David Chuang

Advancements in Precision Machining: Key Technologies Driving Modern Mechanical Manufacturing

China CNC Milling » Blog » Advancements in Precision Machining: Key Technologies Driving Modern Mechanical Manufacturing

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

The advancement of mechanical manufacturing processes serves as the core driving force behind industrial modernization.

Through the convergence of materials science, information technology, and equipment technology, precision machining techniques have progressively overcome the limitations of traditional processes.

They demonstrate significant application value in fields such as aerospace, medical devices, and optical components.

This paper focuses on process innovation to explore the core methodologies of precision machining technology and its mechanisms for optimizing manufacturing workflows.

It thereby provides theoretical support for technological upgrades within the industry.

Key Technologies in Modern Mechanical Manufacturing Processes

Integrated Machining Technology

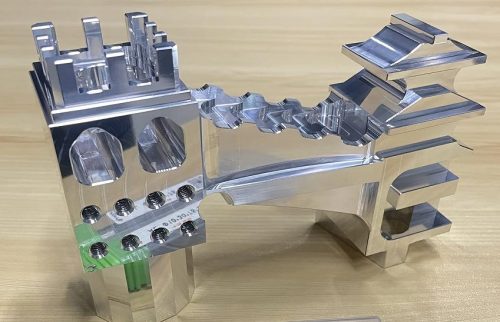

Integrated machining technology overcomes the limitations of traditional processes through multi-process integration strategies.

It combines heterogeneous machining methods such as turning, milling, and grinding on a single equipment platform.

This enables efficient forming capabilities for complex structural components.

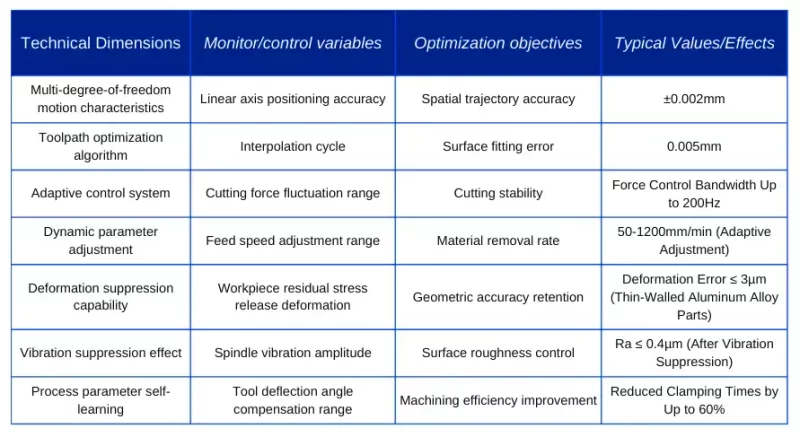

Taking a five-axis machining center as an example, it has multi-degree-of-freedom motion characteristics.

Combined with toolpath optimization algorithms, this enables continuous cutting for difficult-to-machine objects like thin-walled parts and irregular curved surfaces.

This approach avoids reference offset issues caused by multiple setups.

During machining, the adaptive control system dynamically adjusts feed rates and tool deflection angles by acquiring cutting forces, vibration signals, and workpiece deformation data in real time.

This helps suppress deformation errors caused by residual stress release in materials.

Composite machining data for five-axis machining centers is shown in Table 1.

Additionally, composite machining equipment autonomously matches tool materials, coolant parameters, and spindle speeds using its built-in process knowledge base and expert system.

This significantly reduces process debugging cycles.

This technology has achieved large-scale application in manufacturing precision components such as aerospace engine blades and medical device implants.

Its core advantages lie in reducing redundant process transitions and enhancing machining consistency.

At the same time, it lowers energy consumption and auxiliary material usage, thereby providing technical support for the mass production of complex products.

Micro-Nano Scale Manufacturing Technology

Micro-nano scale manufacturing technology leverages ultra-precision machine tools and ion beam processing systems to overcome the precision limitations of macro-scale manufacturing.

It enables controlled processing of sub-micron feature structures.

In semiconductor device fabrication, this technology employs the synergistic action of focused ion beam etching and chemical mechanical polishing.

It achieves directional formation of nanoscale trenches on wafer surfaces, ensuring uniformity in the thickness of insulating layers between integrated circuit transistors.

For MEMS sensors, precise control of surface roughness during micro/nanofabrication directly impacts stress distribution and signal output stability in piezoresistive elements.

Atomic layer deposition techniques are employed to modify silicon-based material interfaces, eliminating microcracks and lattice defects.

Air-bearing guides and laser interferometry systems in ultra-precision machine tools ensure stable tool movement under low-speed feed conditions.

This prevents edge chipping during brittle material processing.

Currently, micro-nano manufacturing technologies are evolving toward cross-scale integration.

For instance, femtosecond laser two-photon polymerization enables the three-dimensional integrated fabrication of microchannels in microfluidic chips.

Such processes demonstrate unique value in bio-detection and optical metamaterial preparation.

However, their large-scale application remains constrained by the challenge of balancing processing efficiency and equipment costs.

Smart Manufacturing Process Integration

Smart Manufacturing Process Integration leverages an Industrial Internet of Things (IIoT) architecture to establish a multi-dimensional perception and autonomous decision-making system for process parameters.

This enables full lifecycle optimization of machining processes.

By deploying vibration sensors, infrared thermal imagers, and acoustic emission detection devices, the system captures real-time critical parameters.

These include machine tool spindle vibration spectra, workpiece temperature rise gradients, and tool wear status.

It then performs multi-physics coupling simulations based on digital twin models to predict the development trends of machining defects.

During dynamic compensation, the intelligent control system adjusts servo motor torque output via fuzzy PID algorithms to counteract cutting force fluctuations caused by tool dulling.

Simultaneously, a temperature compensation module corrects geometric errors resulting from thermal deformation.

Furthermore, the integration of a process knowledge graph enables equipment to autonomously access historical machining data.

It can recommend optimal cutting parameter combinations for similar part features, reducing manual trial-and-error costs.

At the production line level, the intelligent manufacturing system achieves information interconnection between machining units and AGV logistics systems via the OPC-UA protocol.

This forms a fully closed-loop control process from blank loading to finished product inspection.

Core Methods of Precision Machining Technology

Ultra-Precision Machining Technology

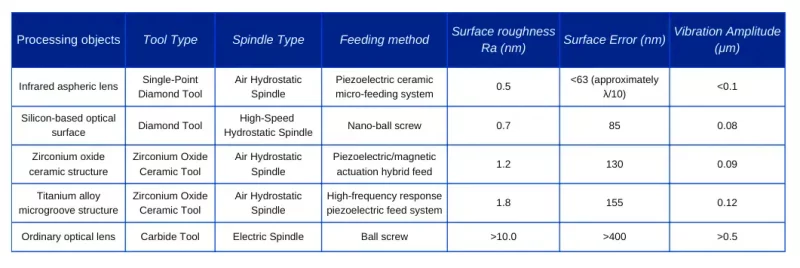

Ultra-precision machining technology achieves sub-micron machining accuracy.

It also attains nanometer-level surface roughness through the coordinated control of air-bearing spindles and nano-level feed systems.

The micro-vibration amplitude of air-bearing spindles can be controlled within 0.1μm.

Combined with piezoelectric ceramic-driven feed systems, this ensures stable contact between the tool and workpiece during high-speed rotation.

Diamond tools, leveraging their high thermal conductivity and extreme hardness, suppress microcrack propagation during machining of hard and brittle materials like silicon and ceramics. This reduces surface roughness to Ra < 1 nm.

For instance, in infrared optical component machining, single-point diamond turning technology—through optimized tool geometry and cutting path planning—enables direct forming of aspheric lenses with surface accuracy errors controlled within λ/10 (λ=632.8nm).

Furthermore, the application of zirconia ceramic tools in microstructure machining of titanium alloys has expanded the material applicability of ultra-precision technology.

These tools exhibit reduced edge chipping compared to traditional cemented carbide tools, providing technical assurance for the mass production of precision molds and optical components.

A comparison of ultra-precision machining parameters and performance is shown in Table 2.

Non-Traditional Processing Technologies

Non-traditional processing technologies achieve material removal through physicochemical energy interactions, circumventing the mechanical limitations of conventional machining.

Femtosecond laser processing utilizes the nonlinear absorption effect generated by ultra-short pulses to create micro-hole arrays on metal surfaces such as stainless steel and titanium alloys.

This process occurs without a heat-affected zone, and the hole diameter consistency deviation is less than 2 μm.

In cold processing mode, material removal occurs via direct sublimation rather than melting, eliminating recast layers and microcrack defects.

Electrochemical machining, based on anodic dissolution principles, precisely controls parameters through customized cathode tools and electrolyte formulations.

This enables the fabrication of irregular microchannels with aspect ratios exceeding 20:1 on curved nickel-based high-temperature alloy components, achieving wall surface roughness Ra ≤ 0.2μm.

For silicon carbide composite machining, electrolytic grinding combines electrochemical softening with mechanical grinding.

This achieves material removal rates over three times higher than conventional grinding while eliminating subsurface damage layers.

This technology is widely applied in manufacturing air film holes for aeroengine blades and microchannels for fuel cell bipolar plates.

Online Inspection and Compensation Technology

Online inspection and compensation technology establishes a real-time correction mechanism for machining errors through multi-source sensor data fusion.

A machine vision system based on high-resolution industrial cameras synchronously extracts workpiece contour features during machining.

Sub-pixel edge detection algorithms achieve online measurement with dimensional accuracy of ±1 μm.

Upon detecting machining deviations, adaptive compensation algorithms dynamically adjust position commands in CNC code based on tool wear prediction models and thermal error mapping relationships.

For instance, in five-axis machining, a composite measurement system combining laser interferometers and ballbar instruments provides real-time feedback on geometric errors of moving axes.

Through backlash compensation and pitch error correction, spatial positioning accuracy is enhanced to within 5μm/800mm.

Figure 1 illustrates the comparison of machining errors before and after online detection and compensation.

Challenges and Countermeasures in Technology Application

Analysis of Technical Difficulties

The application of current precision machining technology faces multiple technical bottlenecks.

The inadequacy of certain performance metrics in core components of high-precision equipment is particularly prominent.

Taking ultra-precision bearings as an example, their radial runout must be controlled within 0.05μm.

However, the dynamic stiffness and service life metrics of some products consistently outperform other components by over 30%, resulting in ongoing dependency on high-end machine tools.

Environmental disturbances significantly impact machining stability.

For instance, when workshop temperature and humidity fluctuate beyond ±1°C and ±5%, respectively, thermal expansion effects in cast iron bed bodies can degrade machining center positioning accuracy by 15μm/m.

Furthermore, non-uniform residual stress distribution on workpiece surfaces exacerbates dimensional drift.

Furthermore, process parameter optimization under multi-physics coupling lacks universal models.

For instance, in laser-electrolytic hybrid machining, the interaction mechanism between plasma shock waves and electrolyte flow fields remains incompletely understood.

This narrows the process window and limits synergistic improvements in machining efficiency and surface quality.

Such issues constrain the reliability of process prediction and control under complex operating conditions.

Process Optimization Pathway

To address existing technological bottlenecks, a systematic solution must be developed from both theoretical innovation and engineering practice dimensions.

At the fundamental research level, molecular dynamics simulations and high-speed imaging techniques should be employed.

These tools help establish models for dislocation propagation and crack growth during the machining of hard, brittle materials.

This will reveal the energy transfer mechanisms at the tool-workpiece interface, providing theoretical support for process parameter optimization.

For process standardization, big data analytics can integrate multi-source data—including cutting forces, tool wear, and surface integrity.

This helps build a knowledge base of machining parameters for typical material-structure combinations.

For instance, a five-axis milling parameter recommendation system for titanium alloy impellers can reduce process debugging cycles by over 50%.

Environmental disturbance suppression requires active control strategies.

For instance, an active vibration damping system based on magnetic levitation actuators can suppress machine tool vibration amplitude to within 0.2 μm/s².

Meanwhile, thermally isolated vibration-isolated bases utilize liquid-circulating temperature control modules to maintain machining zone temperature fluctuations within ±0.1°C.

Such integrated technologies significantly enhance the environmental robustness of machining systems, propelling precision manufacturing toward industrial-scale application.

Conclusion

The evolution of modern mechanical manufacturing processes has shifted from singular precision enhancement to systematic technological integration.

Breakthroughs in precision machining technology have become the core driving force propelling the transformation and upgrading of the manufacturing industry.

Research indicates that integrated machining techniques significantly shorten production cycles through multi-process integration.

The dynamic error compensation mechanism in five-axis machining centers controls deformation in thin-walled components to within the micrometer range.

Micro-nano manufacturing technologies, leveraging ultra-precision machine tools and ion beam etching processes, enable controlled formation of sub-micrometer structures, laying the foundation for miniaturized device fabrication.