China CNC Milling » Blog » Application of Dynamic Milling on Machines with Legacy CNC Systems

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

High-speed dynamic milling has gained widespread adoption in rough machining applications due to its significant advantages: high efficiency, low machine tool load, minimal tool wear, and intelligent programming.

Research Background

The company’s production site currently operates five outdated CNC machining units with the following configurations:

– One VMC1000 vertical machining center and one VMC1200S vertical machining center, both purchased from Chengdu Top CNC Co., Ltd. in April 2005; Two PL800 vertical machining centers purchased in September 2006 from Chengdu Purui CNC Machine Tool Co., Ltd.

All four machines are equipped with FANUC Series Oi-MC CNC systems featuring only 256KB of memory; One PV750 CNC milling machine purchased from Chengdu Purui CNC Machine Tool Co., Ltd. in December 2008, utilizing the HNC Century Star system with a maximum spindle speed of 4500 r/min.

The VMC1200S vertical machining center employs a BT50 tool holder, while the remaining equipment uses BT40 universal tool holders.

These legacy machines primarily handle rough machining of components like housings and casings, processing materials ranging from aluminum alloys and high-temperature alloys to hardened 40Cr steel.

Due to prolonged service life and performance degradation, conventional layer milling methods result in significant issues: low machining efficiency, poor tool utilization, severe machine vibration, and elevated production costs.

To address these issues, enhance machining efficiency, and reduce production costs, the company plans to introduce dynamic milling technology on these older CNC machines.

Through practical machining research and application verification, four core challenges have been identified in implementing dynamic milling on legacy systems:

First, incompatibility between dynamic milling program code and outdated equipment systems;

second, insufficient stability of legacy equipment to meet dynamic machining requirements;

third, inadequate memory storage capacity within old systems; and fourth, the scientific determination of dynamic milling process parameters.

Solution

Addressing the Incompatibility of High-Speed Dynamic Milling on Legacy Equipment Systems

The company’s older FANUC system machines are factory-set to standard machining mode by default.

In this mode, the machine does not pre-read the machining program.

Dynamic milling generates program code composed of numerous minute linear segments. When such dynamic machining

G-code is fed into the machine, it often fails to quickly and accurately identify tool path points in densely populated areas (especially circular paths) due to insufficient program segment pre-reading capability.

This frequently leads to tool waiting, part overcutting, and tool collisions.

To address this issue, the following two solutions are adopted.

(1) Modify the post-processor by inserting pre-reading instructions into the program. Insert the

G05.1 Q1 command at the program header to enable program pre-reading, and insert G05.1 Q0 at the program tail to disable this function.

This resolves the issue of dynamic command codes running normally on older FANUC system equipment.

Note that this pair of commands must be used together, positioned at the program’s beginning and end respectively; otherwise, the machine tool will trigger an alarm.

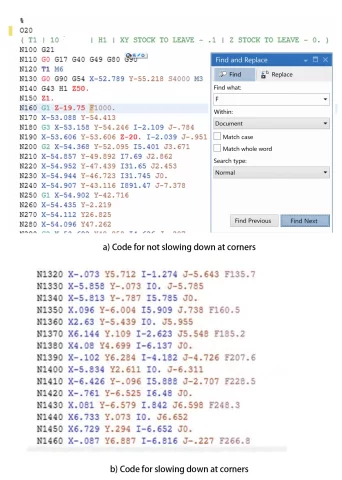

An example program containing pre-reading commands is shown below.

(2) Modify system parameter to enable machine tool pre-read command By setting system parameter 1604#0 to “1”, the machine tool defaults to high-speed, high-precision functionality upon startup.

The pre-read command is activated, enabling dynamic machining operations.

Enhancing Stability of Legacy Equipment to Meet Dynamic Machining Mode Requirements

Legacy equipment equipped with HNC systems fails to automatically decelerate during corner machining in dynamic mode.

This results in significant machine vibration, excessive noise, and a sharp increase in machine and tool load.

Not only does this heighten the risk of tool breakage and shorten equipment/tool life, but it also causes severe vibration marks on machined surfaces, leading to inconsistent part quality.

To address this issue, program corner speeds can be optimized through the following two methods:

(1) Software Optimization of Program Corner Speed

Utilize the corner deceleration setting function in the machining software during programming to enable variable-speed cutting at corners.

Taking a specific machining software as an example, the original post-processer only outputs a single feed rate, as shown in Figure 1a.

The program contains no speed change commands throughout.

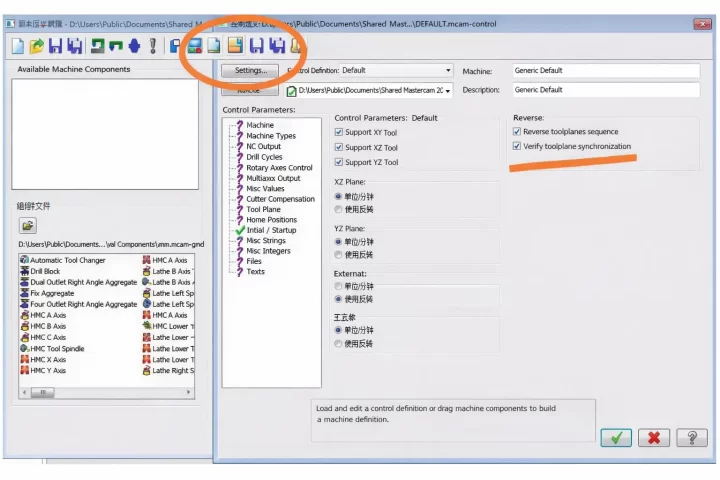

To enable the corner deceleration function, perform the following steps: Navigate to “Machine Definition → Control Definition → Feed Rate,” then check “Adjust Feed Rate for Arcs.”

The specific settings are illustrated in Figure 2. After configuration, the program automatically adjusts feed rates when entering arc cutting segments.

For instance, the feed rate changes when line N1320 enters G3 arc cutting, achieving corner deceleration (see Figure 1b).

Currently, most newer programming software versions offer similar configuration capabilities, allowing flexible adjustments based on actual production requirements.

(2) Code Optimization for Corner Speed

Directly edit the output program code by incorporating the G64 modal command.

This command effectively controls acceleration and deceleration processes across all machine tool axes, reducing mechanical vibration, protecting both the machine and workpiece, extending equipment lifespan, and simultaneously enhancing machining efficiency.

For example, modify the original program segment G0 G90 G54 X-1.239 Y-4.326 S4000 M3 to G0 G90 G54 G64 X-1.239 Y-4.326 S4000 M3.

Resolving the Issue of Insufficient Memory Storage in Legacy Equipment Systems

Legacy equipment equipped with FANUC control systems has a memory capacity of only 256KB.

Dynamic milling, characterized by large axial cuts and small radial cuts, generates programs with numerous segment lines that consume significant memory.

This results in most dynamic milling programs failing to load properly on older equipment.

To address this issue, optimize program memory through the following steps:

(1) Enable Arc Tolerance Filtering

Dynamic milling programs contain numerous minute line segments.

Activating arc tolerance filtering consolidates multiple small segments into arc code, simplifying the program.

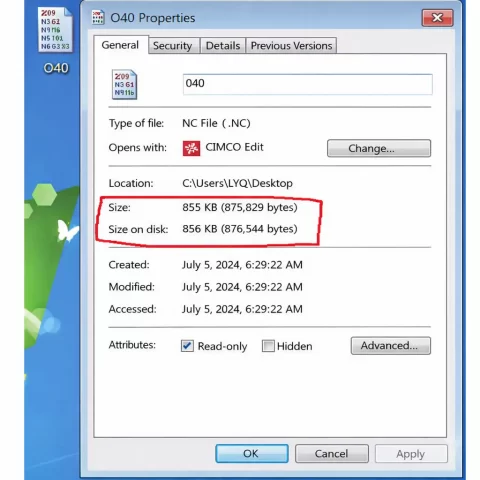

For example, when machining an internal cavity with a 10mm diameter tool: – Without arc filtering tolerance: 37,395 program lines, 856KB memory usage (see Figure 3) – With arc filtering tolerance enabled: Significantly reduced tool path points, program lines reduced to 2,693, memory usage reduced to 104KB.

The comparison of optimized and unoptimized program lines is shown in Figure 4.

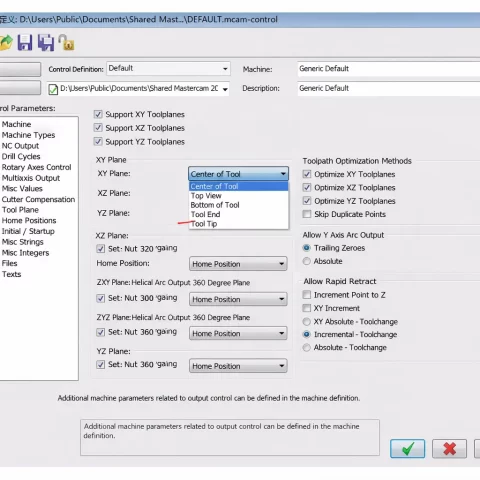

(2) Converting I, J, K Codes to R Codes

Further optimize the program within the machining software.

Under “Machine Definition → Control Definition → Arc Parameter Adjustment,” change the default “Start to Center Position” to “Radius” mode (see Figure 5). This converts I, J, and K codes to R codes within the program, reducing program memory to 88.4KB.

This fully meets the 256KB memory storage requirement of legacy equipment.

The above steps resolve the issue of excessive memory consumption in dynamic milling programs, preventing their execution on legacy systems.

The program optimization methods and machining software functions described herein are universally applicable.

Mainstream machining software on the market offers similar capabilities, allowing users to adjust software settings and program code according to actual machining requirements.

If memory constraints persist after implementing these optimizations, alternative solutions such as online machining or USB drive transfer can be employed.

Determining Dynamic Milling Parameters Scientifically

After a year and a half of practical verification, the company has processed a large number of parts made of various materials, including aluminum alloys and steel components, using dynamic milling on older CNC machine tools.

The following insights on tool usage and parameter selection have been summarized.

1) When machining internal cavities in high-hardness materials, prioritize the “drilling + spiral down-cutting” approach: First drill holes in the machining area, then use a milling cutter to spiral down from the hole position to the specified depth.

This prevents prolonged continuous cutting at the tool tip, effectively protecting it and extending tool life.

2) Dynamic milling enables reuse of tools discarded during finishing operations.

The dynamic cutting process is stable, with balanced tool forces and essentially constant cutting pressure.

It automatically optimizes paths around part corners, achieving “one tool for multiple uses.”

Practice shows each tool can process approximately 60 parts of identical specifications, significantly improving tool utilization.

3) Optimized machining parameters for different materials.

For aluminum alloy machining: Recommended parameters are 4000 rpm spindle speed, 1500 mm/min feed rate, and a side-tooth chip width of 5% of tool diameter.

Under these conditions, tool performance is optimal, with roughing efficiency increased by 90% compared to traditional methods.

For high-hardness materials (e.g.,40Cr after heat treatment, 45 steel): Recommended parameters are 3600 rpm, 1500 mm/min feed rate, and a side-cutting width of 2.5%–3% of the tool diameter.

These settings maximize tool performance, boosting roughing efficiency by 90% compared to conventional methods.

Conclusion

To achieve efficient dynamic milling applications on legacy CNC machine tools, this paper analyzes four critical dimensions: code recognition and adaptation for outdated systems, enhancement of machining stability, program memory optimization, and selection of cutting tools and machining parameters.

It specifically addresses core challenges encountered when implementing dynamic milling on older CNC systems.

After one and a half years of practical machining validation, the roughing efficiency of the company’s legacy system machines has significantly improved when processing parts made of various materials such as aluminum alloys and high-temperature alloys.

Concurrently, tooling costs have been effectively reduced, and equipment utilization rates have substantially increased.

Calculations indicate that after applying dynamic milling, CNC rough milling efficiency has increased by approximately 90%, tooling costs have been reduced by 20%, and equipment utilization has risen by 30%, generating substantial economic benefits for the enterprise.

-353x480.jpg)