David Chuang

Research on Complex Mold Processing Technology Based on Five Axis CNC Machine Tool

China CNC Milling » Blog » Research on Complex Mold Processing Technology Based on Five Axis CNC Machine Tool

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

The manufacturing industry is increasingly demanding high-precision, complex-shaped molds.

However, traditional CNC technology faces numerous challenges when processing these intricate molds.

Five-axis CNC machines are advanced machining equipment.

They leverage multi-degree-of-freedom motion capabilities and high-precision machining attributes to effectively address these issues.

Five-axis CNC machines enhance machining precision, reduce clamping frequency, and optimize production efficiency.

As a result, they significantly improve the quality and efficiency of complex mold machining, while also driving innovation in manufacturing.

Researching the application and key technologies of 5-axis CNC machines in complex mold machining holds significant theoretical importance.

At the same time, it provides practical approaches to elevate the technical sophistication and market competitiveness of the mold manufacturing industry.

Overview of 5-Axis CNC Machines

As a high-precision, high-efficiency machining device, 5-axis CNC machines enable simultaneous control across multiple directions.

Compared to traditional 3-axis machines, they offer superior machining capabilities and flexibility.

The primary feature of 5-axis CNC machines is their coordinated movement across five degrees of freedom.

This capability provides a broader machining space and greater freedom to efficiently process complex-shaped parts and molds.

Structurally, beyond the familiar X, Y, and Z axes, 5-axis CNC machines incorporate additional A and B axes.

These supplementary axes enable machining at multiple angles.

They reduce the frequency of clamping operations and minimize cumulative errors.

As a result, machining precision and stability are significantly enhanced.

With continuous technological evolution, the application scope of 5-axis CNC machines continues to expand.

They have become indispensable key equipment, particularly in fields such as aerospace, automotive manufacturing, and precision mold machining.

Advantages of 5-Axis CNC Machines in Complex Mold Processing

Enhanced Machining Precision and Efficiency

5-axis CNC machines offer significant advantages in machining precision and efficiency for complex mold fabrication.

By controlling five degrees of freedom, these machines can perform simultaneous machining operations across multiple angles and directions.

This enables the completion of complex geometric shapes in a single setup, eliminating cumulative errors caused by frequent re-clamping.

Achieving machining accuracy of ±0.005mm, they meet the stringent requirements for high-precision mold production.

Additionally, 5-axis machines optimize toolpaths to reduce mechanical movements, boosting machining efficiency.

This is particularly evident in large-scale complex mold production, where they markedly improve production efficiency and lower unit cost expenditures.

Enhanced Machining Freedom and Complex Shape Processing Capabilities

The core advantage of 5-axis CNC machine tools lies in their high machining flexibility.

Compared to 3-axis machines, 5-axis machines enable multi-axis control over the machining process, facilitating the production of complex geometries.

In aerospace and automotive industries, machining often involves complex surfaces, inclined planes, and deep holes.

Five-axis machines leverage their inherent flexibility to efficiently process areas that are difficult to access with conventional machines.

This flexibility makes 5-axis machines essential equipment for mold manufacturing and complex component machining.

They are capable of handling tasks beyond the reach of other CNC machines.

Their performance is particularly outstanding when faced with high-precision curved surface and three-dimensional structure machining requirements.

Optimizing Production Costs Through Reduced Fixtures and Setups

5-axis CNC machines enhance machining efficiency by minimizing frequent setups.

By utilizing 5-axis simultaneous motion, workpieces can undergo multi-surface machining in a single setup.

This reduces setup frequency and mitigates the impact of setup errors on machining accuracy.

Traditional 3-axis machines require multiple setups for complex machining.

In contrast, 5-axis machines can complete intricate mold processing in a single setup through flexible tool angle adjustments.

This not only enhances machining precision but also streamlines production workflows.

It simplifies equipment and operational complexity while lowering production costs.

Key Technologies of 5-Axis CNC Machines in Complex Mold Processing

5-Axis Interpolation Control Technology

As one of the core technologies of 5-axis CNC machines, 5-axis interpolation control enables simultaneous motion across five degrees of freedom.

Through precise motion regulation, it achieves higher machining accuracy and greater flexibility during processing.

This technology demands robust computational capabilities and efficient dynamic control from the CNC system.

These are necessary to ensure precise alignment between tool paths and workpiece positions.

Five-axis simultaneous control can execute complex curved surfaces and multi-angle machining tasks that are beyond the capabilities of conventional machines.

It also effectively reduces machining errors and enhances quality.

In practical applications, the control system’s maximum error is typically specified not to exceed 0.005 mm to meet mold precision requirements.

Toolpath Optimization and Trajectory Planning Technology

The machining efficiency and precision of 5-axis CNC machines primarily depend on toolpath optimization and trajectory planning.

The objective of toolpath optimization is to reduce non-cutting movement time and prevent unnecessary cutting idle runs, thereby shortening processing time.

Trajectory planning typically relies on factors such as cutting force distribution, tool geometry, and workpiece material.

Practical applications necessitate optimization calculations to prevent tool collisions or interference while ensuring smoother tool trajectories.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software facilitate toolpath optimization.

They automatically generate optimal paths to enhance machining efficiency.

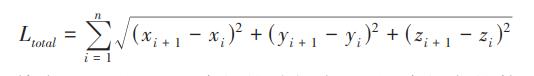

Computational-wise, tool path optimization commonly employs the following formula for shortest path planning:

Here, Ltotal represents the total length of the tool path, n denotes the number of path points, and (xi, yi, zi) and (xi+1, yi+1, zi+1) denote the coordinates of the path points at positions i and i+1, respectively.

By optimizing this path length, tool movement time and errors can be effectively reduced, thereby enhancing machining efficiency.

Tool Compensation and Collision Detection Technology

In 5-axis CNC machining, tool compensation technology plays a crucial role.

It is especially important during complex surface machining or multi-angle operations, where the tool’s actual position may deviate from the theoretical path.

Tool compensation technology corrects these deviations in real time, maintaining high machining precision.

Typically, compensation functions within the control system adjust the tool path to ensure the tool remains on the intended trajectory.

Complementary interference detection technology prevents collisions between the tool, workpiece, and fixture.

This helps avoid machine damage and machining errors.

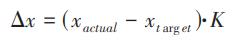

During tool compensation, the following formula is commonly used to calculate the compensation amount:

In this formula, Δx represents the tool position compensation value, where xactual and xtarget denote the tool’s actual position and target position respectively, and k is the tool compensation coefficient.

Utilizing this formula enables precise adjustment of the tool’s travel path.

This ensures the tool remains within the correct machining trajectory range, guaranteeing machining accuracy and quality.

The interference detection system employs computer-aided manufacturing software to simulate the machining process in real time.

It detects potential collisions between the tool path and the workpiece, ensuring the safety and reliability of the machining operation.

High-Speed High-Precision Interpolation Technology

To achieve efficient and high-precision machining on 5-axis CNC machines, high-speed, high-precision interpolation technology is indispensable.

High-speed interpolation enables faster, high-accuracy cutting, thereby reducing processing time and boosting production efficiency.

High-precision interpolation meticulously divides each machining step.

It optimizes the control system’s response speed to maintain high stability and machining accuracy, even during high-speed tool operation.

During actual operation, high-speed interpolation technology ensures the machine tool maintains rotational speeds of several thousand revolutions per minute.

At the same time, it achieves precision control, with typical errors not exceeding 0.001 mm.

This technology is particularly critical in complex mold machining.

It effectively reduces vibration during the machining process and improves surface quality and machining accuracy.

Optimization of Machining Processes for 5-Axis CNC Machines

Toolpath Optimization and Cutting Strategy Improvements

During machining operations on 5-axis CNC machines, optimizing tool paths and refining cutting strategies are critical.

Through rational tool path planning, unnecessary movement time can be reduced while effectively minimizing tool wear and extending tool life.

Optimized tool paths enable smoother machine operation, preventing vibrations and uneven cutting forces during complex surface machining .

Improving cutting strategies reduces thermal accumulation and stress concentration, lowering the probability of workpiece deformation.

Regarding cutting parameter selection, appropriate cutting depth and feed rates ensure process stability and precision.

In practical applications, tool path optimization can reduce machining time by 20% to 30%.

Following the implementation of optimized cutting strategies, the heat-affected zone during machining becomes smaller.

The distribution of cutting forces also becomes more uniform, thereby enhancing machining quality.

Fixture Design and Workpiece Stability Enhancement

In 5-axis CNC machining, the importance of fixture design cannot be overlooked.

Optimizing fixture design enhances workpiece stability and reduces vibration and errors during machining.

It also ensures efficient clamping of complex workpieces throughout multi-axis processing.

When machining with 5-axis CNC machines, fixtures should be selected and designed based on the workpiece geometry and machining requirements.

A well-designed fixture structure enhances clamping accuracy and stability.

It eliminates workpiece deformation or machining errors caused by improper fixture design.

Fixture design must also account for the machine’s working space to prevent excessive fixture volume from obstructing tool access to specific workpiece areas.

Precision fixture design typically maintains clamping accuracy within ±0.002mm, significantly improving machining precision and stability.

Optimization and Intelligent Adjustment of Machining Parameters

To enhance the machining quality and efficiency of 5-axis CNC machines, optimizing machining parameters is crucial.

By scientifically adjusting parameters such as cutting speed, feed rate, and cutting depth, the load on the machine tool and cutting tools can be reduced.

This helps minimize the impact of cutting forces during machining.

This minimizes heat generation during machining and lowers the extent of thermal deformation.

Consequently, it improves machining accuracy and surface finish.

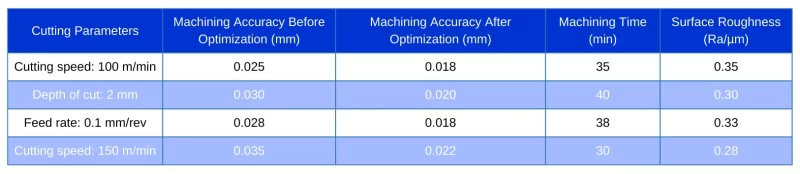

To visually demonstrate the impact of optimized and intelligent parameter adjustments on machining outcomes, Table 1 presents comparative data across different cutting parameters.

The data reveal that optimized cutting parameters significantly enhance machining accuracy while moderately reducing processing time.

For instance, setting the cutting speed to 100m/min machining accuracy improves from 0.025 mm to 0.018 mm, while surface roughness shows a decreasing trend.

Adjusting the feed rate and cutting depth similarly enhances precision and surface quality, reducing surface roughness Ra by approximately 0.02 µm.

Intelligent adjustment further boosts machining efficiency, minimizes operational errors, and ensures consistency and reliability in every processing cycle.

Such optimization significantly elevates the machine tool’s overall machining capability, boosting production efficiency while simultaneously reducing costs.

Conclusion

Following the adoption of 5-axis CNC machine tools, precision and efficiency in complex mold machining have seen significant improvements.

With the continuous advancement of smart manufacturing and artificial intelligence technologies, 5-axis CNC machines will achieve greater breakthroughs in adaptive control.

They will also see improvements in real-time error compensation and intelligent toolpath planning.

The integration of digital twin technology with big data analytics will enable more precise predictive maintenance for 5-axis CNC machines.

This approach reduces equipment failure rates and extends machine service life.

Future 5-axis machining will evolve toward greater intelligence, efficiency, and environmental sustainability.

This will provide a more competitive technological foundation for modern industrial manufacturing systems.