Blog

More to learn about rapid prototyping and manufacturing industry.

Research on the Error Control Method for Five-Axis CNC Machine Tool Machining based on Digital Twin

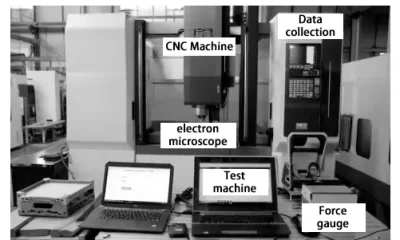

Five-axis CNC machines are widely used in high-precision complex surface machining, characterized by multiple interconnected axes and frequent tool orientation changes, making machining accuracy susceptible to various disturbances.

Practical Exploration of Automation Technology in Machining Manufacturing

The machinery manufacturing industry serves as a pillar of the national economy, with its development level directly impacting the nation's overall competitiveness.

Effect of Laser Shock Treatment on Bending Deformation of 301L Stainless Steel

With the rapid development of rail transit, the comprehensive performance requirements for rail vehicle materials are increasingly demanding.

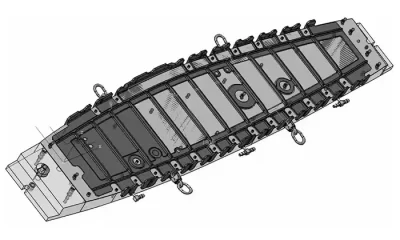

Digital Twin–Driven Optimization for Intelligent Manufacturing of Die-Cast Aluminum Parts

The demand for lightweighting in new energy vehicles has accelerated the adoption of large-sized aluminum die-cast components.

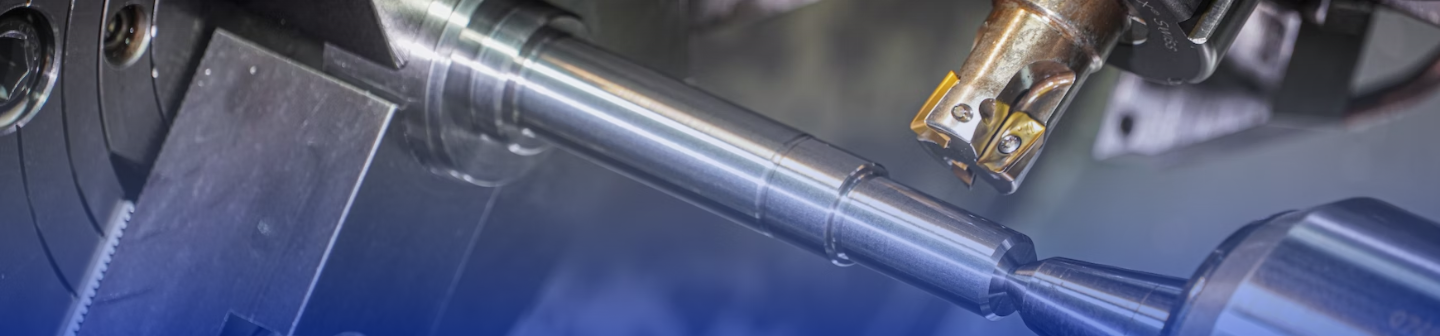

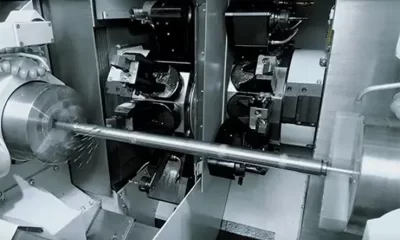

Slender Shaft Turning Techniques for High-Precision Machining

Slender shaft turning is a high-precision CNC machining process focused on controlling deformation, vibration, and thermal effects in

Dynamic Milling and Regional Machining Path Optimization

In many cases, milling toolpaths still follow traditional approaches. Failure to fully leverage the advantages of tool length results in redundant machining, where only the tool's minimal height is utilized.

Gradient Helical End Mills for High-Precision Titanium Alloy Machining

To meet the lightweight requirements of aerospace components, titanium alloys are widely adopted in thin-walled structural parts. However, the inherent low stiffness of thin-walled structures, coupled with their difficult-to-machine characteristics, leads to issues such as deformation and vibration during manufacturing.

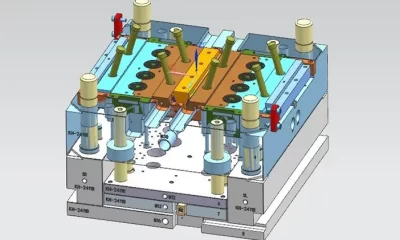

Injection Mold Design for High-Quality Electric Mosquito Coil Heater Plastic Covers

Electric mosquito coil heaters are common household items in people's daily lives. Their plastic casing components must be aesthetically pleasing, durable, and safe.

CNC Machining Process: A Step-by-Step Guide from Design to Finished Part

The CNC machining process is a fully digital, step-by-step manufacturing workflow that transforms CAD designs into high-precision parts through automated, subtractive machining.

Application of Dynamic Milling on Machines with Legacy CNC Systems

High-speed dynamic milling has gained widespread adoption in rough machining applications due to its significant advantages: high efficiency, low machine tool load, minimal tool wear, and intelligent programming.

Research on High-speed Milling Processing Technology of Beam-Rib in Aircraft Wing Box

Currently, high-speed milling is widely applied in the aerospace manufacturing industry due to its unique advantages of high precision, high efficiency, low cutting forces, and superior surface quality.

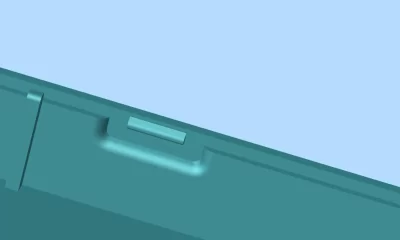

Design Standards for Latching Positions and Stop Grooves

Designing effective latching positions, stop grooves, and snap-fit structures is essential for ensuring the structural integrity, assembly efficiency, and durability of plastic and rubber components.