China CNC Milling » Blog » Analysis of the Application of Metal Materials in Mechanical Manufacturing

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

With the advancement of technology, the mechanical manufacturing industry has become increasingly crucial to a nation’s industrial strength and competitiveness.

Metal materials, as the foundation of this industry, play a pivotal role in determining the quality of products.

In recent years, the emergence of new materials and processes has led to an increase in the variety and performance of metal materials.

However, selecting the appropriate materials remains a significant challenge.

Theoretically, conducting in-depth research into the fundamental properties, classification, and material selection principles of metal materials in mechanical manufacturing can enrich application theories and provide support for scientific research.

Practically, analyzing application cases in fields such as aerospace, automotive, construction machinery, and precision instruments can guide enterprises in material selection, thereby improving product quality, reducing costs, and enhancing competitiveness.

Basic properties of metallic materials

Physical properties

The physical properties of metallic materials are among the most fundamental and important characteristics.

Metals typically exhibit excellent electrical conductivity and thermal conductivity, making them widely used in the electrical and electronics industries.

For example, copper and aluminum are extensively utilized in the production of wires and cables due to their superior electrical conductivity.

Metals also possess high density and melting points, properties that are crucial for material processing and selecting suitable application environments.

The luster and ductility of metals are also unique physical properties that make them equally popular in decorative and artistic applications.

Mechanical properties

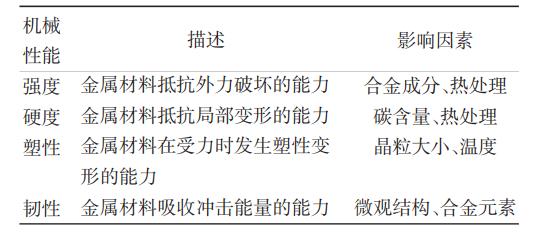

Mechanical properties are the most critical characteristics of metallic materials in mechanical manufacturing, including strength, hardness, plasticity, and toughness, as shown in Table 1.

Strength refers to the ability of a metal material to resist external forces that could cause damage.

It is an important indicator for ensuring the safe and reliable operation of mechanical parts and components.

Hardness reflects the ability of a metal material to resist local deformation, which is particularly important for parts that require wear resistance and scratch resistance.

Plasticity and toughness respectively indicate the ability of a metal material to undergo plastic deformation under stress and the ability to absorb impact energy.

These properties are of great significance for improving the processability and impact resistance of materials.

Chemical properties

The chemical properties of metallic materials determine their stability and corrosion resistance in specific environments.

For example, stainless steel is widely used in corrosive environments such as chemical engineering and marine applications due to its excellent corrosion resistance.

The chemical reactivity of metallic materials is another important aspect of their chemical properties, as it influences their reactivity with other substances and weldability.

Understanding and controlling the chemical properties of metallic materials is crucial for enhancing the service life and reliability of mechanical products.

Process performance

Processing performance refers to the characteristics exhibited by metallic materials during the manufacturing process, including castability, forgeability, weldability, and machinability.

Good processing performance enables metallic materials to be easily formed and processed during manufacturing, thereby improving production efficiency and reducing production costs.

Good process performance also ensures that the processed parts and components have accurate dimensions and shapes, as well as good surface quality.

Therefore, when selecting metal materials, their process performance must be fully considered to meet the requirements of mechanical manufacturing.

Classification of metal materials

Ferrous materials

Black metal materials primarily refer to iron, chromium, manganese, and their alloys, with iron-carbon alloys (i.e., steel) being the most common.

Steel materials dominate mechanical manufacturing due to their excellent mechanical properties, processability, and relatively low cost.

Steel materials can be further classified into two major categories: carbon steel and alloy steel.

Carbon steel primarily contains iron and carbon, and by adjusting the carbon content, different hardness and strength levels can be achieved.

Alloy steel, on the other hand, is produced by adding certain amounts of alloy elements such as chromium, nickel, and molybdenum to carbon steel, thereby enhancing its corrosion resistance, heat resistance, or strength properties.

Non-ferrous metal materials

Non-ferrous metals, as the name suggests, refer to all metal materials other than ferrous metals.

They typically exhibit excellent electrical conductivity, thermal conductivity, corrosion resistance, and specific mechanical properties.

Common non-ferrous metals include copper, aluminum, magnesium, and titanium.

Copper, with its outstanding electrical and thermal conductivity, is widely used in the electrical and electronics industries; aluminum, with its low density, high strength, and excellent corrosion resistance, is extensively applied in aerospace, aviation, and automotive manufacturing sectors; magnesium and titanium, with their unique physical and chemical properties, hold a distinctive position in high-end manufacturing fields.

Composite materials

Composite materials are new materials made by combining two or more materials through physical or chemical methods.

In metal materials, common composite materials include metal-based composite materials, which use metal as the base material and add reinforcing phases (such as ceramic particles, fibers, etc.) to improve their strength, hardness, or wear resistance.

Composite materials have comprehensive properties that cannot be matched by single materials, so they have broad application prospects in mechanical manufacturing.

New metal materials

With the advancement of technology, new types of metallic materials are constantly emerging, typically exhibiting unique physical, chemical, or mechanical properties, such as shape memory alloys, superconducting materials, and nanometallic materials.

These novel metallic materials hold immense application potential in high-tech fields such as aerospace, electronics, and biomedicine, representing a key direction for the future development of metallic materials.

Analysis of Commonly Used Metal Materials in Mechanical Manufacturing

Carbon steel

Carbon steel is a type of iron-carbon alloy, as shown in Figure 1, with iron and carbon as its main components.

The carbon content is generally low, not exceeding 2.14%. Based on carbon content, carbon steel can be classified into low-carbon steel, medium-carbon steel, and high-carbon steel. Low-carbon steel has good plasticity and weldability, and is commonly used for manufacturing structural components, stamped parts, and welded parts, etc.

Medium-carbon steel has higher strength and hardness, making it suitable for manufacturing mechanical parts and tools.

High-carbon steel, due to its high hardness and wear resistance, is commonly used for manufacturing tools, dies, and springs.

Carbon steel is widely used in mechanical manufacturing due to its low cost, good machinability, and moderate mechanical properties.

Alloy steel

Alloy steel is a type of steel produced by adding one or more alloying elements (such as chromium, nickel, molybdenum, titanium, etc.) to carbon steel.

The addition of alloying elements significantly enhances the steel’s strength, hardness, corrosion resistance, heat resistance, and wear resistance.

Depending on the type and amount of alloying elements added, alloy steel can be classified into low-alloy steel, medium-alloy steel, and high-alloy steel.

Low-alloy steel is primarily used for manufacturing large structural components such as bridges, buildings, and ships.

Medium-alloy steel is suitable for producing mechanical parts, bearings, and gears that significant loads.

High-alloy steel, due to its unique properties, is often used for manufacturing components in high-temperature, high-pressure, and corrosive environments.

Alloy steel, with its excellent comprehensive properties, plays a crucial role in mechanical manufacturing.

Cast iron

Cast iron is a type of iron-carbon alloy with a high carbon content, typically exceeding 2.14%.

It offers excellent castability, wear resistance, and vibration damping properties, and is relatively cost-effective.

Depending on its microstructure and properties, cast iron can be classified into gray cast iron, ductile iron, and malleable iron, among others.

Gray cast iron, due to its good castability and machinability, is commonly used to manufacture machine tool beds, cylinder heads, and pump bodies.

Ductile iron, with its higher strength and ductility, is suitable for manufacturing complex mechanical parts subjected to varying loads.

Malleable iron, with its good ductility and toughness, is often used to manufacture pipe fittings and automotive parts.

Cast iron is widely used in mechanical manufacturing due to its unique properties and application advantages.

Nonferrous metals

Non-ferrous metals refer to all metals and their alloys except iron, chromium, and manganese.

Non-ferrous metals have excellent electrical conductivity, thermal conductivity, corrosion resistance, and specific mechanical properties.

Commonly used non-ferrous metals in mechanical manufacturing include copper, aluminum, magnesium, and titanium.

Copper, due to its excellent electrical and thermal conductivity, is commonly used in the production of wires, cables, and heat sinks.

Aluminum, with its low density, high strength, and good corrosion resistance, is widely applied in aerospace, aviation, and automotive manufacturing.

Magnesium and titanium, with their unique physical and chemical properties, have distinctive applications in high-end manufacturing sectors.

Non-ferrous metals play a crucial role in mechanical manufacturing due to their unique properties and application advantages.

Principles for selecting metal materials in mechanical manufacturing

Performance requirements

Performance characteristics are the primary consideration when selecting metallic materials.

Mechanical manufacturing products are subjected to various loads and environmental conditions during use, so the selected metallic materials must possess sufficient strength, hardness, toughness, wear resistance, corrosion resistance, and high-temperature performance.

For example, for mechanical components subjected to heavy loads and impacts, alloy steels with high strength and toughness should be selected; for components operating in corrosive environments, stainless steel or titanium alloys with excellent corrosion resistance; for equipment operating in high-temperature environments, heat-resistant steel or nickel-based alloys with high thermal stability and oxidation resistance should be selected.

Processability considerations

Processability is another important consideration when selecting metal materials.

During mechanical manufacturing processes, metal materials undergo various processing techniques such as casting, forging, welding, and machining.

Therefore, the selected materials must possess excellent castability, forgeability, weldability, and machinability.

For example, for components that require casting, cast iron or cast steel with good fluidity and shrinkage properties should be selected; for parts that require forging, steel with good plasticity and deformation capability should be chosen; for structures that require welding, welding materials with good weldability and weld strength should be selected; and for parts that require machining, steel with good machinability and surface finish quality should be chosen.

Economic evaluation

Economic considerations are an important factor when selecting metal materials.

The cost of mechanical manufacturing products is directly affected by the price of the selected materials.

Therefore, when selecting metal materials, it is necessary to comprehensively consider factors such as material cost, processing costs, service life, and maintenance costs.

Under the premise of meeting usage performance and processing requirements, it is advisable to select metal materials that are reasonably priced, have low processing costs, a long service life, and are easy to maintain, in order to reduce product manufacturing costs and enhance market competitiveness.

Environmental and sustainability factors

As environmental awareness continues to grow, environmental and sustainability factors are becoming increasingly important in the selection of metal materials.

When selecting metal materials, it is essential to fully consider their environmental friendliness, recyclability, and resource utilization efficiency.

For example, priority should be given to non-toxic, harmless, and low-pollution green metal materials; for recyclable metal materials, their recyclability and reusability should be prioritized; and attention should also be paid to the resource utilization efficiency of metal materials, with a preference for those that are abundant in resources and have low extraction costs, thereby achieving the goals of sustainable development.

Specific applications of metal materials in mechanical manufacturing

Applications in the aerospace field

The aerospace industry imposes extremely stringent requirements on metallic materials, which must exhibit high strength, low density, excellent high-temperature resistance, corrosion resistance, and superior machinability.

Titanium alloys, with their low density, high strength, and excellent corrosion resistance, have found widespread application in the aerospace sector.

For example, the Boeing 787 Dreamliner extensively utilizes titanium alloy materials in its airframe structure, not only reducing aircraft weight and improving fuel efficiency but also enhancing the aircraft’s structural strength and corrosion resistance.

High-temperature alloys also play a critical role in aerospace engine manufacturing.

For instance, the turbine blades of a certain type of aircraft engine are made from nickel-based high-temperature alloys, which maintain high strength and excellent oxidation resistance at high temperatures, ensuring the engine’s stable operation.

Applications in the automotive manufacturing industry

The automotive manufacturing industry is one of the key application areas for metal materials.

With the growing trend toward lightweight and energy-efficient vehicles, new metal materials such as aluminum alloys, high-strength steel, and composite materials are being increasingly adopted in automotive manufacturing.

Taking aluminum alloys as an example, a well-known automotive brand has extensively utilized aluminum alloy materials in the body structure of its new electric vehicle model, effectively reducing the vehicle’s weight and enhancing its range and acceleration performance.

Applications in the manufacture of construction machinery and heavy equipment

Construction machinery and heavy equipment place extremely high demands on the strength, toughness, and wear resistance of metallic materials.

Traditional metallic materials such as carbon steel, alloy steel, and cast iron continue to dominate the market.

For example, components such as buckets and teeth plates in construction machinery like excavators and loaders are often made from high-manganese steel, which offers excellent wear resistance and impact toughness, enabling it to withstand severe wear and impact under harsh operating conditions.

In heavy equipment manufacturing, such as large presses and cranes, high-strength alloy steels are also widely used to ensure the equipment’s load-bearing capacity and operational stability.

A crane used in the construction of a large bridge was manufactured using high-strength alloy steels such as Q345, effectively enhancing the crane’s load-bearing capacity and safety.

Applications in the manufacture of precision instruments and electronic products

Precision instruments and electronic products have strict requirements for the precision, stability, conductivity, and corrosion resistance of metal materials.

In these fields, non-ferrous metals such as copper, aluminum, titanium, and their alloys are widely used. Taking electronic products as an example, copper is extensively used as a conductive material in the internal structures of devices such as smartphones and tablets.

Copper has excellent conductivity and processability, ensuring stable and reliable signal transmission in electronic devices.

Aluminum alloys also play a crucial role in the manufacturing of electronic product casings.

For instance, the casing of a certain high-end smartphone is made from aerospace-grade aluminum alloy, which not only reduces the phone’s weight but also enhances the casing’s strength and corrosion resistance.

In the manufacturing of precision instruments, such as optical instruments and medical devices, there are also special requirements for metal materials.

Conclusion

The article provides a systematic analysis of the application of metallic materials in mechanical manufacturing, covering their basic properties, classification, and detailed explanations of commonly used materials, as well as discussions on material selection principles, and analyses of their practical applications in fields such as aerospace, automotive, construction machinery, and precision instruments.

The study found that metallic materials, with their unique performance advantages, hold an irreplaceable position in mechanical manufacturing.

As science and technology and the manufacturing industry continue to develop, their applications will become even more widespread and in-depth. In the future, it is essential to strengthen research and development innovation, enhance performance and quality to meet industry demands, while also prioritizing environmental protection and sustainability to promote green manufacturing.

It is believed that the future prospects for metal materials in mechanical manufacturing are bright.