occurring slightly above the tip position.

To investigate the impact of the plowing effect on the machining process during ultrasonic vibration-assisted cutting of titanium alloys, CHEN et al. employed finite element simulation.

They analyzed the influence of tool tip radius on stress distribution within the plowing zone.

The results revealed that compared to conventional grinding, ultrasonic vibration reduces cutting temperatures during machining.

However, cutting temperatures still increase with rising cutting speeds and tool tip radius, peaking on the rake face.

This occurs because higher cutting speeds and larger tool tip radii increase cutting energy consumption.

As a result, tool heat accumulates continuously on the rake face through the chip, thereby elevating cutting temperatures.

Addressing the limitations of critical cutting speed on ultrasonic machining performance, ZHANG et al. proposed a high-speed vibration cutting method.

This method aims to enhance surface quality and machining efficiency.

They established a transient cutting temperature model to describe temperature variations within the cutting interface.

Results indicated that cutting speed and duty cycle are primary factors influencing cutting temperature, typically related to machining parameter settings.

To predict the impact of machining parameters on titanium alloy cutting performance, MUHAMMAD et al. employed a fuzzy logic model.

They used it to forecast the influence of process parameters on cutting temperature during ultrasonic vibration-assisted turning and conventional turning.

The established model demonstrated high prediction accuracy, revealing the underlying mechanism of temperature reduction in ultrasonic vibration cutting.

Tool Wear

Difficult-to-machine metals such as titanium alloys generate significant force and thermal loads during conventional cutting processes, leading to rapid tool wear.

Excessive tool wear not only shortens tool life but also significantly impacts machining quality, which in turn further exacerbates force and thermal load generation.

Figure 3 illustrates how different cutting methods affect tool wear.

Research indicates that ultrasonic vibration can effectively reduce tool wear.

Tool wear is a significant issue in titanium alloy machining.

NI et al. investigated the wear mechanism of tools under ultrasonic action.

They also analyzed the impact of different wear states on surface quality.

Results revealed that applying ultrasonic vibration in the feed direction primarily caused defects such as tip fracture and cracks in the tool.

These defects were mainly caused by high-frequency vibration impacts between the tool and workpiece.

However, wear levels were significantly reduced compared to conventional milling tools, while surface quality improved.

Additionally, researchers discovered that minimal cooling lubrication could further enhance machining outcomes.

To extend tool life during titanium alloy machining, Tong Jinglin et al. investigated the effect of longitudinal-torsional ultrasonic vibration.

They studied its impact on tool wear characteristics during milling.

Results indicated that longitudinal-torsional ultrasonic vibration altered the tool’s interaction with the workpiece.

This reduced rake face wear while simultaneously improving surface machining quality.

LIU et al. investigated the wear mechanisms of tools during ultrasonic vibration-assisted milling.

Their research revealed three forms of tool wear under ultrasonic vibration-assisted milling: oxidative wear, adhesive wear, and diffusion wear.

The tool achieved optimal surface finish quality during its normal wear stage.

Compared to conventional milling, ultrasonic vibration-assisted milling under identical conditions exhibits longer tool life and superior surface finish quality.

It also produces finer edge burrs and shows significant improvements in cutting force and temperature.

YU et al. investigated tool wear mechanisms during elliptical ultrasonic vibration-assisted turning.

They analyzed the intrinsic reasons for reduced wear under both separation and non-separation conditions.

Results indicate that in non-separation elliptical vibration cutting, the acoustic softening effect reduces material yield stress, thereby diminishing tool wear.

Conversely, under separation conditions, high-frequency tool-to-workpiece impacts lower contact stress, consequently reducing tool wear.

Surface Quality

Surface quality is a critical indicator affecting the fatigue life of workpieces, with its machining quality directly determining the service life of the component.

In recent years, to enhance surface integrity during machining of difficult-to-machine metals such as titanium alloys, numerous researchers have employed ultrasonic vibration-assisted cutting.

This approach has achieved excellent surface integrity.

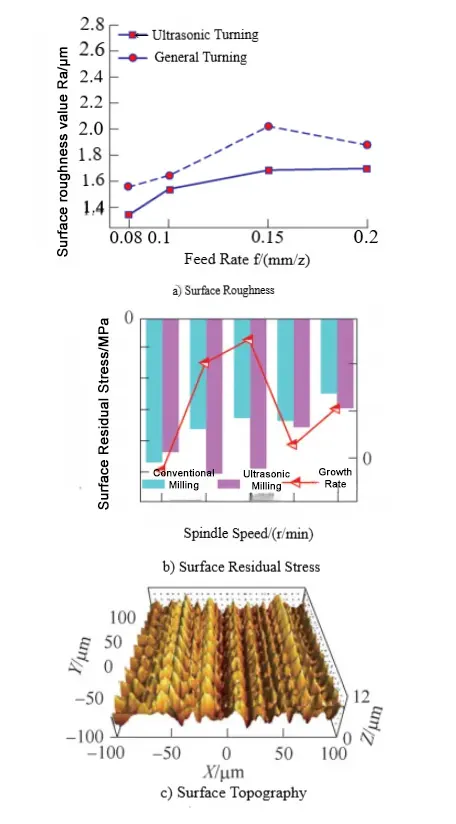

Figure 4 illustrates how ultrasonic vibration affects surface properties.

ZOU et al. conducted ultrasonic vibration-assisted turning on 304 austenitic stainless steel, analyzing the effect of ultrasonic vibration on machined surface roughness.

Results revealed that appropriate process parameter matching can reduce surface roughness values and improve surface machining quality.

SUI et al. investigated the formation mechanism of surfaces processed by ultrasonic high-speed turning.

Based on numerical simulation and finite element modeling, they established predictive models for surface morphology and roughness.

Results indicated that compared to conventional cutting, ultrasonic high-speed cutting achieves superior surface quality, with Ra values below 0.4 μm.

Considering the impact of machining parameters on TC18 surface integrity, XIE et al. employed ultrasonic vibration-assisted milling.

They analyzed the effects of rotational speed and ultrasonic amplitude on surface integrity.

Their results demonstrated that rotational speed significantly influences both surface morphology and residual stresses.

Compared to conventional milling surfaces, ultrasonic-treated surfaces exhibited more regular microstructures, with residual compressive stresses increasing by 50.9%.

Ultrasonic vibration also induced a plastic deformation layer on the machined surface, enhancing surface hardness and wear resistance.

The thickness of this plastic deformation layer increased with higher ultrasonic vibration levels.

To enhance the wear resistance of titanium alloy machined surfaces, PENG et al. employed high-speed ultrasonic vibration-assisted turning.

Characterization of surface integrity revealed that compared to conventional turning, ultrasonic vibration-assisted turning significantly reduced surface roughness values.

It also substantially increased the depth of surface plastic deformation.

This process generated a nanogradient layer of grains, thereby improving surface microhardness.

Furthermore, researchers observed residual compressive stresses as high as 840 MPa on the machined surfaces.

Current Research Status of Ultrasonic Composite Machining

Composite energy field-assisted machining is a method that builds upon single-energy-field-assisted machining.

It integrates additional energy fields for synergistic processing.

It leverages the distinct advantages of different energy fields to overcome the limitations of single-field-assisted machining.

This enhances process stability and improves both machining efficiency and quality.

Ultrasonic Laser Processing

DESWAL et al. developed a novel ultrasonic composite laser-assisted cutting process integrating ultrasonic vibration with laser technology.

Through machining of 3003 aluminum alloy, they conducted comparative analyses of the effects on material processing performance.

They compared conventional cutting, single ultrasonic vibration-assisted machining, and single laser processing.

Results revealed that compared to other methods, the ultrasonic-laser composite-assisted cutting process exhibited lower surface roughness values.

It also reduced cutting forces and produced smoother chips.

This is attributed to the composite process incorporating both the tool-workpiece contact-separation phenomenon characteristic of ultrasonic machining and the thermal softening effect of laser processing.

As a result, it produces lower cutting forces and smoother chip formation.

However, the ultrasonic-laser hybrid process exhibited the highest cutting temperature during machining.

This was attributed to the laser’s thermal effect, which further concentrated heat energy onto the machining zone during tool-workpiece separation.

This resulted in peak temperatures during cutting.

Considering the impact of ultrasonic-laser hybrid energy field processing conditions on the milling performance of titanium alloys, Su Yongsheng et al. analyzed the effects of this hybrid energy field on surface morphology.

They also studied its impact on cutting force, tool wear, and other performance metrics.

Results indicate that during conventional milling of laser-selectively melted titanium alloys, cutting force decreases with increasing cutting speed.

However, it increases with higher feed rates, while the surface exhibits pronounced tool marks.

In contrast, ultrasonic machining of laser-selectively melted titanium alloys exhibited relatively lower cutting forces and smoother machined surfaces.

This discrepancy stems from the combined effects of laser-induced changes in the metallographic structure of titanium alloys.

The tool-workpiece contact-separation characteristics inherent to ultrasonic machining also influence it.

Furthermore, within the selected parameter range, both conventional machining and ultrasonic machining of laser-sintered titanium alloys exhibited severe adhesion on the rake and flank faces of the tool.

This indicates the limited effectiveness of ultrasonic processing in enhancing anti-adhesion properties on these surfaces.

Optimal process parameters significantly influence machining outcomes.

DOMINGUEZ et al. investigated the effects of cutting parameters on cutting force and surface roughness.

They focused on laser-ultrasonic hybrid machining.

The results showed that both laser-only and ultrasonic-only machining reduced cutting forces and temperatures compared to conventional machining.

However, lower cutting parameters primarily constrained them.

In contrast, ultrasonic-laser hybrid machining combines the dual advantages of ultrasonic tool-workpiece separation characteristics and laser thermal softening effects.

This expands the range of usable cutting parameters.

This approach can further reduce cutting forces and surface roughness values while simultaneously improving machining efficiency.

Ultrasonic Magnetic Field Processing

YIP et al. also combined ultrasonic energy fields with magnetic fields to process titanium alloys.

By introducing a magnetic field into ultrasonic-assisted diamond cutting, the magnetic field compensated for the shortcomings of ultrasonic machining.

This minimized surface damage and side burrs caused by tool vibration, thereby improving the surface quality of titanium alloy machining.

Test results indicate that in the presence of a magnetic field, the degree of material swelling induced by the enhanced motion of ultrasonic tools is significantly reduced.

It is effectively suppressed.

The magnetic field minimizes the cutting scar area caused by the cyclic motion of ultrasonic tools.

Furthermore, the magnetic field significantly reduces the percentage errors in groove depth and width to 1.69% and 1.77%, respectively.

Figure 5 illustrates the effects of different machining methods on surface profile.

Ultrasonic Electrical Discharge Machining

DONG et al. established a material removal model for TC4 titanium alloy under single-pulse vertical ultrasonic vibration UEDM conditions.

The model is based on voltage variations during ultrasonic electrical discharge machining (UEDM) and heat transfer theory.

They analyzed the impact of different amplitudes on the material removal process.

Their results demonstrated that ultrasonic electrical discharge machining can achieve higher material removal rates and improved surface quality.

KURNIAWAN et al. performed ultrasonic-assisted turning on titanium alloys.

They employed finite element simulation to analyze the effects of various factors on the machining process.

Results indicated that electrical discharge softens the workpiece material, enhancing material removal rates.

Ultrasonic vibration reduces cutting forces and tool wear while also suppressing burr formation.

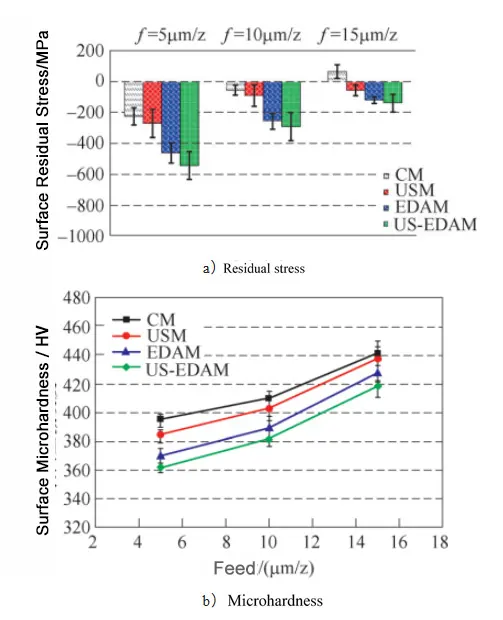

XU et al. applied this method to titanium alloys, comparing and analyzing electrical discharge machining (EDM), ultrasonic vibration-assisted milling.

The results indicate that ultrasonic-electro-discharge milling combines the dual advantages of ultrasonic vibration and EDM.

EDM softens the workpiece surface to reduce cutting forces, while ultrasonic vibration enhances EDM discharge efficiency and further diminishes cutting forces.

Compared to conventional milling (CM), ultrasonic-assisted machining (USM), and EDM-assisted machining (EDAM), UEDM delivers superior surface integrity and significantly suppresses edge burr formation.

Figure 6 illustrates how ultrasonic-electro-discharge machining impacts cutting performance.

Closing Remarks

This paper summarizes the current research status of ultrasonic machining for difficult-to-machine metallic materials and analyzes its impact on the machinability of such materials.

Studies indicate that ultrasonic machining offers advantages such as reduced cutting forces, lower cutting temperatures, extended tool life, and improved surface integrity.

However, several challenges and issues remain.

The following outlook addresses the current problems and challenges in ultrasonic machining of difficult-to-machine metallic materials.

Development of Dedicated High-Precision Vibration Cutting Machines

Developing specialized vibration cutting machines with high spindle rotational accuracy will fully leverage the precision cutting characteristics of vibration cutting.

This development is aimed at applications in micro-nano machining.

This will further enhance workpiece machining accuracy and surface quality, meeting the processing demands of high-precision components.

Advancing CNC and Intelligent Control in Ultrasonic Cutting

With the development of CNC technology, integrating ultrasonic cutting into CNC machines enables tools to achieve regular motion patterns, further improving machining accuracy.

Concurrently, combining artificial intelligence technology allows for intelligent control of ultrasonic cutting.

This optimizes cutting parameters to enhance processing efficiency and surface quality.

This will facilitate broader application of ultrasonic cutting technology across various fields.

Establishing and Refining Ultrasonic Cutting Standards

Industries must establish and refine relevant technical standards and specifications to promote widespread adoption and standardized development of ultrasonic cutting technology.

These standards will cover performance requirements for cutting equipment, tool selection, and usage methods.

They will also address the optimization of cutting parameters, providing robust support for the standardized and large-scale application of ultrasonic cutting technology.