China CNC Milling » Blog » Mechanical Testing – Importance, Methods, and Applications

FAQ

What materials can you work with in CNC machining?

We work with a wide range of materials including aluminum, stainless steel, brass, copper, titanium, plastics (e.g., POM, ABS, PTFE), and specialty alloys. If you have specific material requirements, our team can advise the best option for your application.

What industries do you serve with your CNC machining services?

Our CNC machining services cater to a variety of industries including aerospace, automotive, medical, electronics, robotics, and industrial equipment manufacturing. We also support rapid prototyping and custom low-volume production.

What tolerances can you achieve with CNC machining?

We typically achieve tolerances of ±0.005 mm (±0.0002 inches) depending on the part geometry and material. For tighter tolerances, please provide detailed drawings or consult our engineering team.

What is your typical lead time for CNC machining projects?

Standard lead times range from 3 to 10 business days, depending on part complexity, quantity, and material availability. Expedited production is available upon request.

Can you provide custom CNC prototypes and low-volume production?

Can you provide custom CNC prototypes and low-volume production?

Hot Posts

Introduction to Mechanical Testing

Definition & Purpose

Mechanical testing is the process of evaluating the mechanical properties of materials and components to determine their performance under defined conditions. These tests simulate the types of forces and stresses materials will encounter during manufacturing, assembly, and service life. The primary goal is to ensure that materials perform reliably, safely, and efficiently within their intended applications.

Importance

In modern manufacturing, mechanical testing is vital to validating product design, optimizing production processes, and ensuring compliance with industry standards and safety requirements. Whether developing high-performance alloys for aerospace or verifying plastic components for consumer products, mechanical testing underpins quality control and failure prevention.

Testing plays a pivotal role in:

- Design verification

- Regulatory compliance (e.g., ASTM, ISO)

- Component reliability and durability

- Root cause analysis in failure investigations

Role in Engineering and Material Science

Mechanical testing bridges the gap between theoretical material science and real-world application. Engineers use data from mechanical tests to:

- Select materials based on performance criteria

- Inform finite element analysis (FEA) and simulation inputs

- Optimize product geometry and manufacturing methods

- Support innovation in materials and processes

- Enable lifecycle analysis and sustainability assessments

Key Mechanical Properties Measured

Mechanical testing methods quantify a wide array of material properties critical to engineering design and structural integrity. The most common include:

- Tensile, Compressive, and Shear Strength: Assess material load-bearing capabilities under different types of stress.

- Surface Hardness: Indicates resistance to indentation and wear.

- Ductility: The material’s ability to plastically deform without fracturing.

- Toughness: Capacity to absorb energy before fracture, especially under sudden loads.

- Fatigue Resistance: Durability under repetitive loading cycles.

- Fracture Toughness: Resistance to crack propagation under stress.

- Elastic Modulus and Poisson’s Ratio: Reflect stiffness and transverse strain behavior under axial loads.

- Creep Resistance: Stability under long-term loading at elevated temperatures.

- Corrosion Resistance: Ability to resist material degradation in reactive environments.

- Brittleness and Plasticity: Indicators of how materials will behave under stress, impact, or deformation.

Understanding these properties enables engineers to make data-driven decisions during product development, qualification, and lifecycle management.

Common Mechanical Testing Methods

Tensile Testing

Tensile testing involves pulling a specimen until it fractures. This method evaluates:

- Tensile and yield strength

- Elongation (ductility)

- Elastic modulus (stiffness)

It also produces a stress-strain curve, revealing critical insights into the material’s behavior during elastic and plastic deformation.

Standards: ASTM E8/E8M, ISO 6892-1

Compression Testing

This test compresses a specimen to evaluate its ability to withstand crushing forces. It is essential for materials used in load-bearing or structural applications.

Measurements include:

- Compressive strength

- Modulus of elasticity under compression

- Deformation and buckling behavior

Standards: ASTM E9 (metals), ASTM D695 (plastics)

Hardness Testing

Hardness tests determine a material’s resistance to localized plastic deformation. Common methods include:

- Brinell: For coarse structures and castings.

- Rockwell: Rapid and versatile, suitable for production environments.

- Vickers & Knoop: Ideal for small or thin samples.

- Shore Durometer: Used for polymers and elastomers.

Standards: ASTM E10 (Brinell), ASTM E384 (Vickers/Knoop), ISO 6508 (Rockwell)

Impact Testing

Impact tests assess a material’s toughness—the ability to absorb energy during a sudden shock or blow.

- Charpy V-Notch Test: Common for metals, especially at sub-zero temperatures.

- Izod Test: Used in plastics and composites.

These tests are crucial for applications prone to impact or sudden loading.

Standards: ASTM E23, ISO 179

Fatigue Testing

Fatigue testing exposes a specimen to cyclic loading to identify its endurance limit and lifespan under fluctuating stress levels.

Outputs include S-N curves, which plot stress against the number of cycles to failure.

Standards: ASTM E466, ISO 1099

Fracture Mechanics Testing

Used to evaluate materials with inherent flaws or cracks, these tests predict how cracks initiate and propagate under load.

Methods include:

- KIc (Linear Elastic Fracture Toughness)

- JIc (Elastic-Plastic Fracture Toughness)

- CTOD (Crack Tip Opening Displacement)

Standards: ASTM E399, ASTM E1820

Additional Testing Methods

- Torsion Testing: Measures shear strength under twisting.

- Creep Testing: Determines deformation under sustained load at elevated temperatures.

- Non-Destructive Testing (NDT): Uses ultrasonic, radiographic, magnetic, and acoustic methods to evaluate internal flaws without damaging the specimen.

- Specialized Testing: Includes DMA (dynamic mechanical analysis), tribological testing (wear and friction), flexural, peel, and shear tests for specific use-cases in advanced manufacturing and R&D.

Practical Considerations in Mechanical Testing

Effective mechanical testing requires a controlled and consistent approach. Engineers and quality professionals must consider:

Testing Environment

Test conditions should reflect actual service environments. Parameters like temperature, humidity, and chemical exposure are controlled to simulate real-world operating conditions and provide relevant data.

Sample Preparation

Correct specimen geometry and surface finish are essential for valid results. Preparation must follow established protocols such as ASTM or ISO to ensure repeatability and standardization.

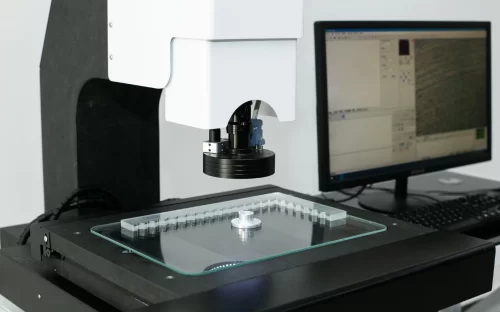

Equipment

Modern mechanical testing relies on a suite of calibrated machines and tools:

- Universal Testing Machines (UTMs)

- Fatigue testers

- Hardness and impact testers

- Advanced NDT systems

Regular calibration and maintenance are crucial for ensuring data accuracy.

Testing Responsibility

Mechanical testing is typically conducted by:

- In-house QA/QC teams

- Independent certified laboratories

- Specialized service providers for advanced or regulated testing

Selecting the right testing partner ensures compliance and credibility.

Documentation

Thorough documentation is non-negotiable. Detailed reports, Mill Test Certificates (MTCs), and Material Test Reports (MTRs) must be maintained to ensure traceability, satisfy regulatory audits, and provide historical data for product lifecycle decisions.

When and Why to Perform Mechanical Testing

Material Selection & Design

In the early stages of product development, mechanical testing is indispensable for selecting materials that align with design specifications and operational demands. Whether optimizing for strength, ductility, fatigue resistance, or corrosion behavior, engineers use test data to evaluate candidate materials and validate theoretical assumptions before committing to full-scale manufacturing.

Manufacturing Quality Control

During production, mechanical testing serves as a gatekeeper to ensure that raw materials and finished components meet required mechanical standards. Quality control testing helps detect inconsistencies such as variations in heat treatment, improper alloying, or manufacturing defects—preventing substandard products from entering the supply chain.

Post-Production Validation

After components are manufactured and assembled, mechanical tests may be conducted on representative samples to confirm that performance characteristics conform to the design intent and regulatory standards. This validation phase is particularly critical in safety-critical industries like aerospace, automotive, and medical devices.

Maintenance & Life Assessment

For assets in service, mechanical testing—especially when combined with non-destructive techniques—can monitor material degradation over time. Evaluating changes in toughness, fatigue resistance, or corrosion behavior enables engineers to plan maintenance schedules, reduce unplanned downtime, and extend equipment life safely.

Failure Investigation

When failures occur, mechanical testing plays a central role in forensic analysis. By re-testing material properties from failed components, engineers can identify whether the root cause lies in the material, design, processing, or environmental factors. These insights are invaluable for corrective actions and improving future designs.

Benefits and Applications

Mechanical testing delivers a wide range of benefits that support technical, regulatory, and business objectives:

- Ensures Product and Structural Safety: Confirms that materials can endure operational stresses without failure.

- Supports Regulatory and Industry Compliance: Aligns manufacturing outputs with standards like ASTM, ISO, and BS, facilitating market entry and certification.

- Guides Product Development: Informs design engineers and material scientists in developing lighter, stronger, and more durable products.

- Facilitates Risk Mitigation: Enables early identification of material weaknesses, reducing liability and improving safety.

- Enhances Component Longevity: Helps select and verify materials that resist fatigue, wear, and environmental degradation.

- Supports R&D and Innovation: Provides empirical data to validate simulations, develop new materials, and refine manufacturing processes.

Applications span nearly every industry—from aerospace and automotive to construction, electronics, and biomedical engineering—making mechanical testing a universal tool in engineering practice.

Challenges and Limitations

Despite its advantages, mechanical testing is not without its constraints:

- Destructive Nature of Many Tests: Many mechanical tests irreversibly damage the specimen, making them unsuitable for final-use parts.

- Limited Real-World Simulation: Standardized testing may not fully replicate the complex, multiaxial, and dynamic loads found in actual service conditions.

- Specialized Requirements: Accurate testing depends on highly trained personnel, rigorous procedures, and precision-calibrated equipment.

- Cost and Time Considerations: High-frequency or specialized testing can be time-consuming and expensive, especially in R&D environments.

- Sensitivity to Sample Preparation: Improper machining, surface finish, or misalignment can skew results, compromising data integrity.

These challenges underscore the importance of methodical planning, skilled execution, and supplementing testing with complementary techniques.

Emerging Alternatives and Complementary Techniques

As technology evolves, mechanical testing is increasingly supported by advanced tools and predictive models:

Computational Modeling & FEA

Finite Element Analysis allows engineers to simulate mechanical behavior under various loading conditions, reducing reliance on physical prototyping. FEA is particularly effective when calibrated with empirical test data, combining simulation efficiency with testing accuracy.

Non-Destructive Evaluation (NDE)

NDE methods—such as ultrasonic testing, radiography, and acoustic emission analysis—detect flaws and monitor degradation without damaging the component. These techniques are vital for in-service inspection and preventive maintenance.

Predictive Maintenance and Digital Twins

By integrating mechanical test data with real-time sensor feedback, engineers can develop digital twins—virtual replicas of physical systems. These models enable predictive maintenance, optimize performance, and reduce downtime by forecasting material fatigue and failure.

These innovations do not replace traditional mechanical testing but rather extend its value by enabling continuous monitoring and smarter decision-making.

Conclusion

Mechanical testing remains a cornerstone of materials engineering and manufacturing. It provides tangible, quantifiable evidence of a material’s suitability for its intended application, guiding engineers throughout the product lifecycle—from concept and design to deployment and end-of-life assessment.

Despite the rapid growth of simulation, machine learning, and sensor-driven analytics, physical mechanical testing continues to offer unmatched insights into how materials perform under real-world conditions. For industries focused on quality, safety, and performance, it is not just a technical requirement—it is a strategic necessity.

As manufacturing continues to advance with Industry 4.0, integrating mechanical testing with digital tools and data analytics will unlock new levels of efficiency, reliability, and innovation.